Treatment system and treatment method for adsorption, concentration and catalytic combustion of waste gas from paint spraying line

A catalytic combustion and exhaust gas treatment technology, applied in the direction of combustion methods, gas treatment, chemical instruments and methods, etc., can solve the problems of physical treatment methods such as ineffective treatment, affecting human health, and inability to recycle, so as to achieve reasonable facility layout, The effect of reducing secondary pollution and convenient maintenance and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

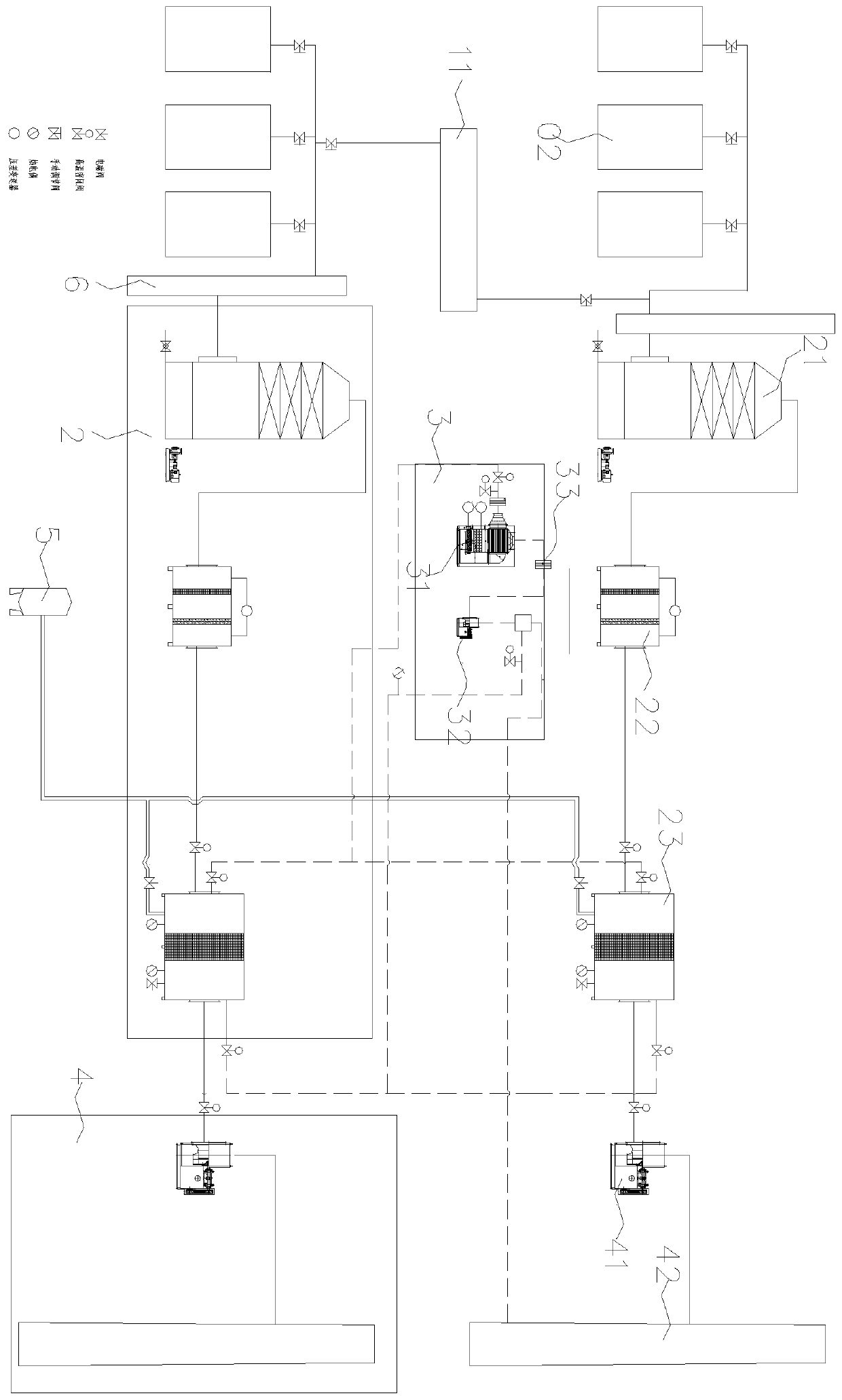

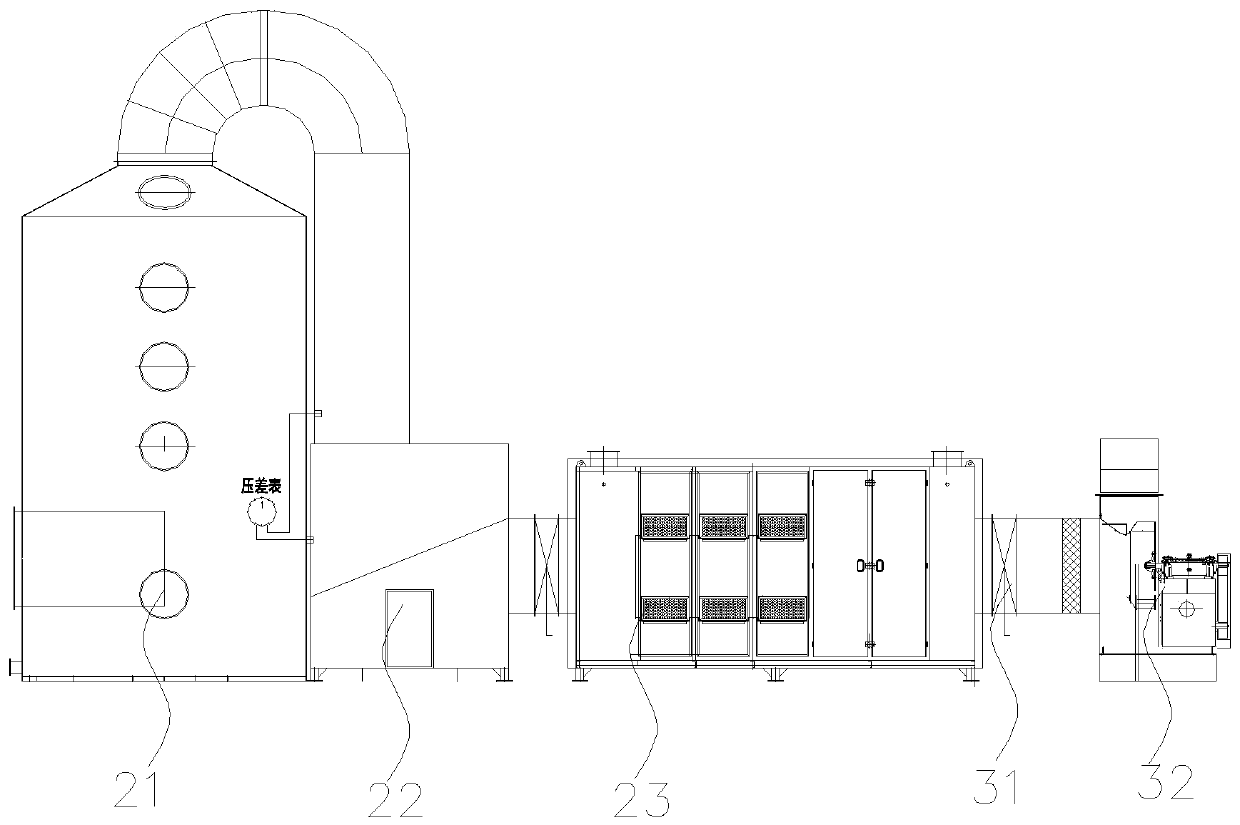

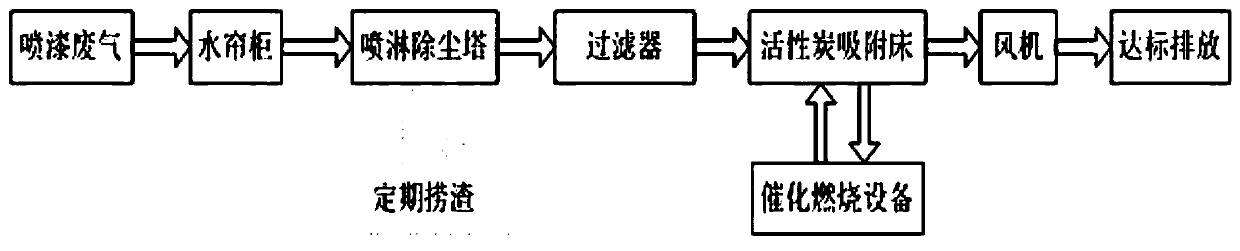

[0038] figure 1 Schematically shows a painting line exhaust gas adsorption concentration catalytic combustion treatment system according to an embodiment of the present invention, including a curing furnace 11, a painting booth 12, and several exhaust gas treatment modules 2, catalytic combustion modules 3 and discharge modules 4. The curing furnace 11 and the paint spraying room 12 are respectively connected to the input ends of several waste gas treatment modules 2 through pipes, and the output pipes of the curing furnace 11 and the paint spraying room 12 are equipped with regulating valves; the catalytic combustion module 3 is connected to several waste gas treatment modules 2 through pipes And form a circulation loop; the output end of the exhaust gas treatment module 2 is connected to the discharge module 4 pipes; the input end of the catalytic combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com