Connecting device and method for ceramic biscuits

A technology of ceramic green body and connecting device, applied in lamination device, ceramic molding machine, chemical instrument and method, etc., can solve problems such as poor connection effect, achieve easy operation, ensure continuity and reliability, and compensate for position movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

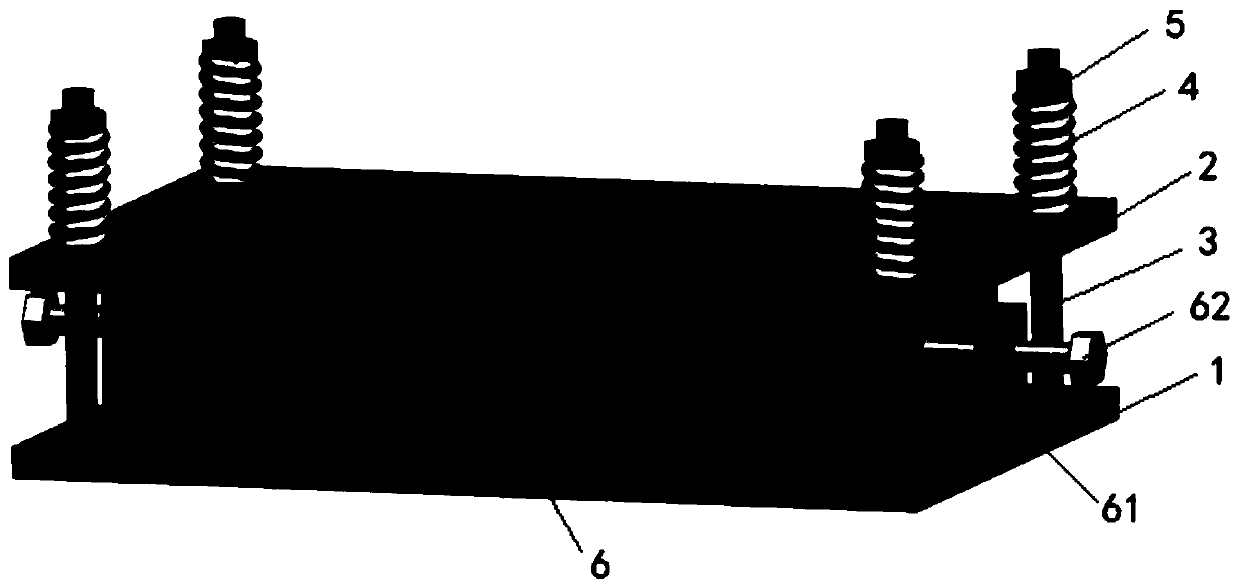

[0045] Such as figure 1 As shown, it is a structural schematic diagram of a ceramic green body connecting device according to an embodiment of the present invention, which is used for connecting two square flat ceramic green bodies of the same size and shape, including a lower support part 1 for placing a square flat ceramic green body, The lower supporting part 1 is a square plate structure, and its size is larger than that of the square plate ceramic green body.

[0046] An upper support part 2 having the same size as the lower support part is provided above the lower support part 1, and the lower support part 1 and the upper support part 2 overlap in plan view angle, and the ceramic green body after docking is placed Between the lower supporting part 1 and the upper supporting part 2 .

[0047] The four corners of the lower support part 1 are respectively fixedly connected with screw rods 3, and the corresponding positions of the upper support part 2 are respectively provi...

