Tobacco sheet slurry preparation method and millstone structures

A technology for tobacco sheet and pulp, which is applied to pulp beating method, pulp beating/refining method, tobacco and other directions, can solve the problems of over-grinding, some not being ground, affecting the quality of tobacco sheet, uneven thickness of tobacco stems, etc. , to reduce the energy consumption of papermaking, improve the effect of fiber removal, and save the power consumption of fiber removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

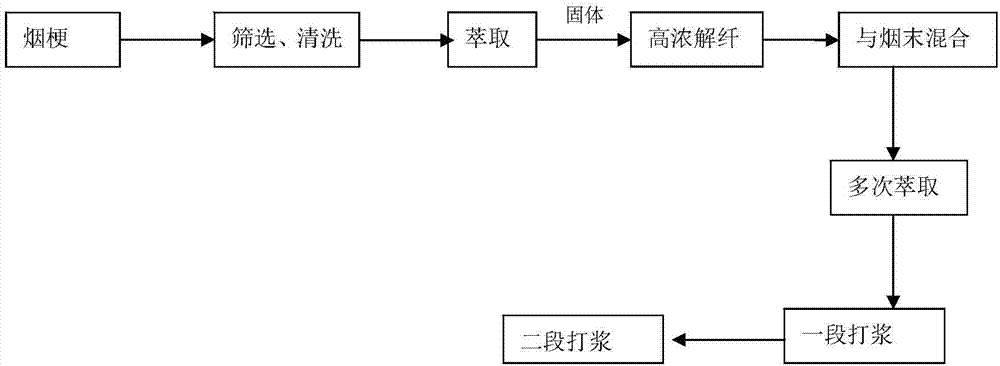

[0057] A kind of slurry preparation method of tobacco sheet in this embodiment, such as figure 1 shown, including the following steps:

[0058] (1) After the tobacco stems are screened and cleaned, the water-soluble substances in the tobacco stems are dissolved by extraction, and solid-liquid separation is carried out;

[0059] (2) After separation, the tobacco stems are subjected to high-concentration defiberization (that is, high-concentration defiberization), and then mixed with tobacco powder, and then extracted 2 to 4 times after mixing; wherein, the moisture content of the tobacco stems during high-concentration defiberization is 65% ~80%, using high-consistency grinding discs (that is, the disc structure composed of the following two cooperating defibrating discs) to defibrate. The process of high-consistency defibrating is through the relative The movement rubs and separates the tobacco stems;

[0060] (3) The extracted mixture is firstly subjected to one-stage beati...

