Slope protection plate and flexible connection protection face system

A flexible connection and flexible connector technology, applied in coastline protection and other directions, can solve the problems of poor overall stability and high cost of use, and achieve the effects of reducing demand, improving overall stability and flexibility, and improving convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

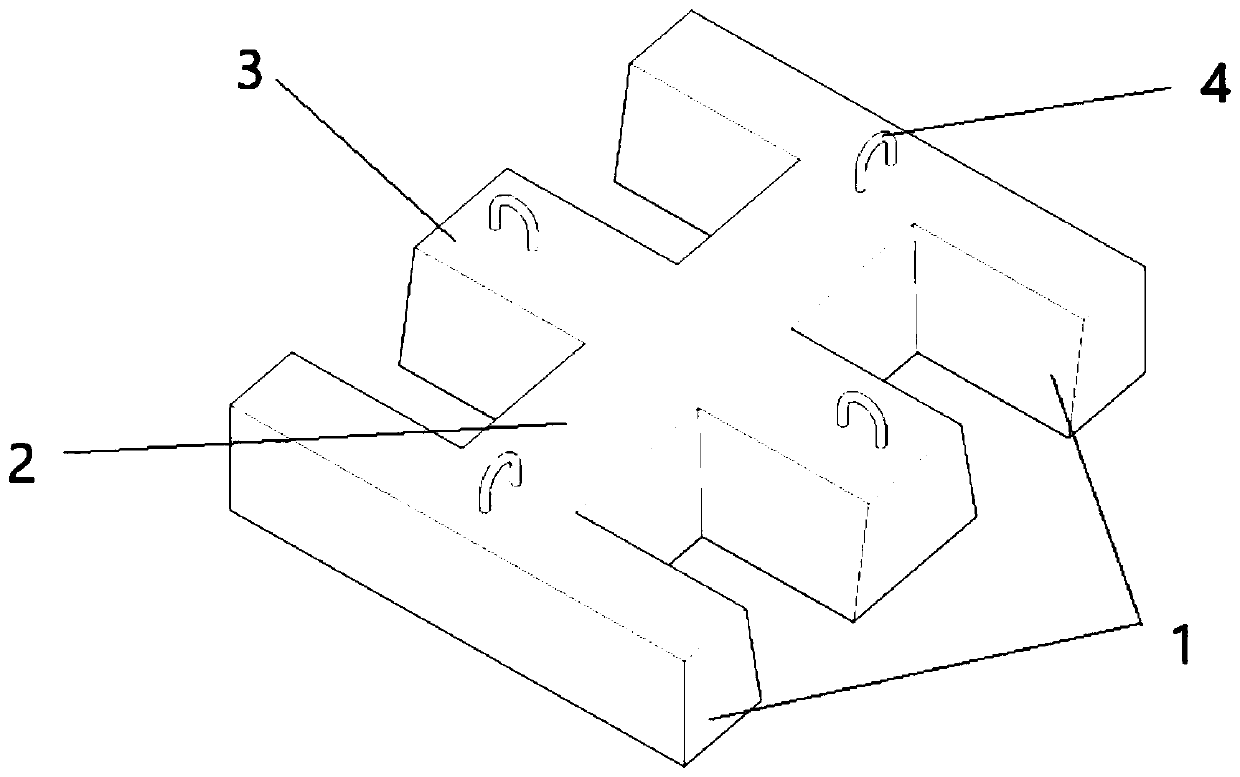

[0038] combine figure 1 and figure 2 , a slope protection plate, comprising an end plate 1, a longitudinal plate 2 and a middle plate 3, the end plate 1, the longitudinal plate 2 and the middle plate 3 are elongated concrete plates, the end plate 1, the longitudinal plate 2 and the middle plate 3 The lengths of the end plates 1 and the middle plates 3 are equal in length, two end plates 1 are arranged in parallel, the longitudinal plates 2 are perpendicular to the end plates 1, and the longitudinal plates 2 are arranged between the two end plates 1 And connect the middle parts of the two end plates 1, one end of the longitudinal plate 2 is connected to the middle part of one end plate 1, the other end of the longitudinal plate 2 is connected to the middle part of the other end plate 1, and the middle plate 3 is arranged between the two end plates 1 , the middle plate 3 is parallel to the end plate 1, the middle part of the middle plate 3 is fixedly connected with the longitu...

