High-strength sewing thread

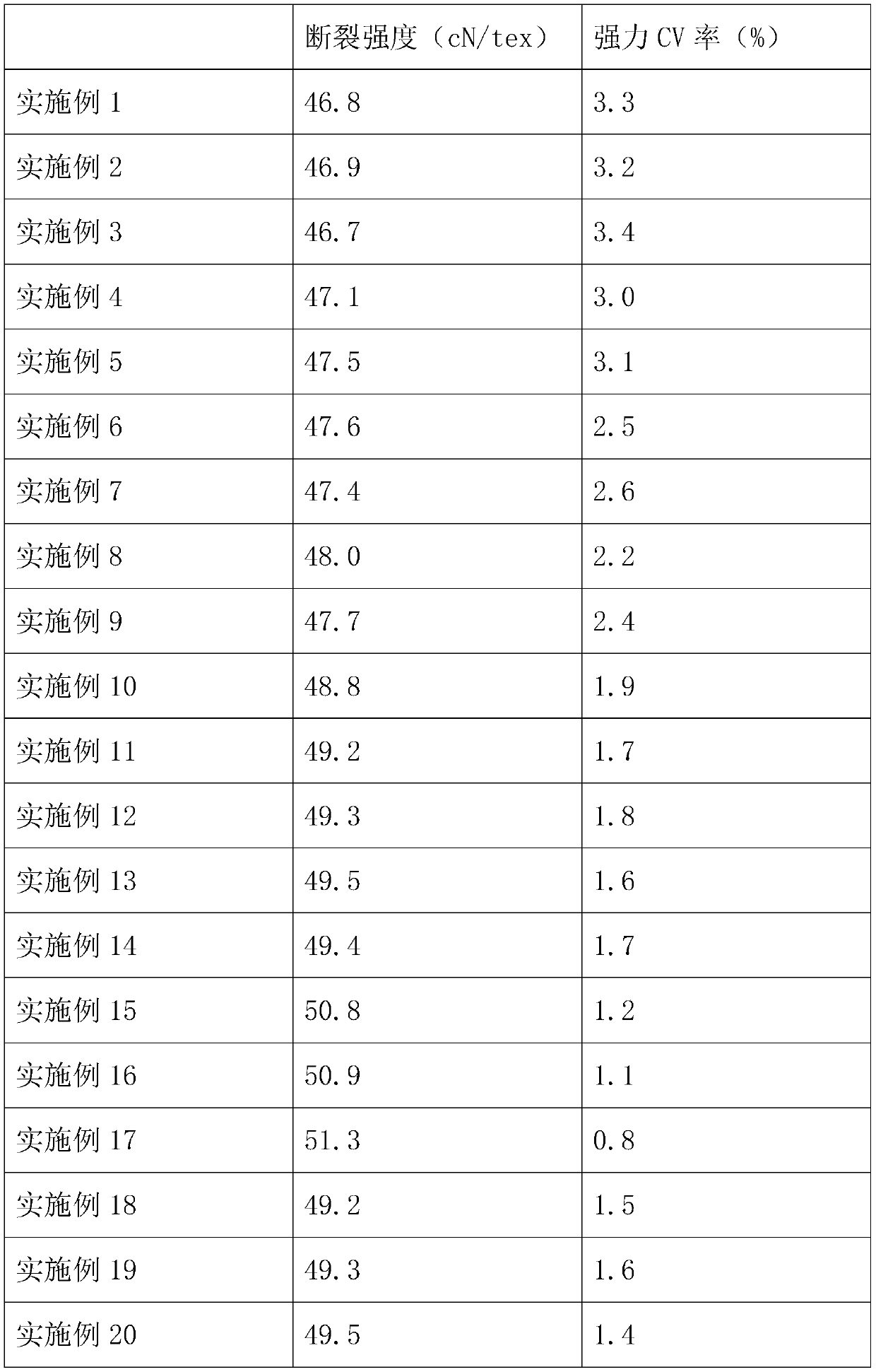

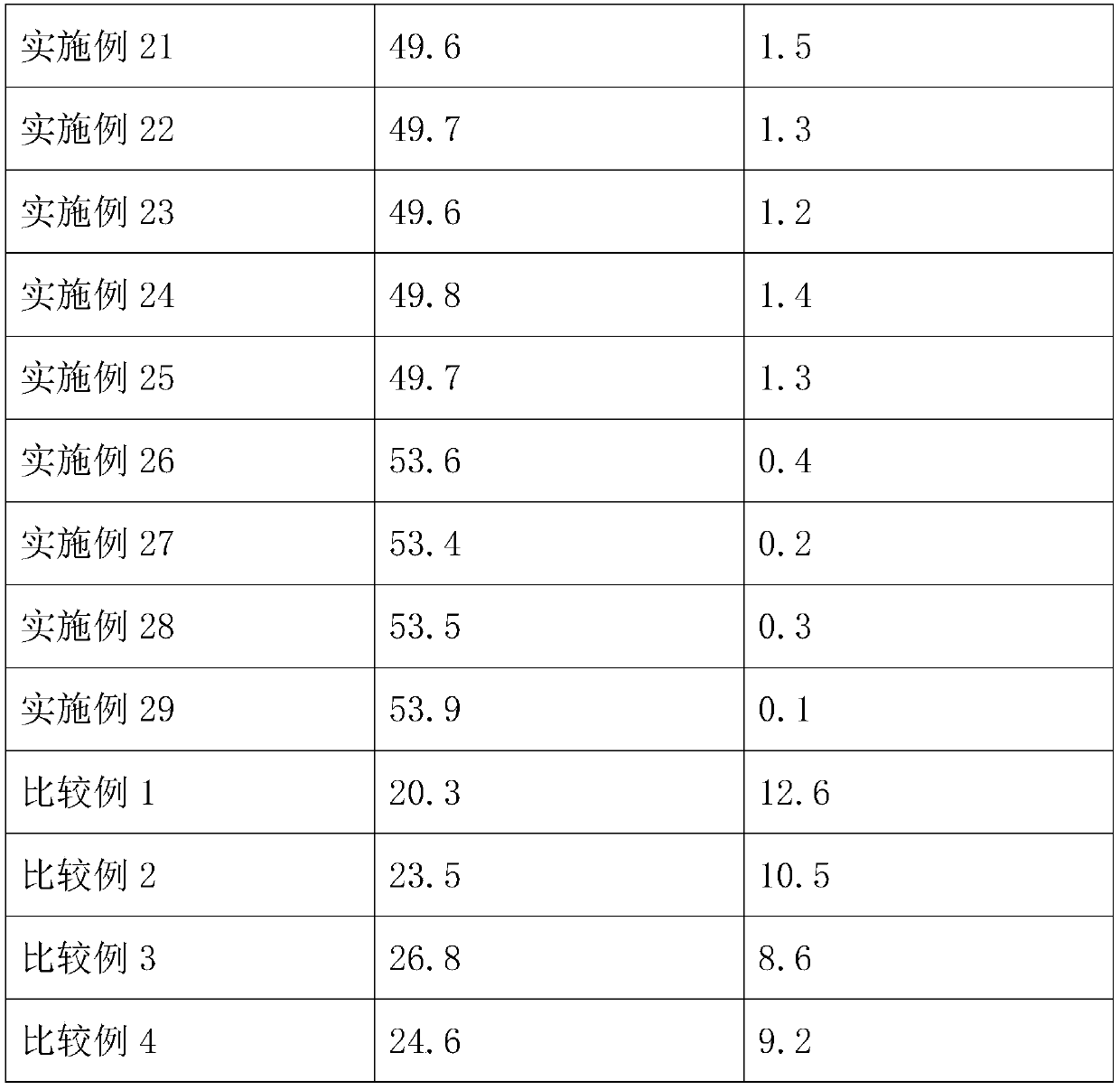

A sewing thread and high-strength technology, applied in the field of sewing materials, can solve the problems of low breaking strength and high strength CV rate of sewing threads, and achieve the effects of low strength CV rate, high breaking strength and reducing strength CV rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

