Exhaust and scavenging system of two-stroke diesel engine

A technology of scavenging system and diesel engine, which is applied in the direction of exhaust gas treatment, exhaust device, mechanical equipment, etc. It can solve the problems of large space occupied by the post-processing unit and economic impact, and achieve the effect of increasing the efficiency of exhaust gas removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

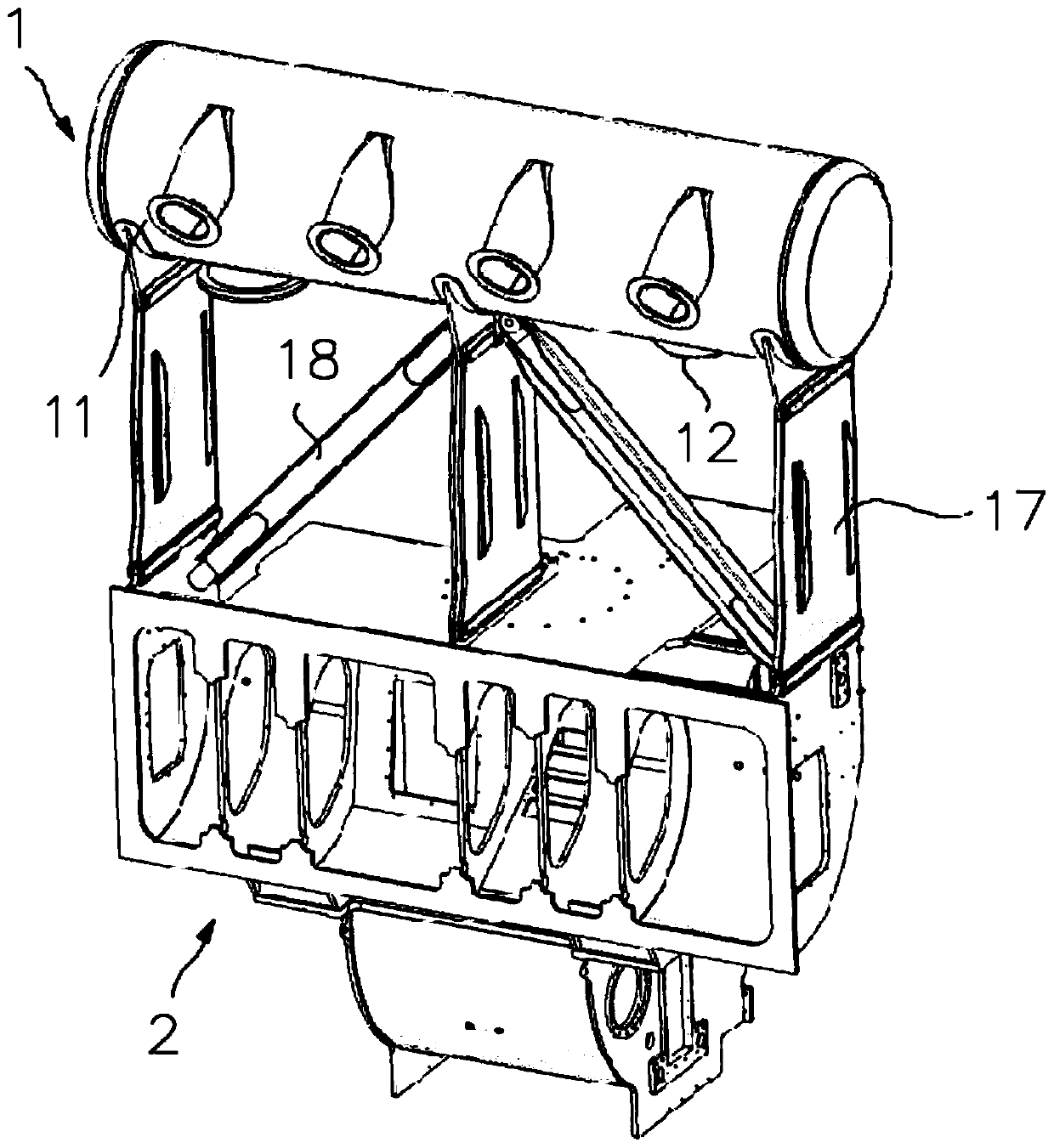

[0039] Such as figure 1 As shown, the exhaust and scavenging system of a two-stroke diesel engine provided by the present invention includes an exhaust device 1 and a scavenging device 2, and both the exhaust device 1 and the scavenging device 2 are connected with the main engine of the two-stroke diesel engine.