Embodiment 2

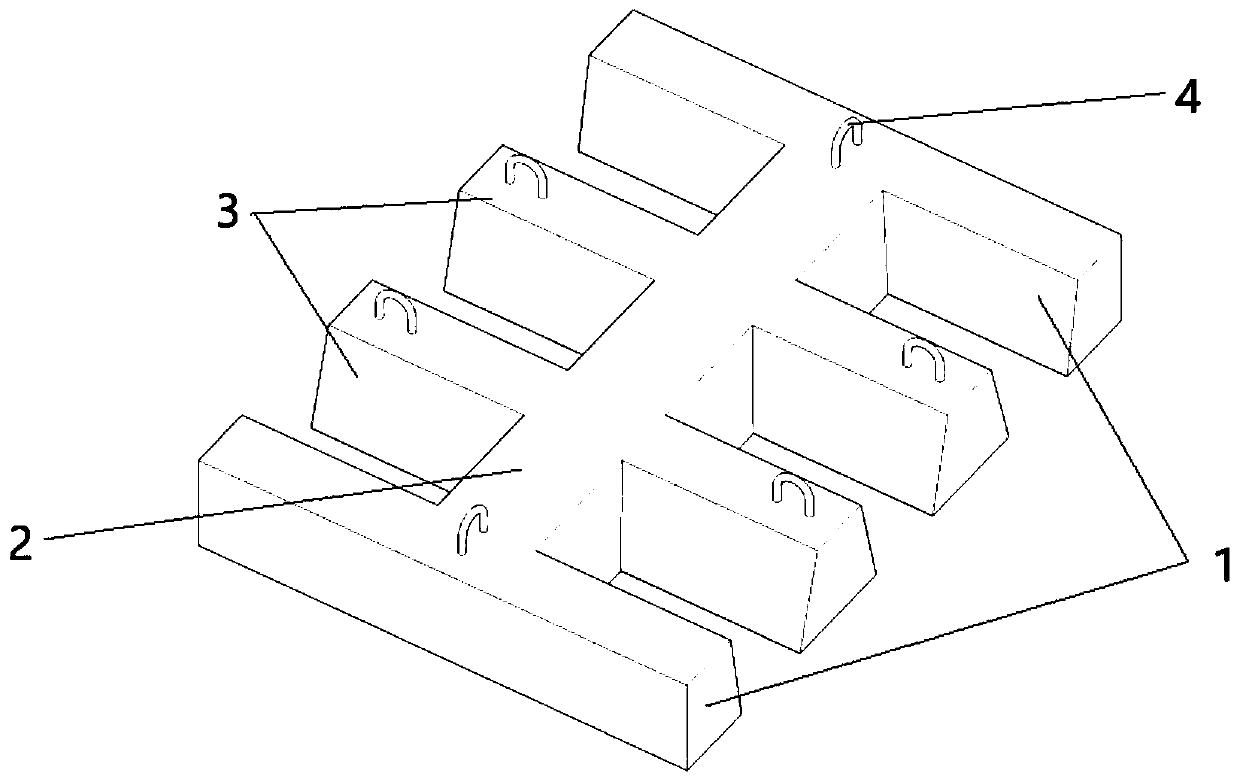

[0045] combine image 3 The difference between this embodiment and Embodiment 1 is that the number of intermediate plates 3 is different. In this embodiment, there are two intermediate plates 3, and the distance between the two intermediate plates 3 is the same as that between the end plate 1 and the end plate 1 to The intervals between adjacent middle plates 3 are the same, and the middle parts of the two middle plates 3 are connected with the longitudinal plates 2 . In this arrangement, increasing the number of intermediate plates 3 can correspondingly increase the number of tie rods 4 on the intermediate plates 3, so that the connection between slope protection plates can be more stable.

