Precast concrete waterproof structure

A prefabricated concrete and structure technology, which is applied in building structures, building components, building insulation materials, etc., can solve the problems of poor waterproof performance, difficult construction, and insufficient dimensional accuracy of the sill, and achieves improved waterproof level and low construction difficulty. , The effect of producing high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

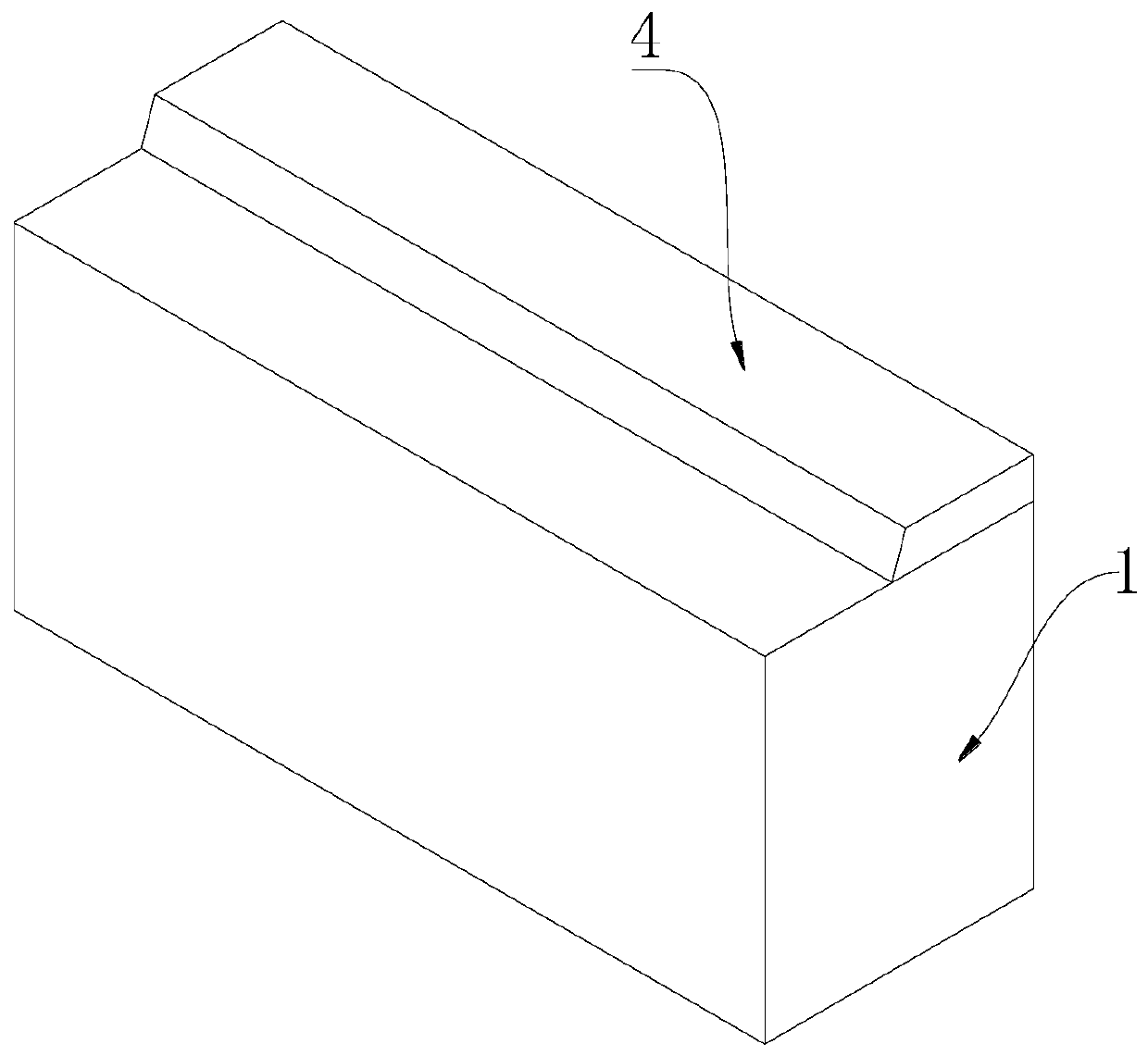

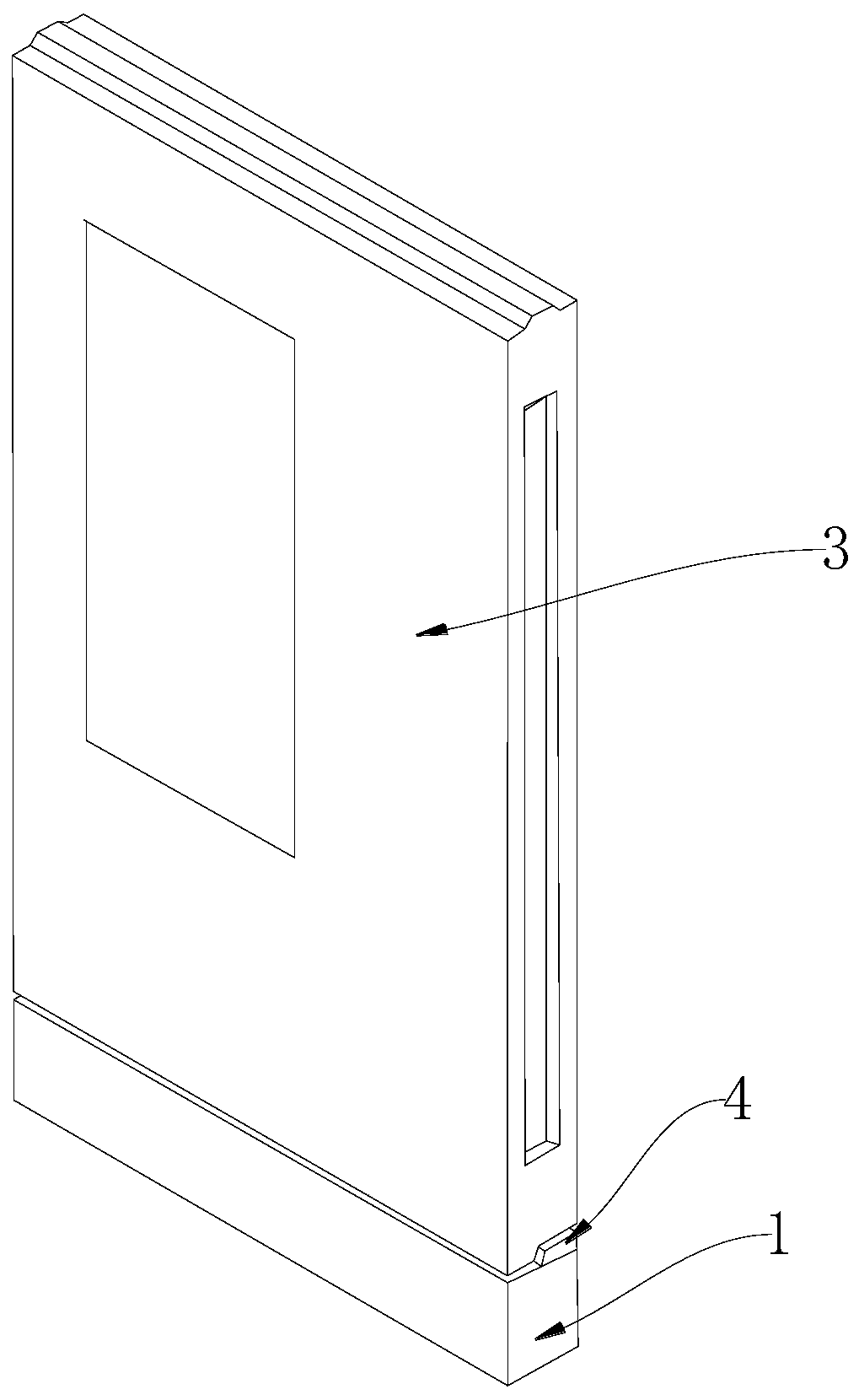

