Multi-objective optimization method for washing and selecting coal

A multi-objective optimization and objective technology, which is applied in the special application scenarios of coal mines and in the field of data processing, and can solve problems such as the inability to optimize products with large objectives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

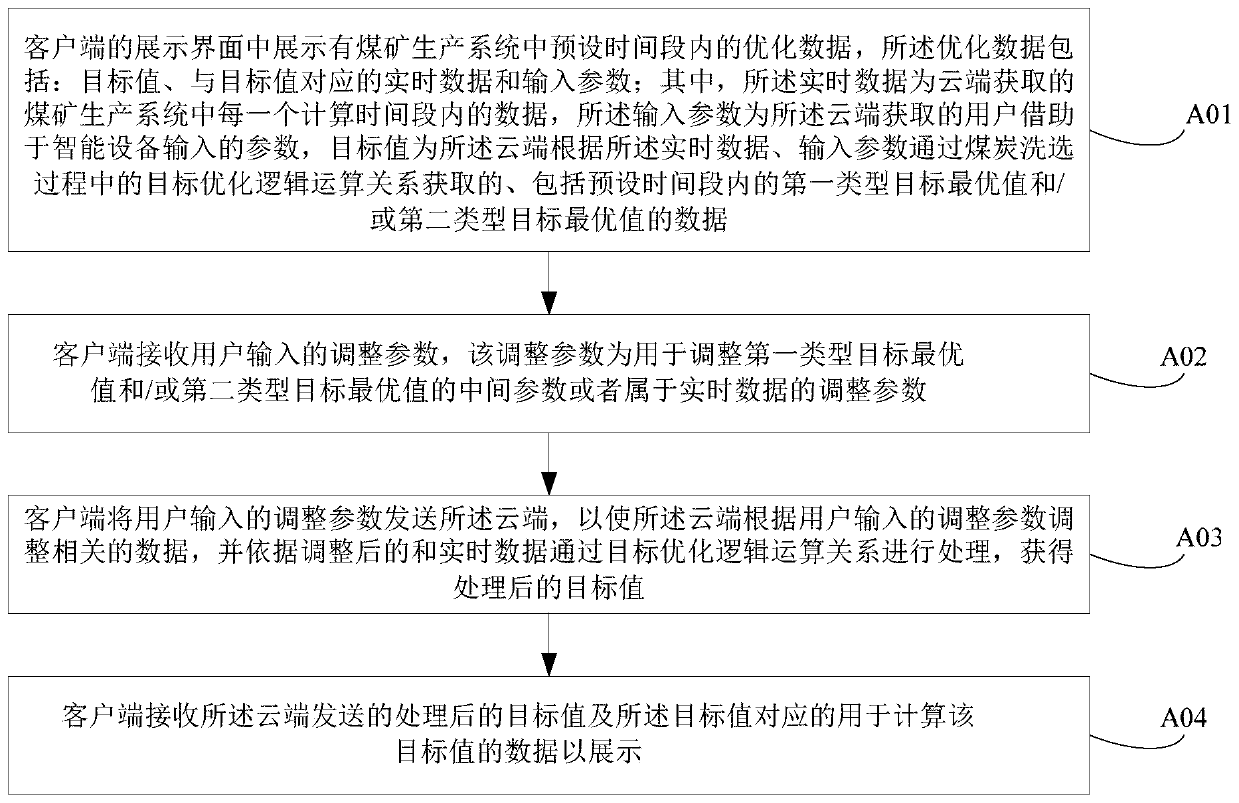

[0092] Such as figure 1 as shown, figure 1 It is a schematic flow chart of the multi-objective optimization method for coal washing and blending provided by an embodiment of the present invention. The execution subject of the method in this embodiment can be any terminal used to display the final target value. Specifically, the method includes the following step:

[0093] A01. The display interface of the client shows the optimization data within the preset time period in the coal mine production system. The optimization data includes: target value, real-time data corresponding to the target value and input parameters; wherein, the real-time data is cloud The data obtained in each calculation time period in the coal mine production system, the input parameters are the parameters input by the user through the smart device obtained by the cloud, and the target value is the cloud through the coal according to the real-time data and input parameters. The data acquired by the tar...