[0040] It should be noted that the main engine includes a welded base, a frame and a casted cylinder block, and the scavenging method of the main engine is DC scavenging.

[0041] In this embodiment, the exhaust device 1 is located above the scavenging device 2. The exhaust device 1 is used to collect and accommodate the exhaust gas discharged from the exhaust valves of the main engine, and send it to the scavenging device 2 after the pressure fluctuation is stabilized. The length of the device 1 is no more than the length of the upper platform of the main engine, the width is no more than three times the bore of the main engine, and the installation height of the ex...

Embodiment 2

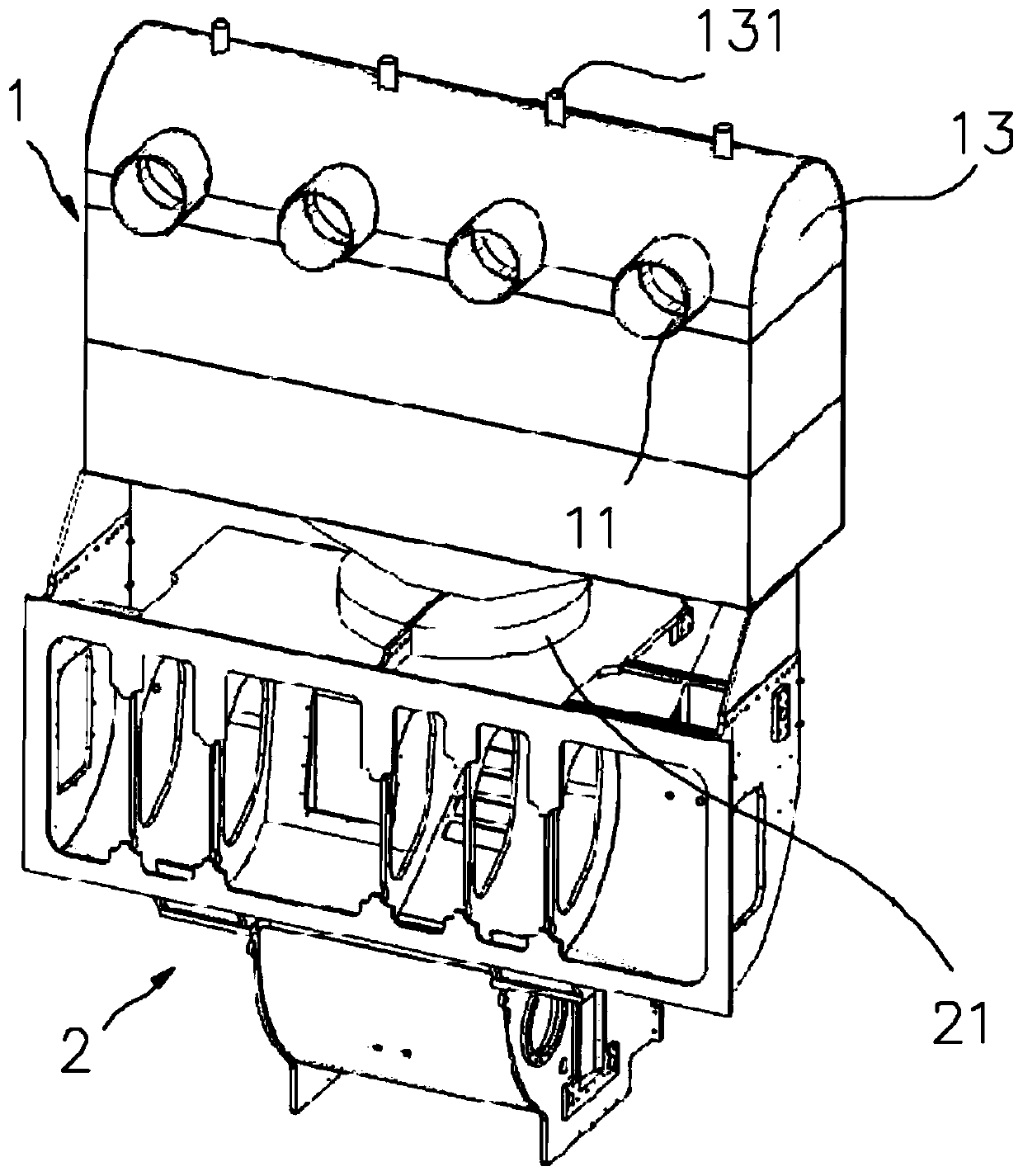

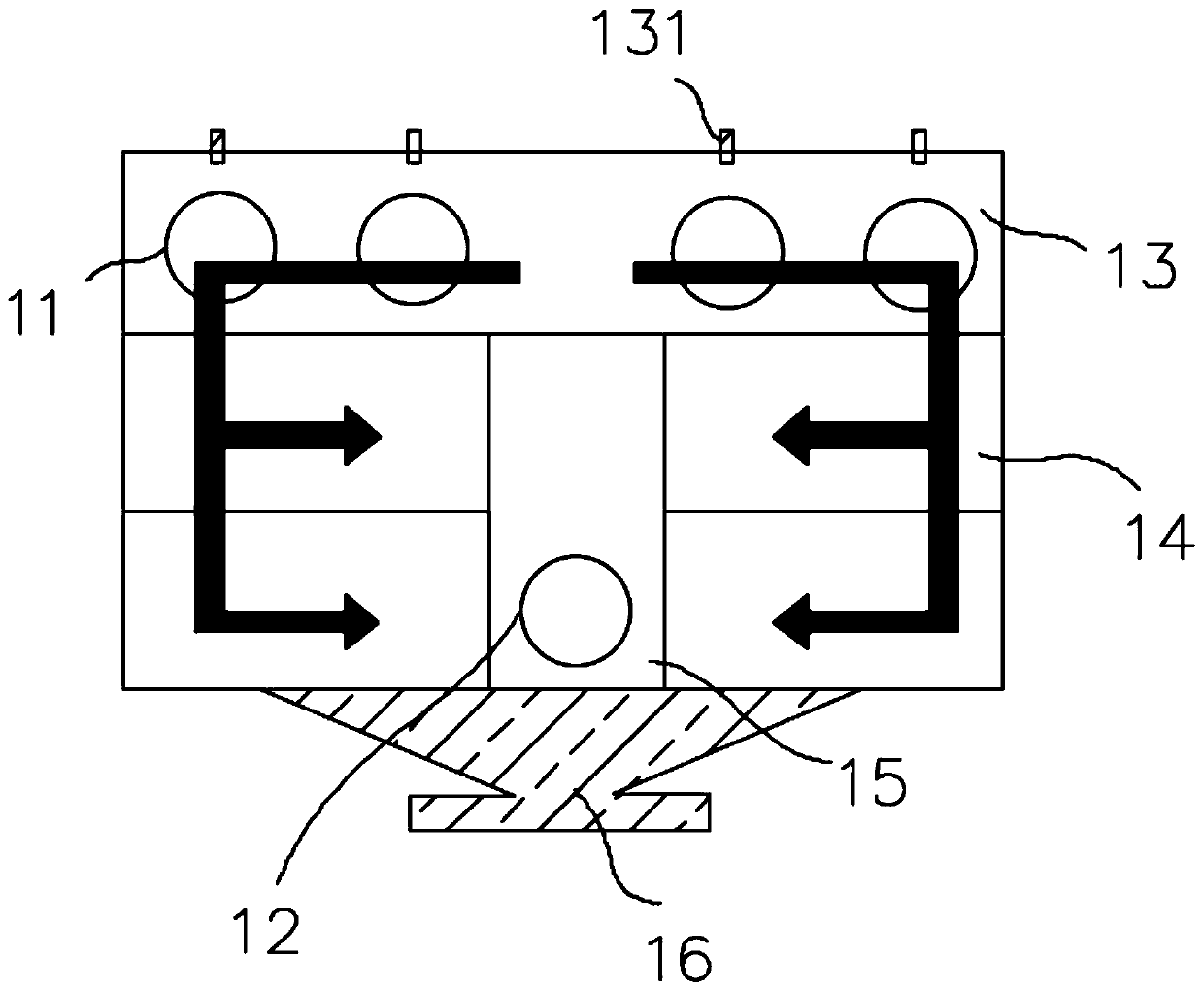

[0047] see Figure 2 ~ Figure 4 Another exhaust and scavenging system for a two-stroke diesel engine provided by the present invention includes an exhaust device 1 and a scavenging device 2, and both the exhaust device 1 and the scavenging device 2 are connected to the main engine of the two-stroke diesel engine.

[0048] It should be noted that the main engine includes a welded base, a frame and a casted cylinder block, and the scavenging method of the main engine is DC scavenging.

[0049] In this embodiment, the exhaust device 1 is located above the scavenging device 2, and the exhaust device 1 is provided with an exhaust gas post-processing unit. The exhaust device 1 is used to collect and process the exhaust gas discharged from each exhaust valve of the main engine to stabilize the pressure. After fluctuating, it is sent to the scavenging device 2. The length of the exhaust device 1 does not exceed the length of the upper platform of the main engine, the width does not ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com