Embodiment 2

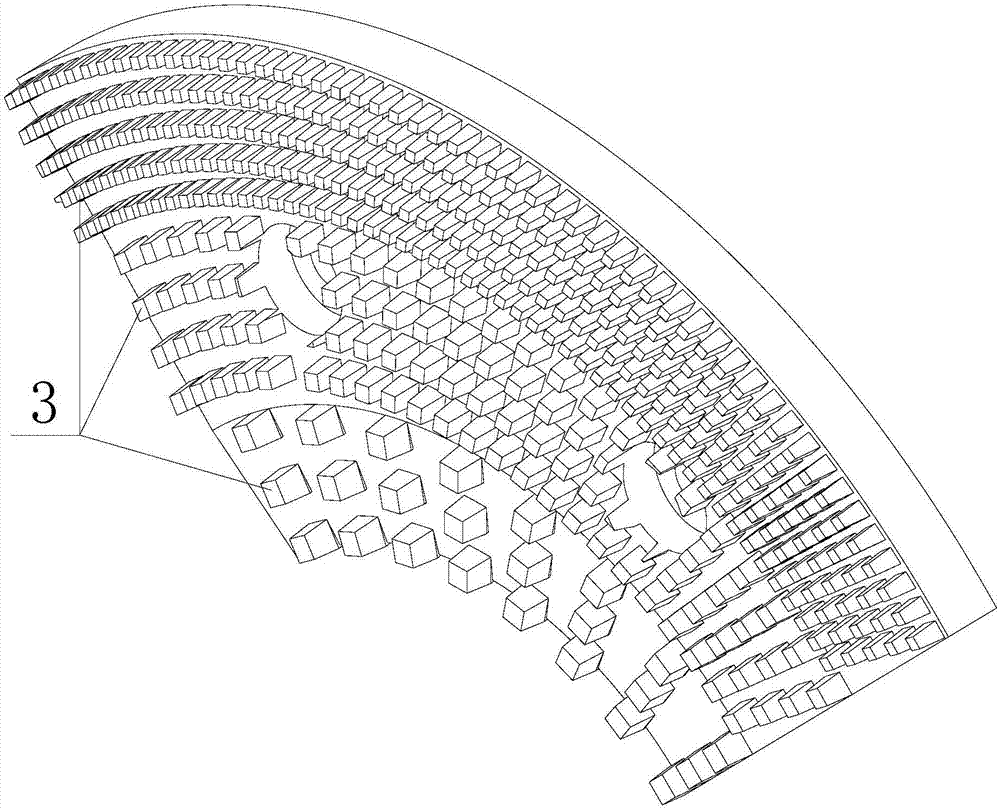

[0065] In this embodiment, a grinding disc structure for preparing tobacco sheet pulp is mainly used for the defibrating process of step (2) in the slurry preparation method described in Example 1, and the grinding disc structure includes two matching defibrating grinding discs , the defibrating grinding teeth 3 on the two defibrating discs are interlaced (such as Figure 4 shown), and form the first material flow channel 7 between the defibrating grinding teeth of the two defibrating grinding discs (as shown in Figure 5 8 shows tobacco stems, and 9 shows tobacco dust); among the two defibrating grinding discs, one is the defibrating dynamic grinding disc 2, and the other is the defibrating static grinding disc 1;

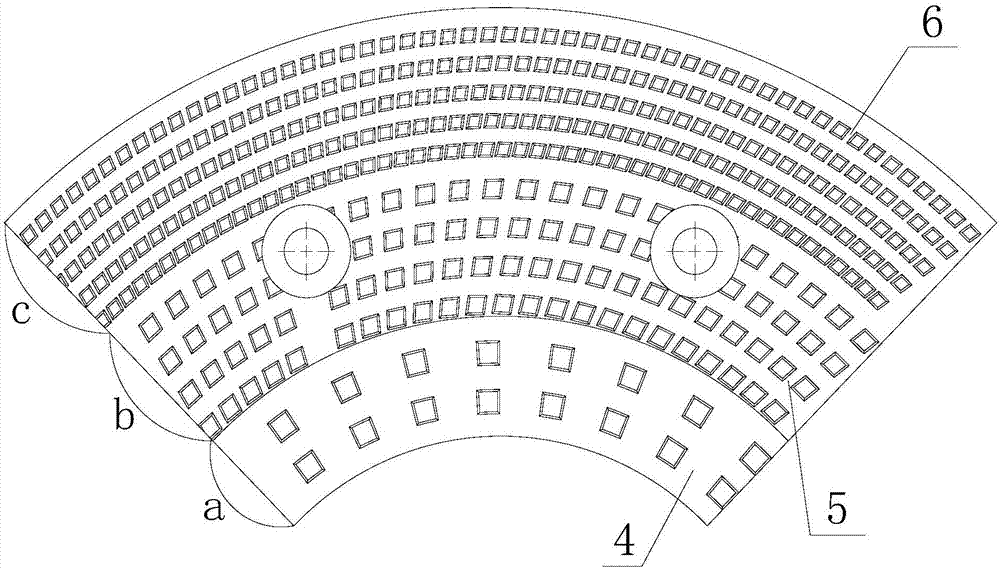

[0066] The two defibrating discs have the same structure and are both disc-shaped, such as figure 2 or image 3 As shown, from the center of the disc to the outer circumference, the defibrating grinding disc is provided with crushing area a, pre-defibrating are...

Embodiment 3

[0072] In this embodiment, a milling disc structure for preparing tobacco flakes is mainly used in the beating process of step (3) in the slurry preparation method described in Example 1. The milling disc structure includes two matching milling discs , one section of beating grinding teeth 12 on two sections of beating grinding discs are interlaced and embedded (such as Figure 9 shown), and form the second material flow through 13 between the first beating teeth of the two first beating grinding discs (as Figure 10 Shown, shown in figure 8 is tobacco stem, and shown in 9 is tobacco dust); Among the two sections of beating millstones, one is a section of beating dynamic millstone 10, and the other is a section of beating static millstone 11;

[0073] The two first-stage beating discs have the same structure and are both disc-shaped, such as Figure 6 or Figure 8 As shown, from the center of the disc to the outer circumference, a section of the beating grinding disc is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com