Visual petroleum drilling platform risk analysis system

An oil drilling platform and risk analysis technology, applied in the direction of instruments, data processing applications, resources, etc., can solve problems such as insufficient division, insufficient operator station guidance, and insufficient risk category identification, achieving easy understanding and cost-effectiveness. Excellent and beneficial effect on risk management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

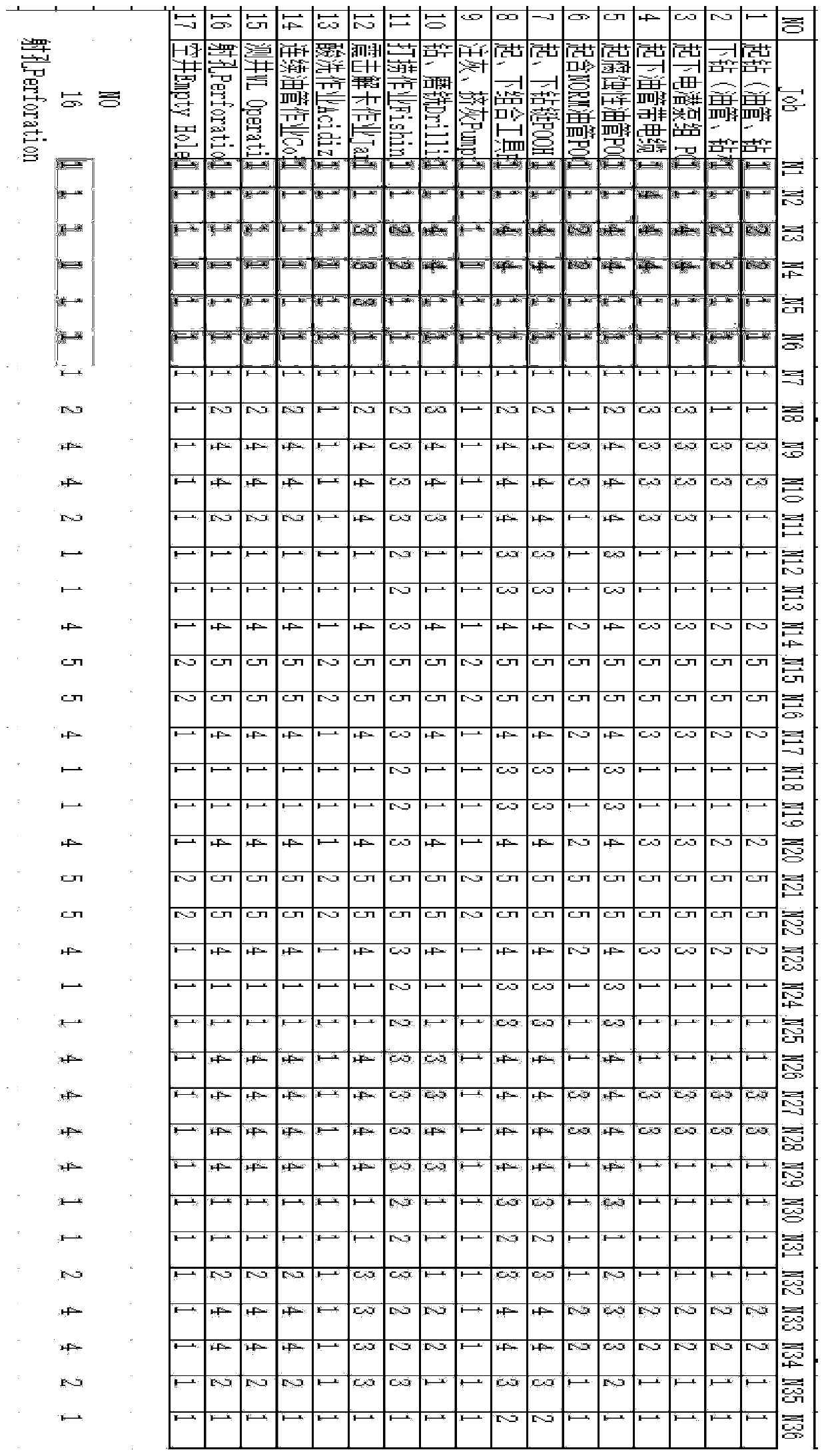

[0049] Embodiment 1: A visual oil drilling platform risk analysis system is constructed according to the following steps:

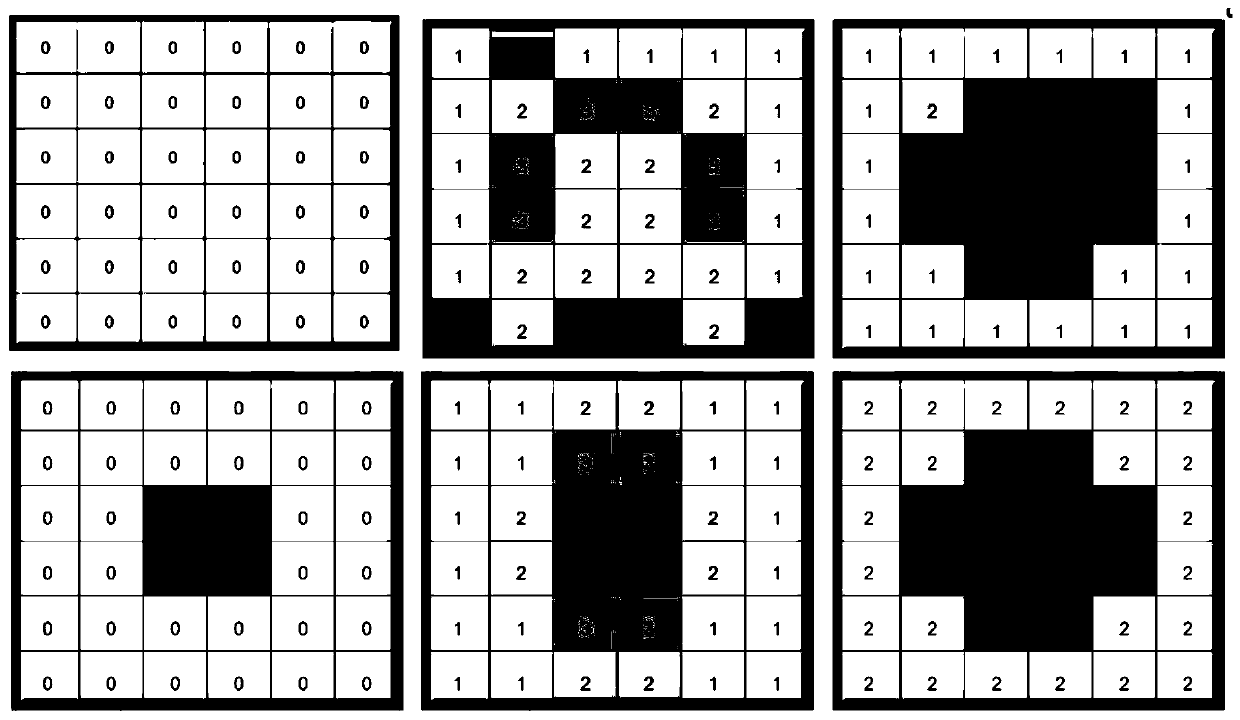

[0050] (1) Based on past accident cases and combined with on-site operating conditions, the risks that may occur on the drill floor surface are divided into six categories, namely: falling objects from height, object impact, falling, high pressure, harmful gas, and physical and chemical hazards;

