Method for tempering glass sheets

A glass plate and glass technology, applied in the tempering of glass, glass manufacturing equipment, manufacturing tools, etc., can solve the problems that the rear edge of the glass has not been initially cooled, and the kink problem of the rear end edge has not been disclosed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

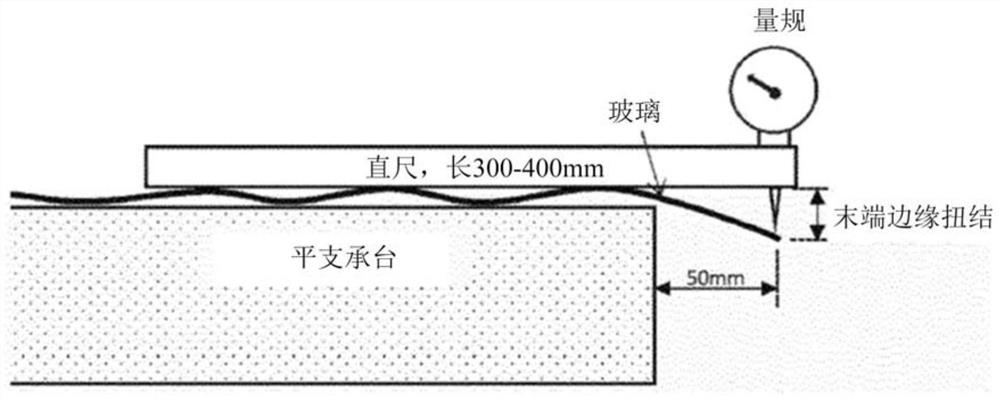

[0038] The apparatus consists of furnace 1 and quenching unit 2, which are in accordance with Figure 4 The order of the glass plate is continuous in the direction of travel. Furnace 1 is usually provided with a horizontal roller 5 or an air support table and its conveying element. These make up the conveyor tracks for the glass panels. During the heating cycle, the glass plate G to be heated is continuously driven in one direction or back and forth in the furnace at a constant speed. After heating to the tempering temperature, the glass plate enters the quenching unit 2 from furnace 1 at a transfer rate typically higher than the velocity of the glass in furnace 1. Typically, the transfer speed is 200-800mm / s.

[0039] as Figure 2 As shown, the quenching unit 2 is typically provided with a horizontal roller 5 and a cooling air seal 3 located above and below the roller. When furnace 1 is an air support surface, the roller 5 or air support table and its delivery element in the quench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com