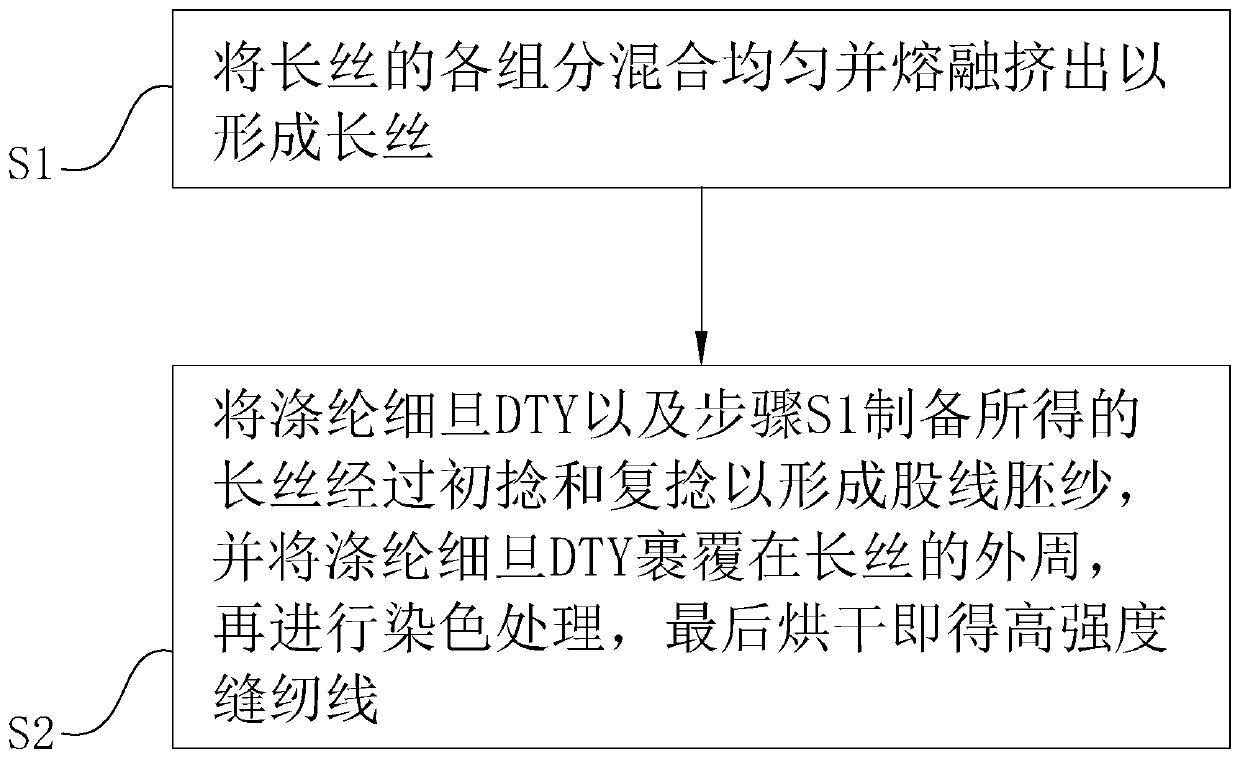

[0058] A preparation method for high-strength sewing thread, comprising the following steps:

[0059] S1, prepare filament, specifically as follows:

[0060] Add polytetrafluoroethylene resin 55kg, polypropylene resin 30kg, 5-amino-3-cyclohexyl-1-methyl-1H-pyrazole-4-formonitrile 1.5kg, 2-ethanediol to the twin-screw melt spinning machine Base-4-methyl-6-piperazine-1-pyrimidine 0.3kg, polyoxyethyl glyceryl ether 1kg, mix uniformly to form a mixture, and control the temperature of melt extrusion to 235°C so that the mixture is melted and extruded to form filament.

[0061] S2, prepare high-strength sewing thread, specifically as follows:

[0062] The polyester fine denier DTY and the filament prepared in step S1 are first twisted and retwisted to form a strand embryo yarn, wherein the ratio of the polyester fine denier DTY to the filament is 4:1, and the polyester fine denier DTY is wrapped On the periphery of the filament, it is dyed, and finally dried to obtain a high-stre...

Embodiment 2

[0064] The difference from Example 1 is that in step S1, 57.5 kg of polytetrafluoroethylene resin, 27.5 kg of polypropylene resin, 5-amino-3-cyclohexyl-1-methyl-1H- Pyrazole-4-carbonitrile 2kg, 2-ethyl-4-methyl-6-piperazine-1-pyrimidine 0.4kg, polyoxyethyl glyceryl ether 0.5kg.

Embodiment 3

[0066] The difference from Example 1 is that in step S1, 60 kg of polytetrafluoroethylene resin, 25 kg of polypropylene resin, 5-amino-3-cyclohexyl-1-methyl-1H-pyrazole are added to the twin-screw melt spinning machine - 1 kg of 4-formazine, 0.5 kg of 2-ethyl-4-methyl-6-piperazine-1-pyrimidine, and 0.75 kg of polyoxyethyl glycerol ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com