Low-noise low-energy-consumption refrigerating system and working method thereof

A refrigeration system and low-energy consumption technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problem that the amount of liquid in the pipeline at the outlet of the evaporator cannot be guaranteed, the heat exchange length between the return pipe and the capillary is limited, and the refrigerant The gas is prone to overheating and other problems, which can increase the difficulty of product processing, improve the cooling capacity and operating efficiency, and have obvious advantages in energy saving and emission reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

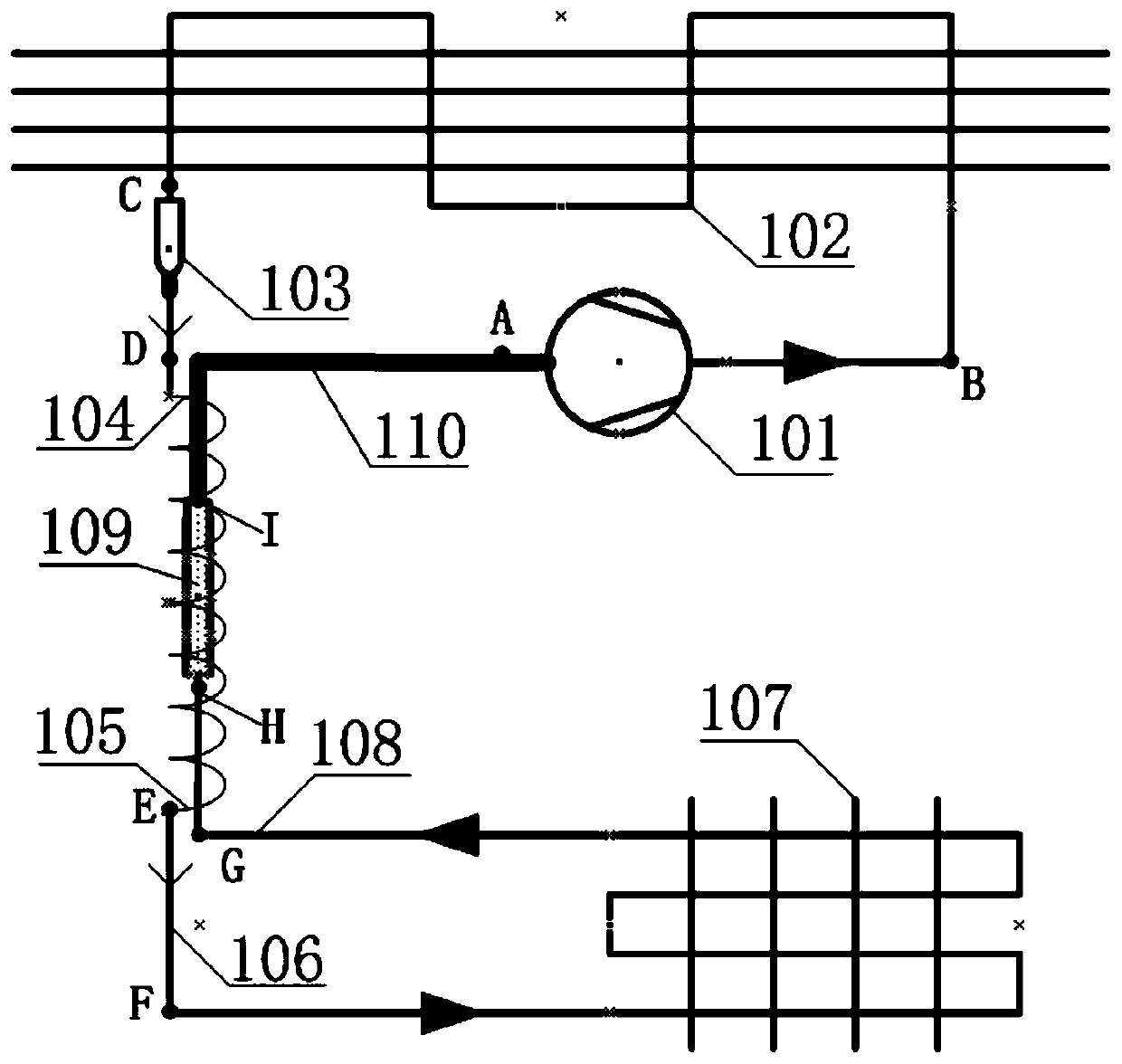

[0015] Such as figure 1 As shown, the present invention is a refrigeration system with low noise and low energy consumption. The outlet of the compressor 101 is connected to the inlet of the condenser 102, the outlet of the condenser 102 is connected to the inlet of the dry filter 103, and the outlet of the dry filter 103 is connected to the capillary inlet section 104. , the capillary outlet section 105 is connected to the evaporator inlet pipe 106, the evaporator inlet pipe 106 is connected to the evaporator 107, the evaporator 107 is connected to the evaporator outlet pipe 108, the evaporator outlet pipe 108 is connected to the inlet of the low pressure liquid reservoir 109, and the low pressure The outlet of the liquid reservoir 109 is connected with the inlet of the gas return pipe 110 . Among them, the outer wall surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com