Embodiment 3

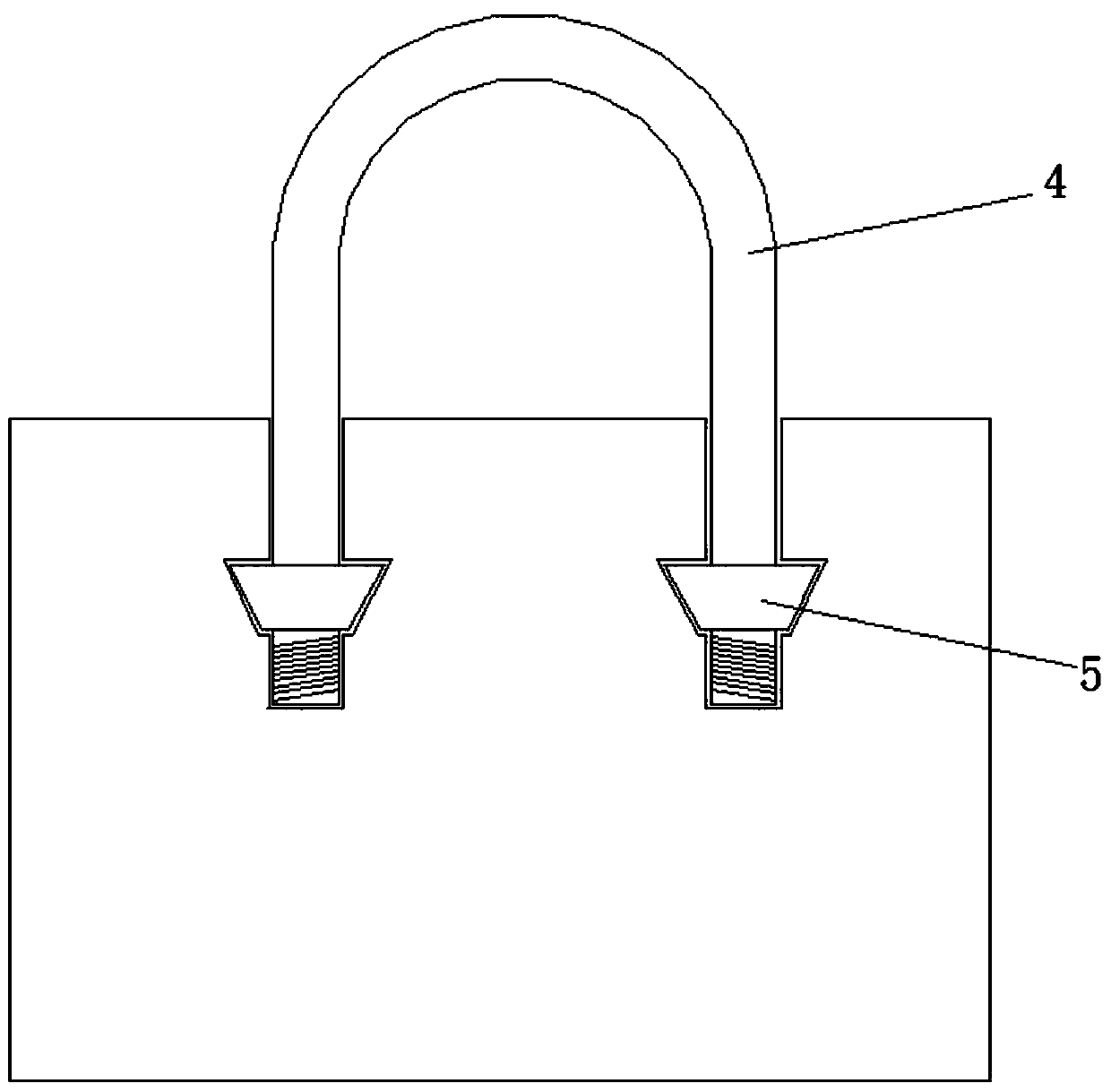

[0047] combine Figure 4 , This embodiment differs from Embodiment 1 in that the structure of the pull rod 4 is different.

[0048]In this embodiment, the two ends of the pull rod 4 are respectively provided with bending parts 41, which are formed by bending two straight rods of the pull rod 4, and the bending angle can be 90° or 180°. Located in the end plate 1, the longitudinal plate 2 or the middle plate 3, the bent portion 41 can effectively increase the firmness of the tie rod 4, and has the advantages of simple production, good firmness and low production cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com