Sealing film

An encapsulation film and encapsulation layer technology, applied in electronic equipment, applications, electrical components, etc., can solve problems such as the occurrence of OLED bright spots, and achieve the effect of preventing bright spots and improving process efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] Fabrication of the magnetic layer

[0106] Fe particles (particle diameter about 1 μm to 10 μm, flake type) as magnetic particles were mixed with acrylic resin as binder resin in a weight ratio of 90:10 (magnetic particles: binder resin) to prepare dilute with toluene solution (50% solids).

[0107] The solution prepared above was applied to the release surface of the release PET using a comma coater, and dried in a dryer at 130° C. for 3 minutes to form a magnetic layer having a thickness of 30 μm.

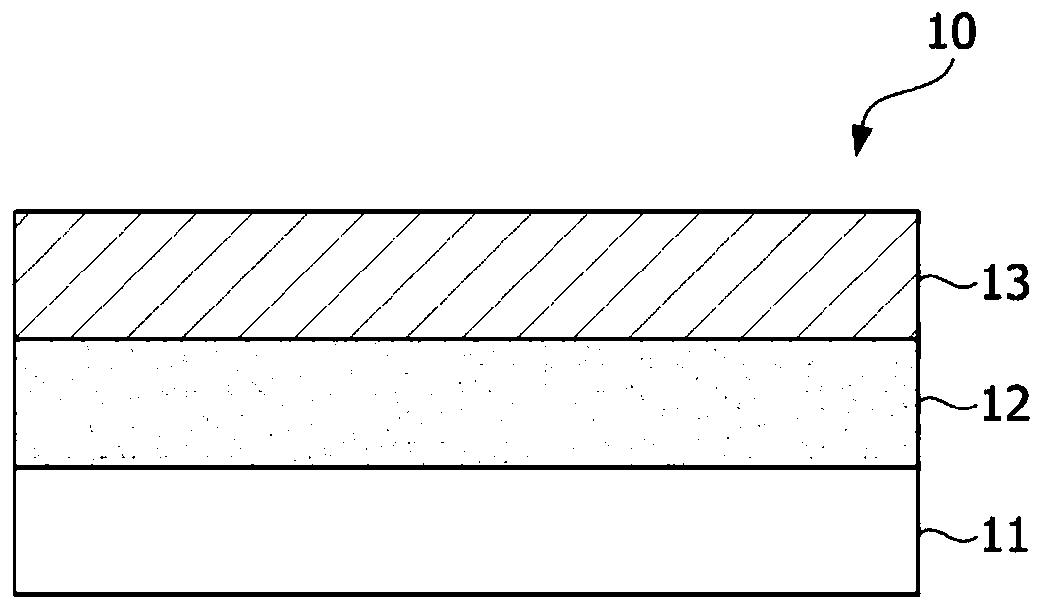

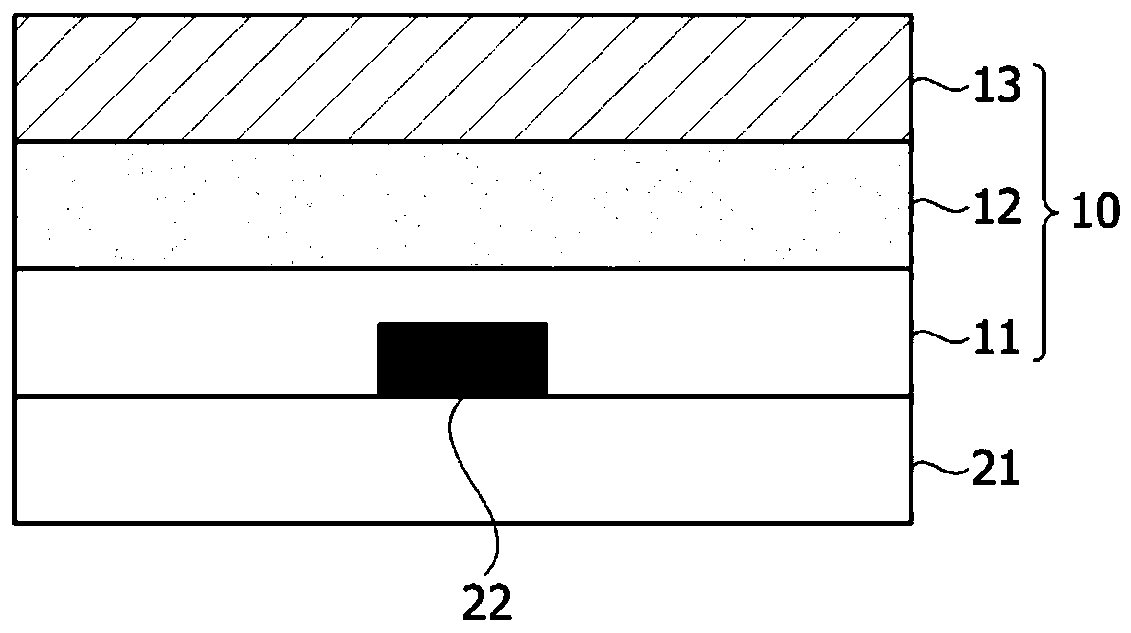

[0108] Manufacture of encapsulation layer

[0109] A CaO (average particle size 3 μm) solution (solid content 50%) was prepared as a moisture adsorbent. Solutions (solid content 50%) in which 200 g of butyl rubber resin (BT-20, Sunwoo Chemtech) and 