Preparation of polyamides by hydrolytic polymerization, postpolymerization and subsequent extraction

A polyamide, post-polymerization technology, applied in the direction of one-component polyamide rayon, etc., can solve the problems of increasing the viscosity of polyamide polyamide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

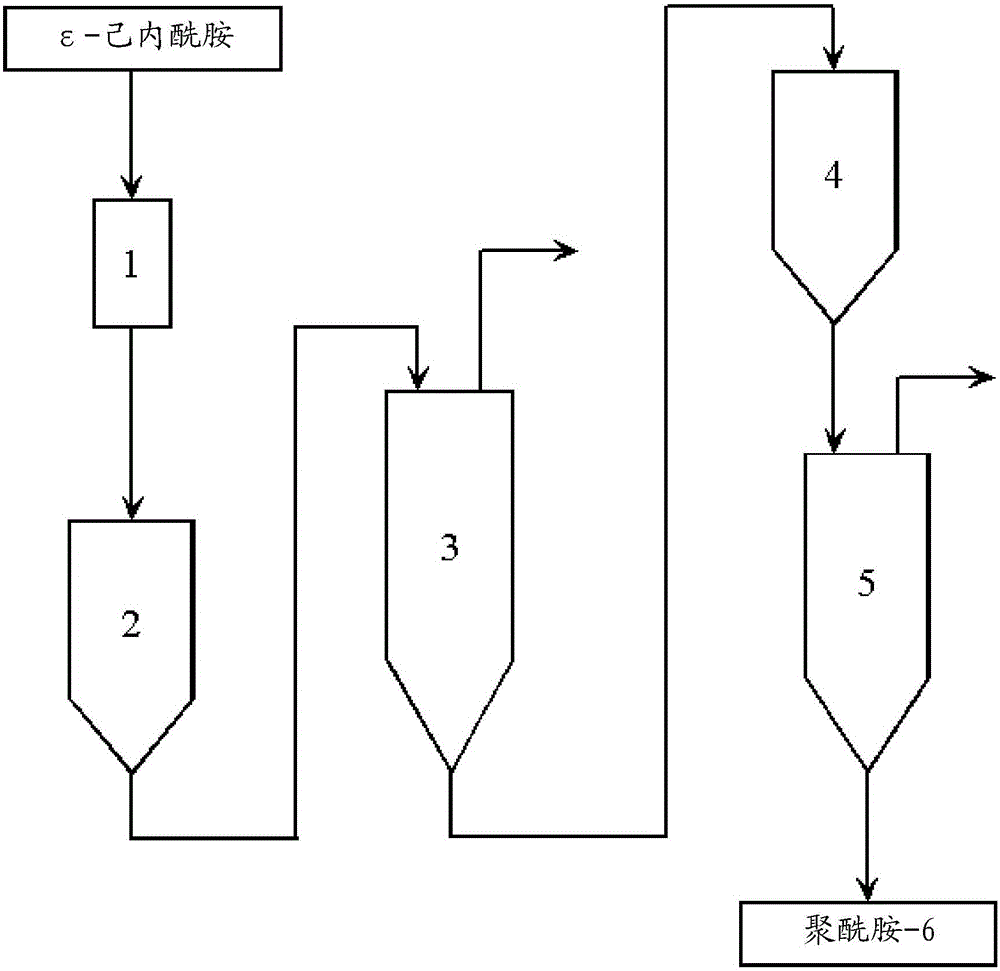

preparation example Construction

[0049] In the preparation of polyamides, one or more chain transfer agents can be used, such as aliphatic amines or diamines, such as triacetonediamine; or monocarboxylic or dicarboxylic acids, such as propionic acid and acetic acid; or aromatic Carboxylic acids such as benzoic acid or terephthalic acid.

