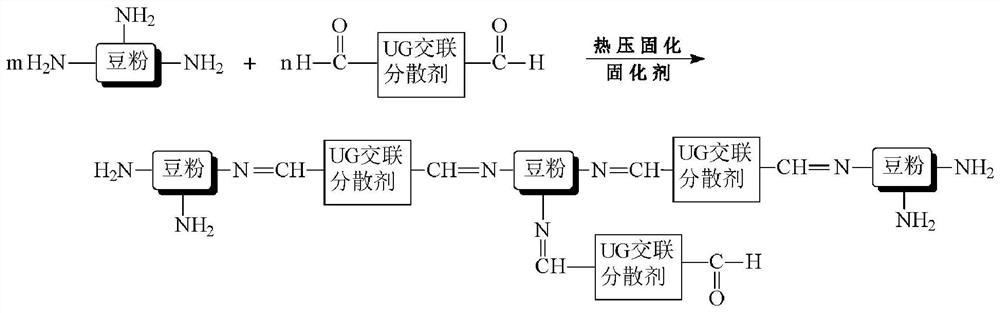

Soybean Adhesive Prepared Using Low-Cost and Formaldehyde-Free Crosslinked Dispersant

A soybean adhesive and dispersant technology, which is applied in the preparation of adhesives, animal glue or gelatin, and polymer adhesive additives, etc., can solve the problems that wood-based panels cannot meet the requirements of formaldehyde emission and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment one: the preparation method of a kind of low-cost and formaldehyde-free cross-linking dispersant of this embodiment, it is finished according to the following steps:

[0026]1. Weigh 50 to 165 parts of water, 80 to 150 parts of glyoxal solution with a mass percentage of 20% to 50% and 10 to 32 parts of urea by weight, and weigh 80 to 150 parts Mix the glyoxal solution with a mass percentage of 20% to 50% and weighed 50 to 165 parts of water evenly, then adjust the pH to 8.5 to 9.5 at room temperature, and stir to raise the temperature to 50°C to 80°C. 8.5 ~ 9.5 and the temperature is 50 ℃ ~ 80 ℃, add 10 ~ 32 parts of urea weighed to obtain the reaction system, the reaction system is heated to 50 ~ 80 ℃ within 25min ~ 35min, and the temperature is Under the condition of 50°C-80°C, heat-preserve the reaction until the reaction system is dripped into water at 19°C-21°C to form cloudy insoluble matter, then stop the heat-retaining reaction to obtain a cr...

specific Embodiment approach 2

[0036] Embodiment 2: This embodiment differs from Embodiment 1 in that the molar ratio of glyoxal to urea is (2.0-2.4):1 when preparing the cross-linked dispersant described in step 1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in step 1, a sodium hydroxide solution with a mass percentage of 10% to 40% is used to adjust the pH to 8.5 to 9.5 at room temperature. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com