60 g of DCPD petroleum resin (SU5270, Sunwoo Chemtech) were diluted with toluene were prepared separately, and then the solutions were homogenized. Introduce 10 g of photocuring agent (TMPTA, Miwon) and 15 g of photoiniti...

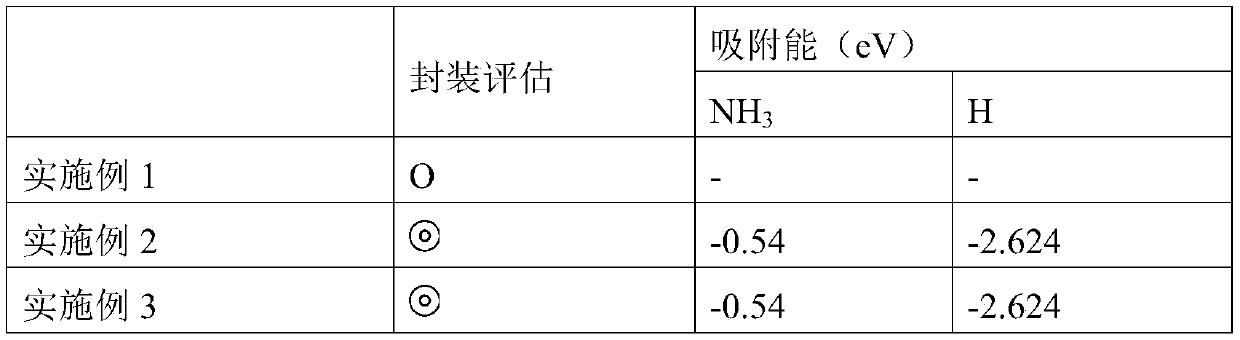

Embodiment 2

[0116]An encapsulation film was produced in the same manner as in Example 1, except that Fe particles (particle diameter about 1 μm to 10 μm, flake type) as magnetic particles were mixed with Ni as a bright spot suppressor in the production of the magnetic layer. Particles (particle diameter about 300nm) were mixed at a weight ratio of 9:1, and acrylic resin as a binder resin was mixed with magnetic particles and bright spot suppressor at a ratio of 90:10 (magnetic particle + bright spot suppressor: binder resin ) in a weight ratio to prepare a solution diluted with toluene (50% solid content), and then form a magnetic layer.

Embodiment 3

[0118] An encapsulation film was manufactured in the same manner as in Example 2, except that the magnetic particles and the bright spot suppressor were mixed in a weight ratio of 6:4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com