System for preparing organic fertilizer from wet garbage

An organic fertilizer and garbage technology, applied in the field of food waste treatment equipment, can solve the problems of no air humidity adjustment, affecting degradation efficiency, unfavorable microorganism survival, etc., and achieve the effect of improving activity and degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

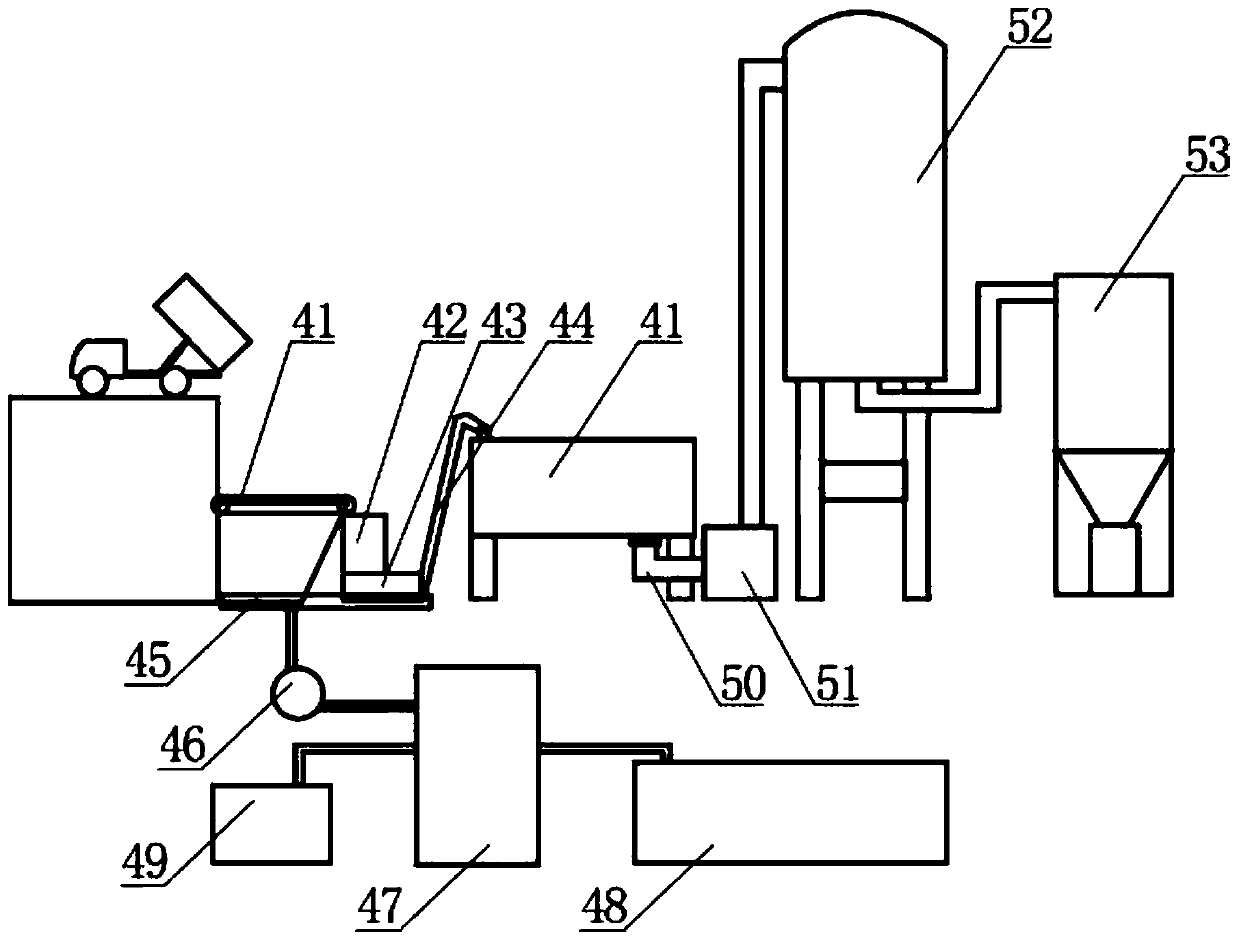

[0031] like figure 1 As shown, the system for producing organic fertilizer from wet garbage includes a garbage sorter 41, a pulverizer 42, a squeeze dehydrator 43, a garbage lifting device 44, a liquid collector 45, a liquid pump 46, an oil-water separator 47, and an oil collector. Container 48, sewage processor 49, degradation machine 25, heat exchanger 26, deodorization device 27, closed degradation material conveyor 50, degradation material concentrator 51, powder dryer 52, bagging machine 53, garbage sorter 41 is used to sort out the metal materials in the food waste. The sorted food waste is crushed by the shredder 42 and sent to the extrusion dehyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com