Embodiment 2

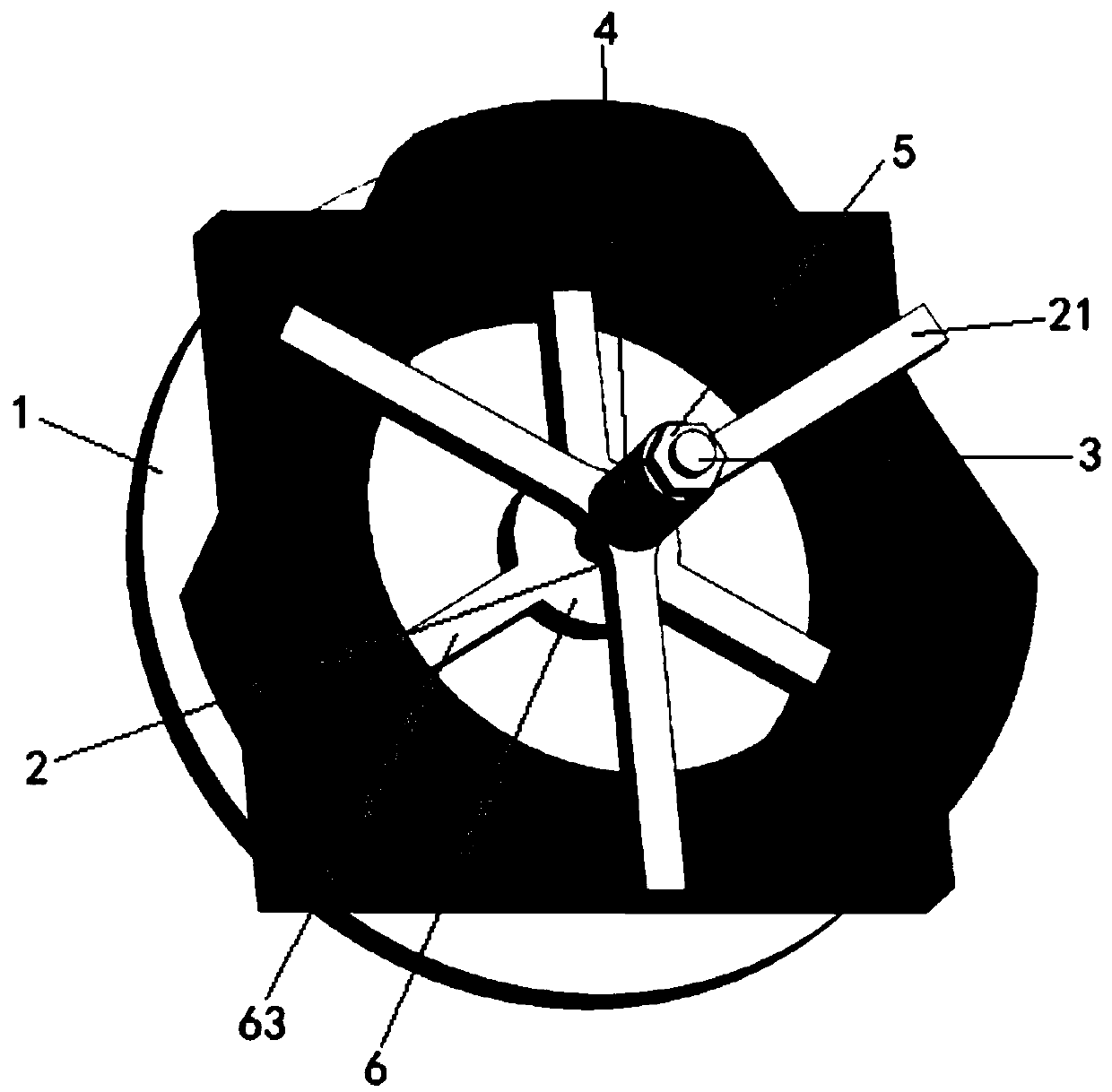

[0060] Such as figure 2 As shown, it is a structural schematic diagram of a ceramic green body connecting device according to another embodiment of the present invention, which is used for connecting flat ceramic green bodies with central circular holes of the same size, including a lower support part for placing flat ceramic green bodies 1. The lower supporting part 1 is a circular plate structure.

[0061] A screw rod 3 is fixedly connected to the center of the lower supporting part 1, and a stopper 6 is provided on the screw rod 3 to control the butt joint accuracy of two flat ceramic green bodies, so as to avoid the gap between the two flat ceramic green bodies after docking. sliding relative to each other.

[0062] An upper support part 2 is also provided on the screw rod 3, and the butted ceramic green body is placed between the lower support part 1 and the upper support part 2; a spring 4 and a spring 4 are also provided on the screw rod 3. Nut 5, the spring 4 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com