Control method for realizing precontrol EGR system

A technology of recirculation system and exhaust gas recirculation valve, applied in exhaust gas recirculation, charging system, engine components, etc., can solve the problems of overshoot and oscillation, error, slow response of EGR system, etc., to improve transient response, Eliminates errors, reduces ringing and overshoot effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

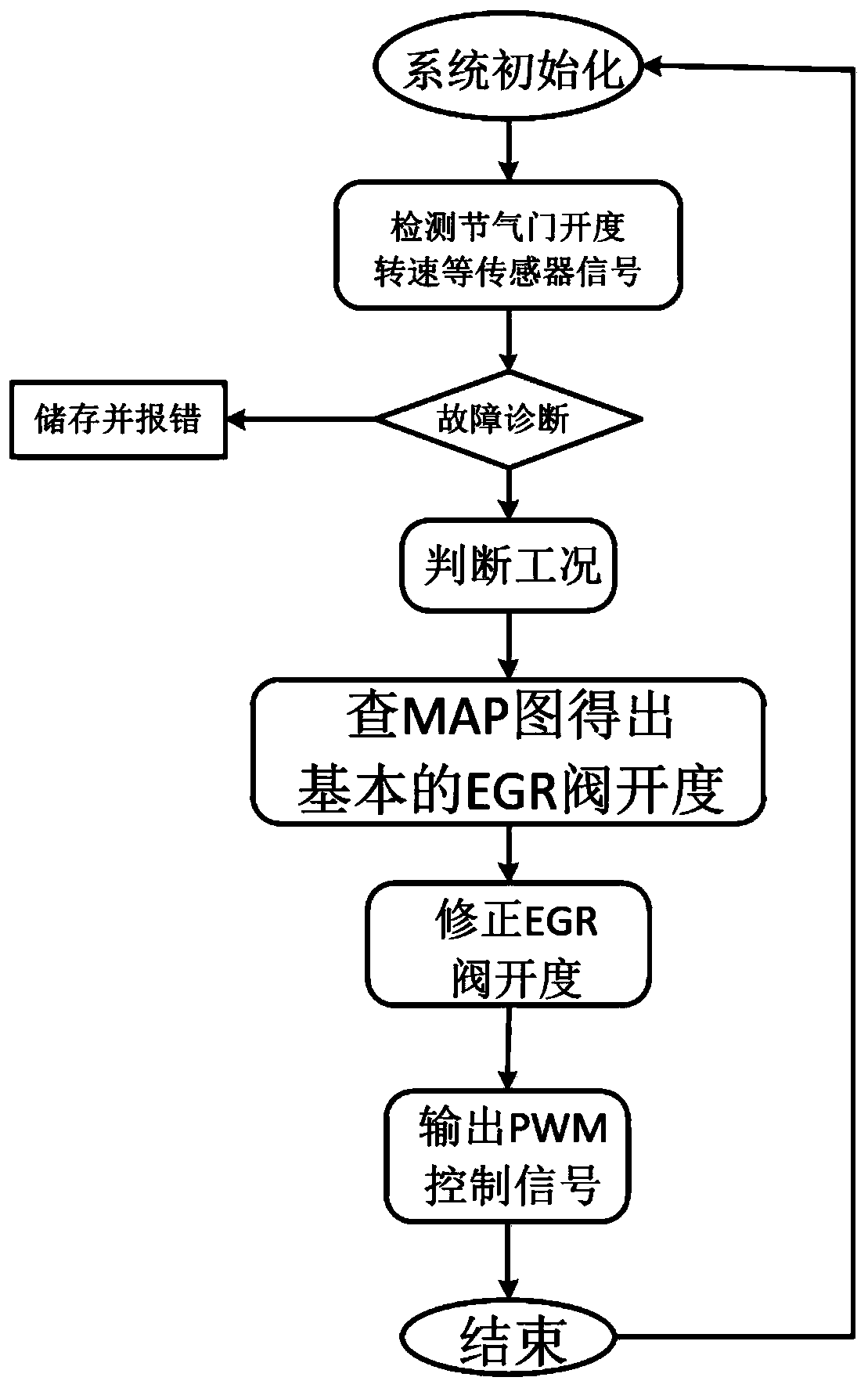

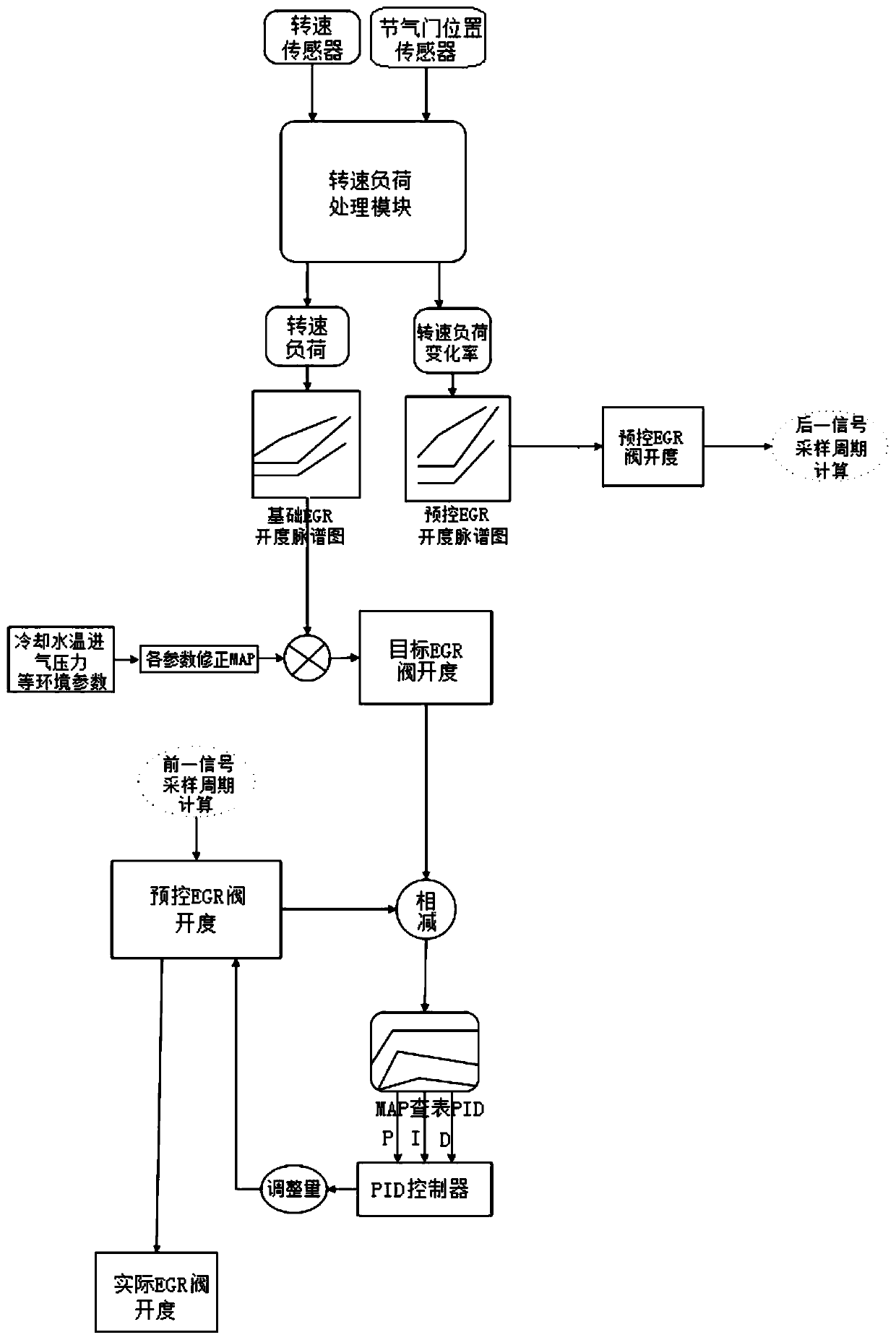

[0018] Such as image 3 The flow chart of the control method for realizing the pre-control exhaust gas recirculation system of the present invention is shown, including the following steps:

[0019] 1. The ECU control unit converts and processes the collected throttle position signal and engine speed signal into two signals: the first signal is the engine speed and load signal; the second signal is the engine speed and load change rate signal. There is a timing sequence when the two signals are sent, and the speed and load change rate signals are delayed by 5ms relative to the speed and load signals;

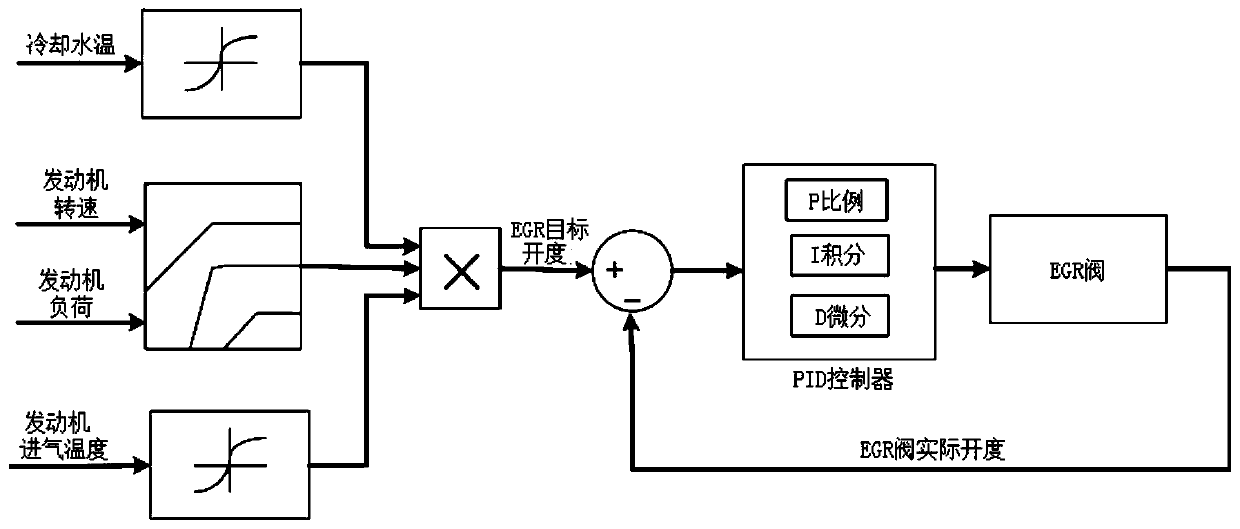

[0020] 2. The first signal The engine speed and load signals are used to judge the basic state of the engine. At the same time, the correction effect of the coolant temperature and the intake air temperature on the basic EGR valve opening is considered, and the calibrated EGR valve opening map is checked through the table. Figure, to determine the ideal EGR valve opening of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com