Preparation method of nickel plated aluminum powder

A nickel-plated aluminum and aluminum powder technology, applied in the direction of liquid chemical plating, coating, metal material coating process, etc., can solve the problems of high cost of aluminum powder silver plating, difficult plating, unstable plating solution, etc. Achieve the effect of good nickel magnetic permeability, strong binding force, and prevention of re-formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

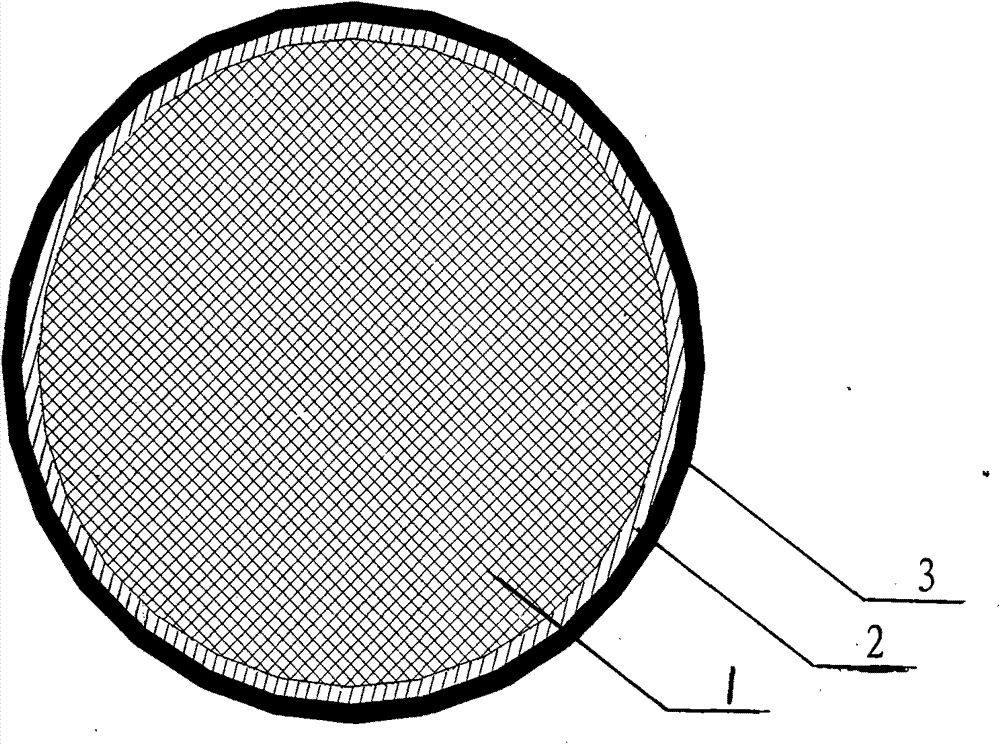

[0036] a. Alkali washing: Put the spherical aluminum powder of aluminum particle 1 with a particle size of 200 mesh and a spherical shape into an ammonium hydroxide solution with a volume concentration of 1000mL / L, stir for 0.5min, and then wash it with water;

[0037] b. Pretreatment: first configure the pretreatment solution according to the ratio of sodium citrate:ammonia water=3g:300mL, then add the aluminum powder washed with alkali in step a into the pretreatment solution, and stir for 5s; or

[0038] Add the alkali-washed aluminum powder in step a to 15g / L sodium fluoride, and stir for 5s;

[0039] c. Pre-plating: first configure the pre-plating solution according to the ratio of sodium citrate: ammonia water: potassium sodium tartrate: potassium pyrophosphate = 3g: 300mL: 0.1g: 10g, then add the pre-treated aluminum powder in step b to the pre-plating solution, adjust the pH to 9 with sodium hydroxide or ammonia water, stir for 60 seconds and wash with water;

[0040]...

Embodiment 2

[0043] a. Alkali washing: Put the spherical aluminum powder with a particle size of 1500 mesh in aluminum particle 1 into an ammonium hydroxide solution with a volume concentration of 50 mL / L, stir for 5 minutes, and then wash it with water;

[0044] b. Pretreatment: first configure the pretreatment solution according to the ratio of sodium citrate:ammonia water=20g:100mL, then add the aluminum powder washed with alkali in step a into the pretreatment solution, and stir for 60s; or

[0045] Add the alkali-washed aluminum powder in step a to 0.5g / L sodium fluoride, and stir for 60s;

[0046] c. Pre-plating: first configure the pre-plating solution according to the ratio of sodium citrate: ammonia water: potassium sodium tartrate: potassium pyrophosphate = 20g: 100mL: 5g: 0.2g, then add the pre-treated aluminum powder in step b to the pre-plating solution, adjust the pH to 13 with sodium hydroxide or ammonia water, stir for 5 seconds, and wash with water;

[0047] d. electroles...

Embodiment 3

[0050] a. Alkali washing: Put the spherical aluminum powder with a particle size of 1000 meshes into the ammonium hydroxide solution with a volume concentration of 500mL / L, stir for 3 minutes, and then wash it with water;

[0051]b. Pretreatment: first configure the pretreatment solution according to the ratio of sodium citrate:ammonia water=12g:200mL, then add the aluminum powder washed by alkali in step a into the pretreatment solution, and stir for 30s; or

[0052] Add the alkali-washed aluminum powder in step a to 10g / L sodium fluoride, and stir for 30s;

[0053] c. Pre-plating: first configure the pre-plating solution according to the ratio of sodium citrate: ammonia water: potassium sodium tartrate: potassium pyrophosphate = 10g: 200mL: 3g: 5g, and then add the pretreated aluminum powder in step b to the pre-plating solution , adjust the pH to 11 with sodium hydroxide or ammonia water, stir for 30 seconds and wash with water;

[0054] d. electroless plating: the c step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com