Embodiment 2

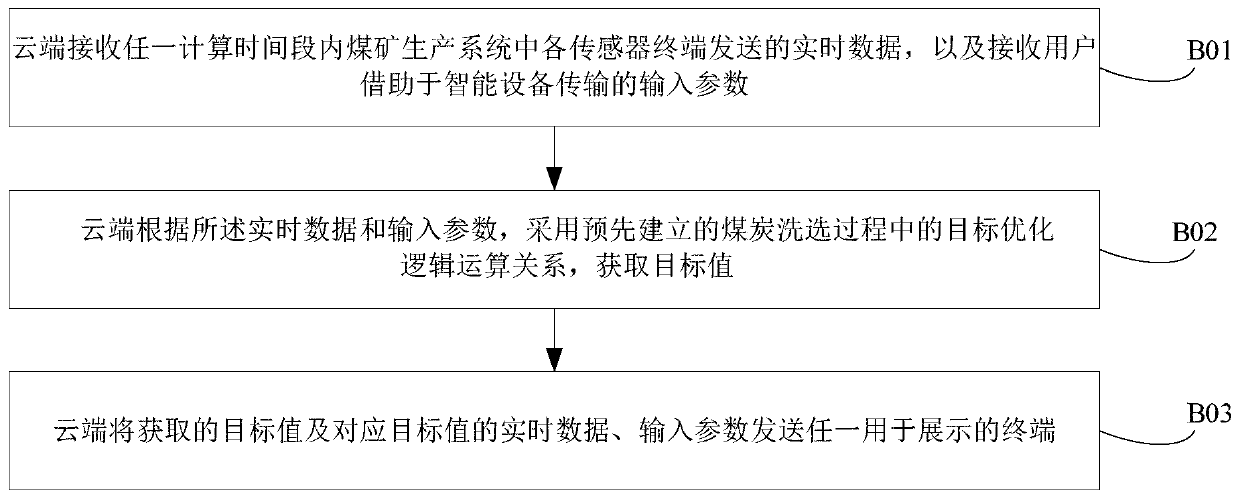

[0107] Such as figure 2 as shown, figure 2 It is a schematic flowchart of a multi-objective optimization method for coal washing and blending provided in another embodiment of the present invention. The execution subject of the method in this embodiment can be any cloud server. Specifically, the method includes the following steps:

[0108] B01. The cloud receives the real-time data sent by each sensor terminal in the coal mine production system within any calculation period, and receives the input parameters transmitted by the user with the help of smart devices.

[0109] For example, the real-time data in each calculation time period in this embodiment includes the following kinds of data: the real-time output of various coal products sent by means of the Internet of Things sensor devices installed in various positions of the coal washing plant , The inventory quantity of each coal product in the coal bunker, the coal quality test results of each coal product in the detec...

Embodiment 3

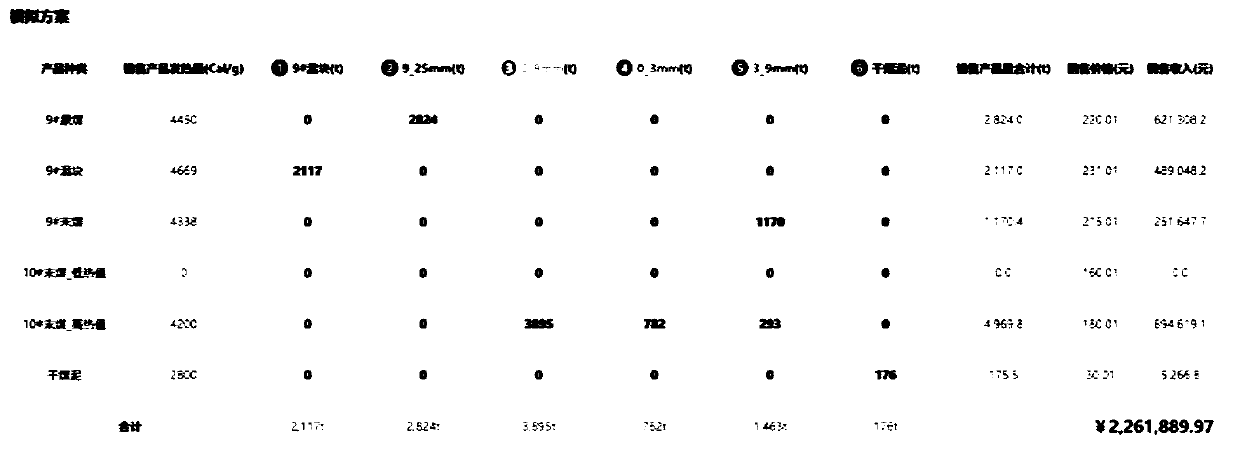

[0126] The embodiment of the present invention is realized in this way, step 1 data acquisition: collect the real-time output of each coal type product after the processing of the on-site washing plant through the Internet of Things box, and the real-time inventory of each coal type product in the coal bunker, and pass the data through the router gateway Transfer to the cloud for storage and data cleaning; collect the real-time coal quality test results of various coal products on site, the real-time sales guidance price of sales products (after coal blending is completed), coal quality requirements and sales demand through the mobile terminal, and the data is written into records Stored in the cloud; step 2 model results: the model inputs the output of production products, the sales volume of sales products, the calorific value of sales products, the price of sales products, the ratio of sales products, and the calorific value of production products. Ratio is used as a constra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com