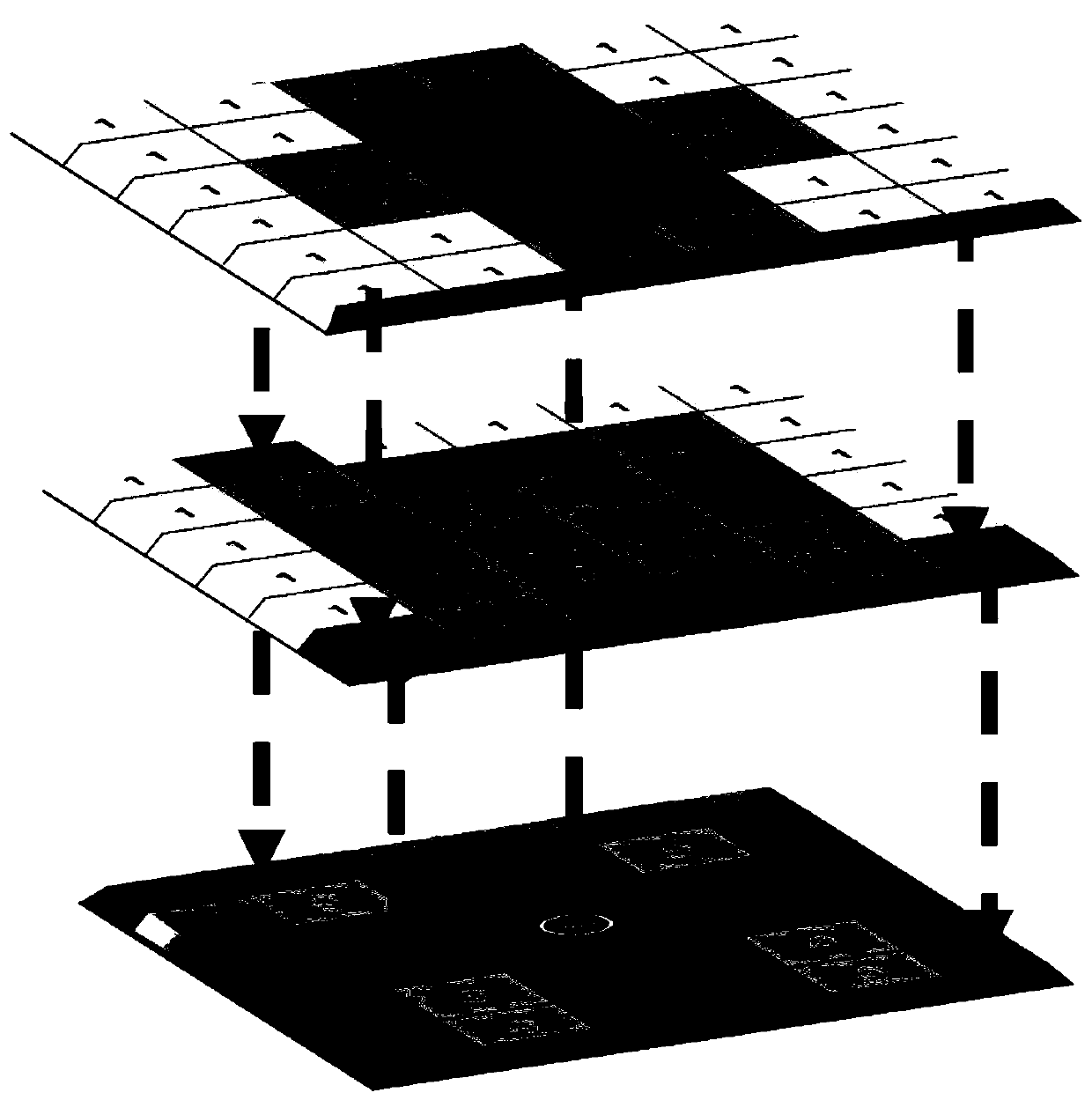

[0051] (2) According to the actual size of the drilling platform, according to the average station position and activity range of each person, make a matrix grid plan with a unit of 1m*1m square (such as Figure 4 shown);

[0052] (3) According to the risk value calculation formula R=R 0 +R n Calculate the total value at risk, where R is the total value at risk, and R 0 is the statistical risk value, R n is the weighted value at risk;

[0053] The R 0 =L×E, the L is the possibility of the accident, the E is the impact of the accident, calculate R after ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com