Friction nano generator and self-driving strain sensor and application thereof

A nanogenerator and strain sensor technology, applied in the field of sensing, can solve the problems of limiting the service life of sensors, energy consumption, environmental pollution, etc., and achieve the effects of good cycle performance, long life and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0059] In the first exemplary embodiment of the present disclosure, a triboelectric nanogenerator is provided, and the triboelectric nanogenerator of this embodiment can be used as a self-driving strain sensor.

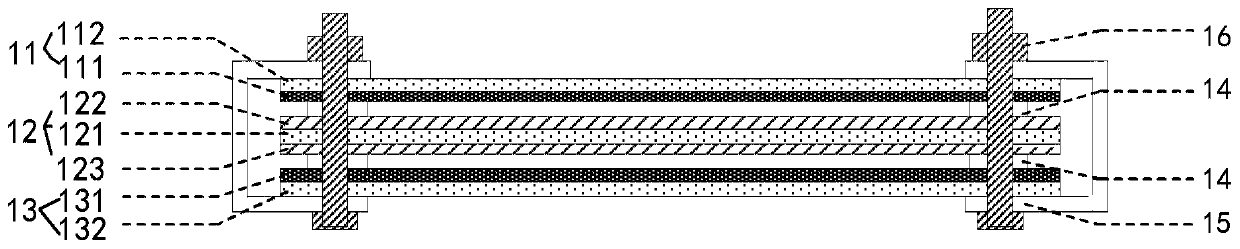

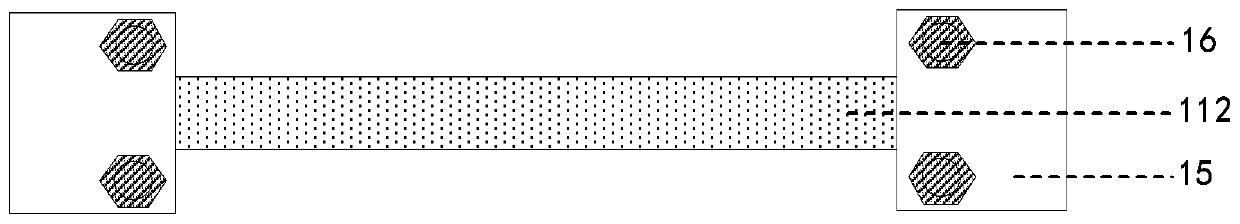

[0060] figure 1 It is a front view structural schematic diagram of a triboelectric nanogenerator according to an embodiment of the present disclosure. figure 2 For such figure 1 Schematic diagram of the top view structure of the triboelectric nanogenerator shown.

[0061] refer to figure 1 and figure 2 As shown, the triboelectric nanogenerator of the present disclosure includes: a conductive friction structure comprising a conductive friction layer; a friction structure spaced apart from the conductive friction structure, the friction structure comprising a dielectric friction layer, and the dielectric friction layer Set opposite to the conductive friction layer; wherein, under the action of the first external force, the conductive friction layer contacts and se...

no. 2 example

[0103] In a second exemplary embodiment of the present disclosure, a triboelectric nanogenerator is provided. Compared with the first embodiment, the triboelectric nanogenerator of this embodiment is a triboelectric nanogenerator in the form of two electrodes in a contact-separation mode.

[0104] Figure 11 It is a schematic structural diagram of an asymmetric contact-separation mode bi-electrode mode triboelectric nanogenerator according to an embodiment of the present disclosure.

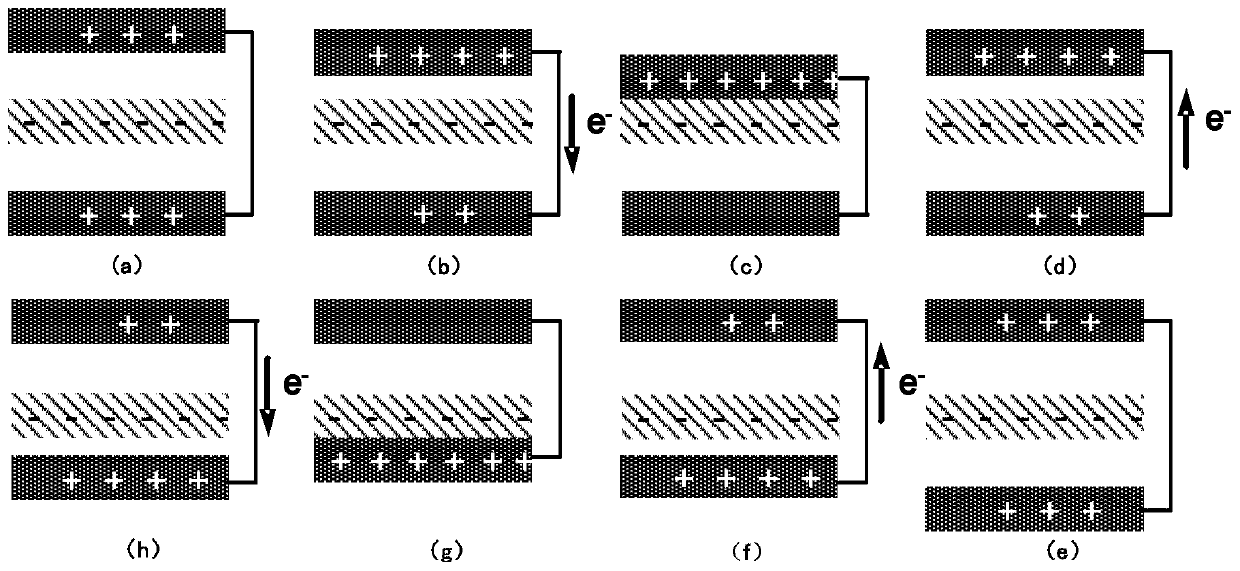

[0105] In this example, refer to Figure 11 As shown, the triboelectric nanogenerator is an asymmetric contact-separation mode double-electrode generator, and the conductive friction layer 111 and the dielectric friction layer 122 are respectively used as two electrode output ends of the generator.

[0106] In this embodiment, the triboelectric nanogenerator in this form is similar to the generator in the double-electrode form, and can be spaced and fixed in the form of a spacer layer and a sup...

no. 3 example

[0111] In a third exemplary embodiment of the present disclosure, a self-driven strain sensor is provided, including any triboelectric nanogenerator mentioned in the present disclosure.

[0112] In the self-driven strain sensor, the conductive friction structure of the triboelectric nanogenerator is used as the strain sensing unit, the second external force is applied to the conductive friction structure to generate strain, and the first external force is applied to the friction structure and the conductive friction structure at the same time function, making the contact-separation between the conductive friction layer and the dielectric friction layer, so that the resistance of the conductive friction layer changes due to the strain, and the electrical resistance of the conductive friction layer and the dielectric friction layer At least one of contact area, contact separation frequency, and amplitude parameters is varied to produce an electrical output indicative of said stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com