[0050] Step b)

[0051] The conversion of the monomer mixture provided in step a) in the hydrolytic polymerization in step b) can be carried out by standard methods known to the person skilled in the art. Such methods are described, for example, in Kunststoff Handbuch, 3 / 4 Technische Thermoplaste: Polyamide, Carl Hanser Verlag, 1998, Munich, pp. 42-47 and 65-70. The disclosure content thereof is hereby incorporated by reference in its entirety into this specification.

[0052] Preferably, in step b), the hydrolytic polymerization is carried out by ring-opening the lactam under the action of water. This includes, for example, the at least partial cleaving of lactams to g...

Embodiment 1-5

[0119] The starting material is a pelletized polyamide-6 intermediate available on an industrial scale obtained from the polyamide-6 production process after pelletization after one-stage melt polymerization in a VK tube . This intermediate has a viscosity of 139 ml / g, a caprolactam content of 12.84% and a dimer content of 0.37%.

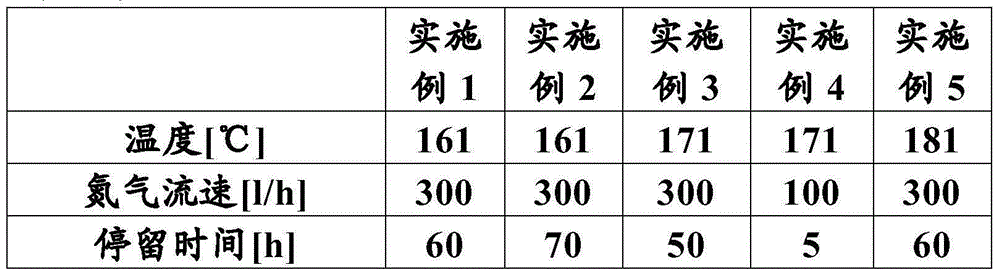

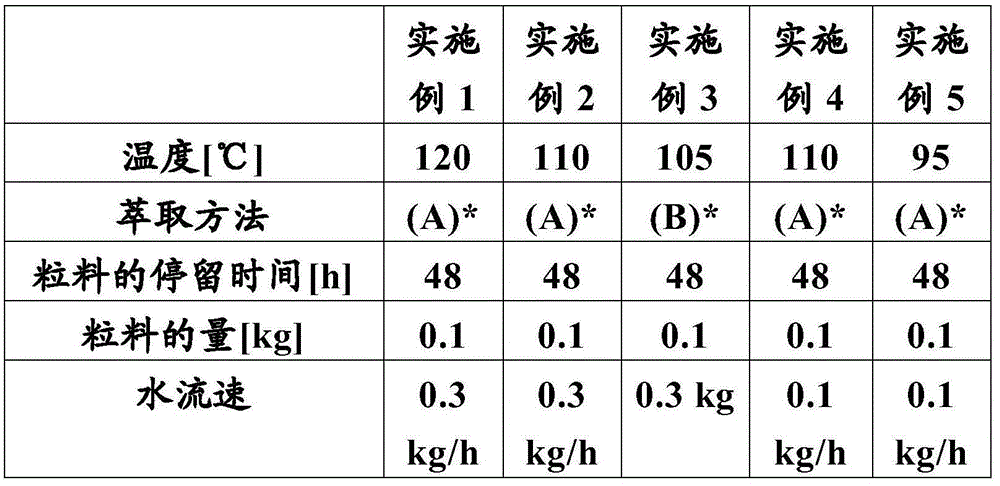

[0120] For solid phase postpolymerization, 100 g of pellets were heat treated in a solid phase apparatus. The solid-phase device consists of a glass tube with a frit base, which is heated by means of an outer jacket. The pellets were introduced into a preheated glass tube and hot nitrogen was flowed through for a specified dwell time. After the residence time, the pellets were removed and transferred to an extraction unit. The extraction apparatus used was a 2L tank. This was done by initially charging deionized water and heating it to 90°C. Addition of the pellets is followed by heating to extraction temperature. The extraction is carried out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com