Carpet with self-twisted loop pile and methods for making the same

A carpet and tufting technology, applied in the field of making the carpet, can solve the problem of insignificant durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

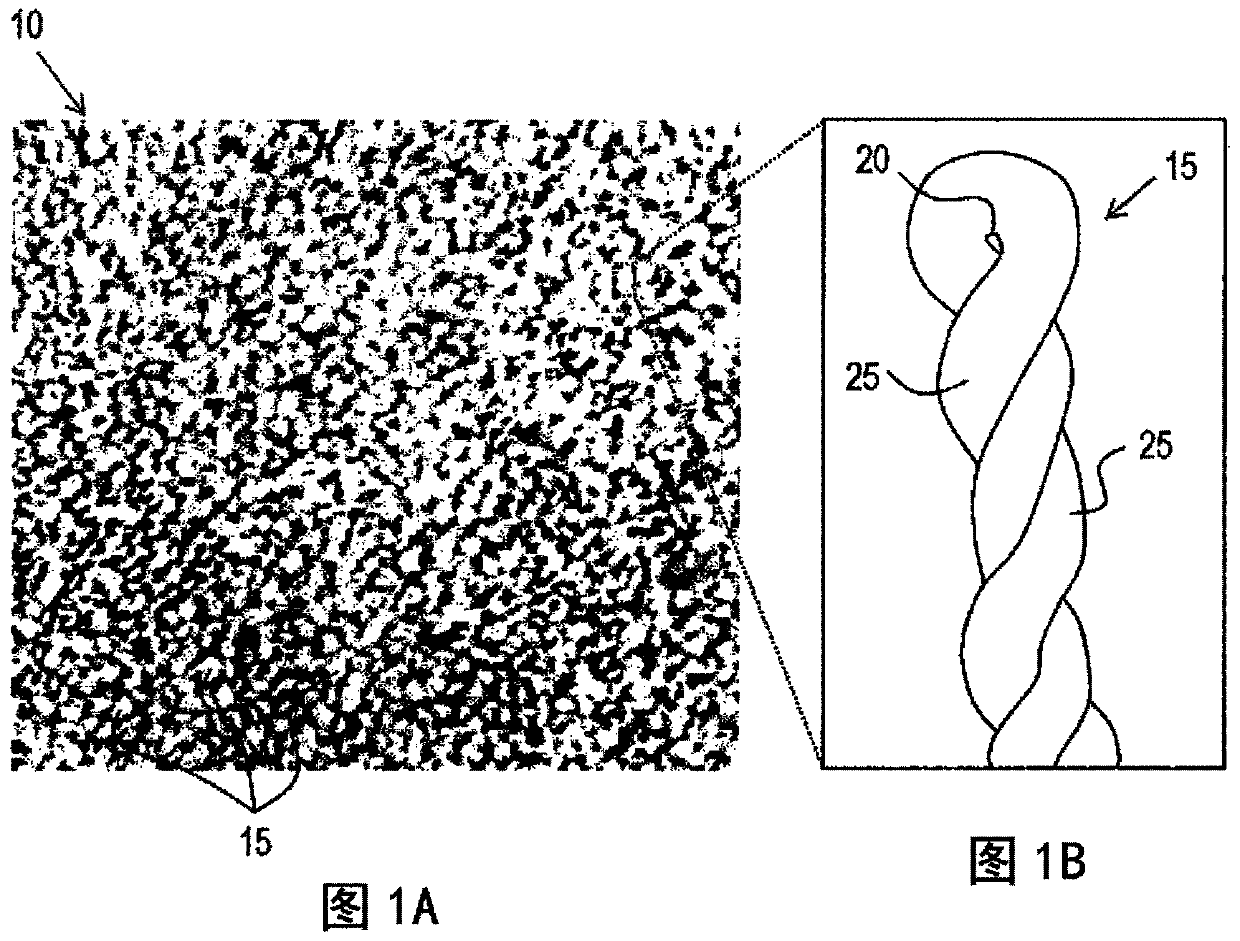

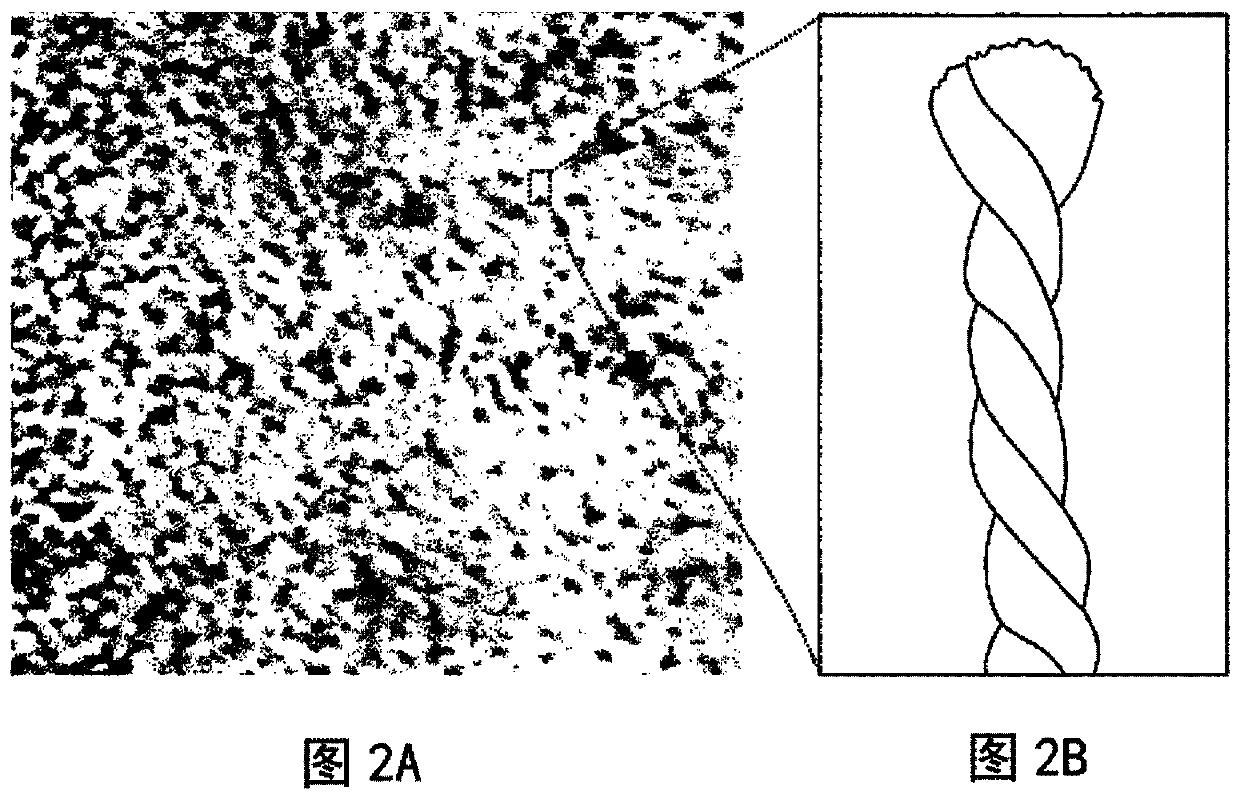

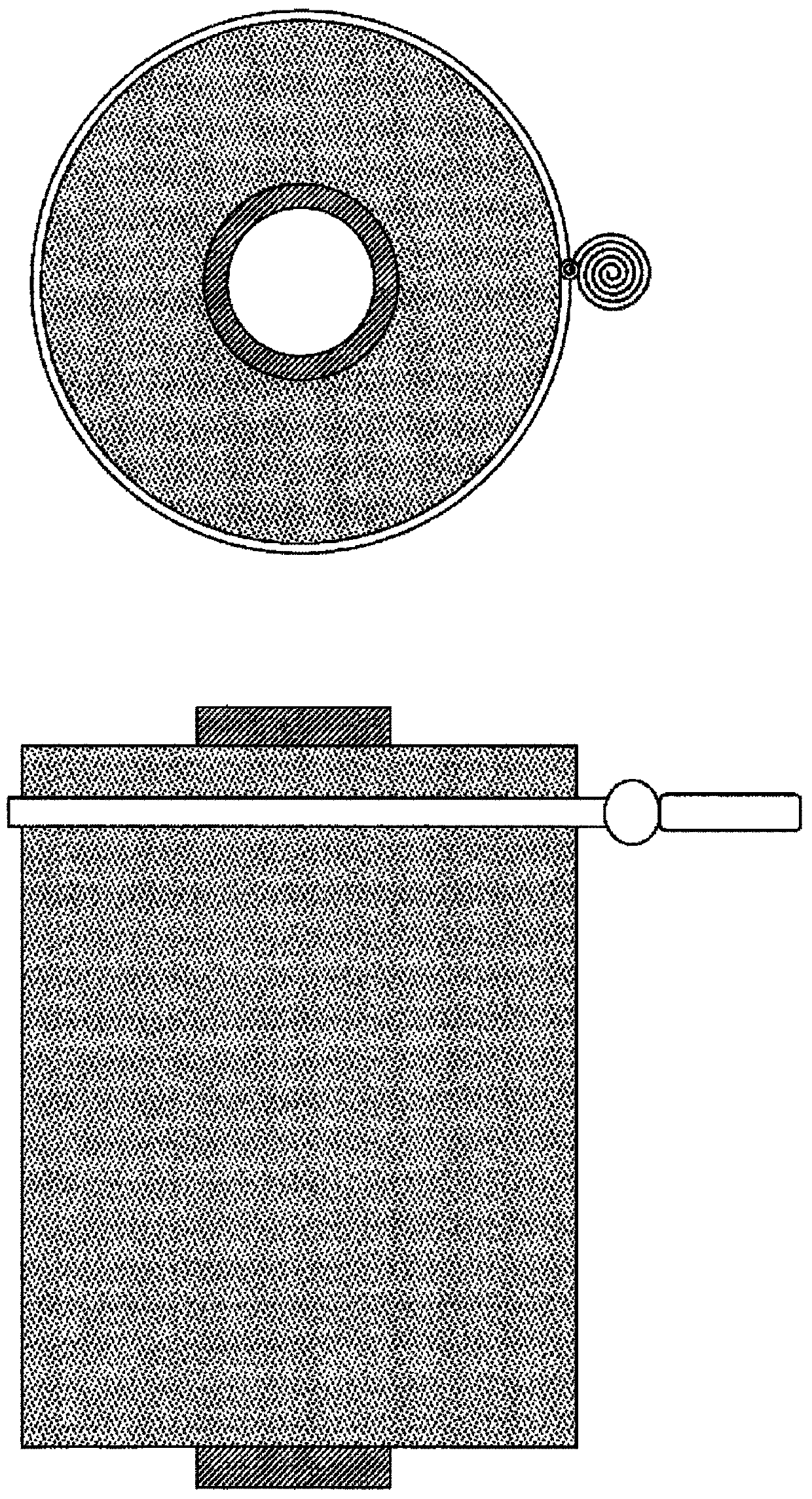

[0050] Example 1: Polyethylene Terephthalate (PET) Carpet

[0051] Polyethylene terephthalate (PET) BCF yarns having a nominal 1170 denier, 130 filaments, and trilobal cross-section were converted into standard cut pile carpet (referred to herein as "PET control carpet") ) and the carpet of the present disclosure (referred to herein as "PET carpet"). Heatset the twisted yarn in a Superba at 290°F by twisting two yarns together at 5.75 turns per inch (tpi), then tufted to 1 / 8 th Gauge, 45Oz / sq.yd. carpet with a pile height of 0.625” was used to make a PET control carpet. By twisting a single yarn at 8.9tpi and then tufting it to 1 / 16 th Gauge, 45Oz / sq.yd. carpet, wherein pile height is 0.625 ", to make the PET carpet of the present disclosure. Around has spiral groove (it has pitch of 1 / 2 ", depth of 1 / 4 " and 5 / 16 A 2" tension bar with a width of 2" was wrapped around the twisted single-ply yarn (2.5 turns) to provide sufficient tension to remove tangles from the yarn. The...

Embodiment 2

[0052] Example 2: Nylon 66 carpet

[0053] Nylon 66BCF yarn having a nominal 997 denier, 115 filaments, and a trilobal cross-section was converted into a standard cut pile carpet (referred to herein as "Nylon 66 Control Carpet-1") and a carpet of the present disclosure (herein Referred to as "Nylon 66 Carpet-1"). Heatset the twisted yarn in a Superba at 265°F by twisting two yarns together at 5.75tpi, then tufted to 1 / 8 th Gauge, 45Oz / sq.yd. Carpet with a pile height of 0.625" was used to make Nylon 66 Control Carpet-1. By twisting a single yarn at 8.9 tpi and then tufting it to 1 / 16 th Gauge, 45Oz / sq.yd. carpet, wherein pile height is 0.625 ", to make nylon 66 carpet-1 of the present disclosure. Around has spiral groove (it has pitch of 1 / 2 ", depth of 1 / 4 " and 5 / 16" width) around the twisted single-ply yarn (2.5 turns) to provide sufficient tension to remove tangles from the yarn. The durability of the carpet was tested using the standard test method above. In Durabili...

Embodiment 3

[0054] Example 3: Nylon 66 carpet

[0055] Nylon 66BCF yarn having a nominal 800 denier, 80 filaments and a trilobal cross-section was converted into a standard cut pile carpet (referred to herein as "Nylon 66 Control Carpet-2") and a carpet of the present disclosure (herein Referred to as "Nylon 66 Carpet-2"). Heatset the twisted yarn in a Superba at 265°F by twisting two yarns together at 5.75tpi, then tufted to 1 / 8 th Gauge, 45Oz / sq.yd. carpet with a pile height of 0.625", to make Nylon 66 Control Carpet-2. By twisting a single yarn at 7.5tpi and then tufting it to 1 / 16 th gauge, 45 Oz / sq.yd. carpet with a pile height of 0.625", to make Nylon 66 Carpet-2 of the present disclosure. Place a plastic bag around the package, leaving an opening at the front for yarn exit. Use A hysteresis-type tensioner was used to provide sufficient tension to remove tangles from the yarn. The durability of the carpet was tested using the standard test method described above. The durability ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com