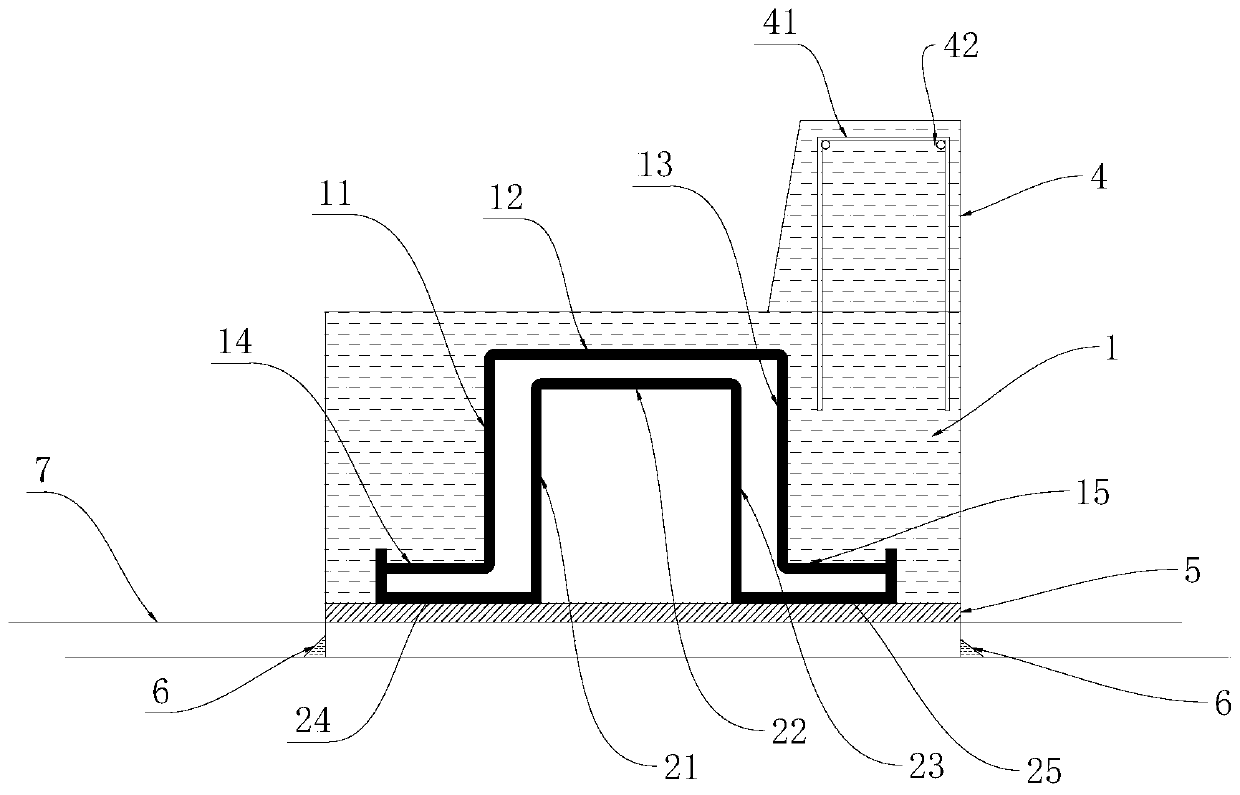

[0020] In order to express the present invention more clearly, the present invention will be further described below with reference to the accompanying drawings.

[0021] 5.2.1 of the "Technical Specification for Indoor Waterproof Engineering of Residential Buildings" JGJ298-2013 stipulates that: toilets, bathrooms, floors and floors should be provided with a waterproof layer, walls and ceilings should be provided with a moisture-proof layer, and the doorway should have measures to prevent the overflow of accumulated water; At the same time, 4.1.2 of the code stipulates that solvent-based waterproof coatings must not be used in residential indoor waterproofing projects; in the industry, measures such as waterproof ridges can generally be taken for buildings and floors with drainage.

[0022] The traditional cast-in-place method is used for the construction of the cast-in-place method. The cast-in-place method is usually used to make the waterproof cast-in-place after the floor slab ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com