Straw smashing and returning device with function of spraying straw rotting agent

A technology of straw crushing and humus agent, which is applied in the direction of agricultural machinery and implements, crop processors, cutters, etc., can solve the problems of long decay time of straw, inability to spray the humus agent evenly, lack of spraying of the humus agent, etc., to achieve The effect of reducing time and increasing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

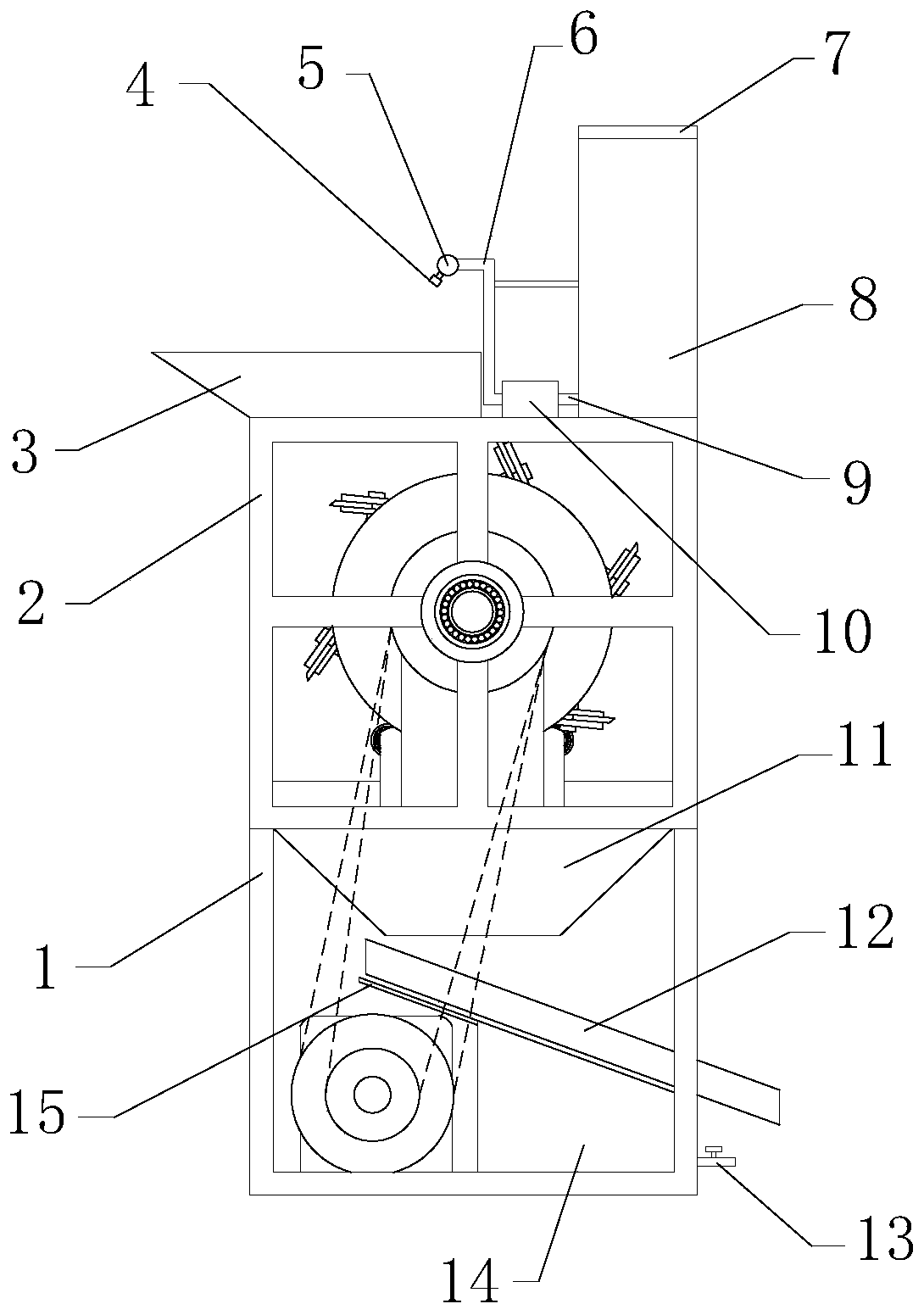

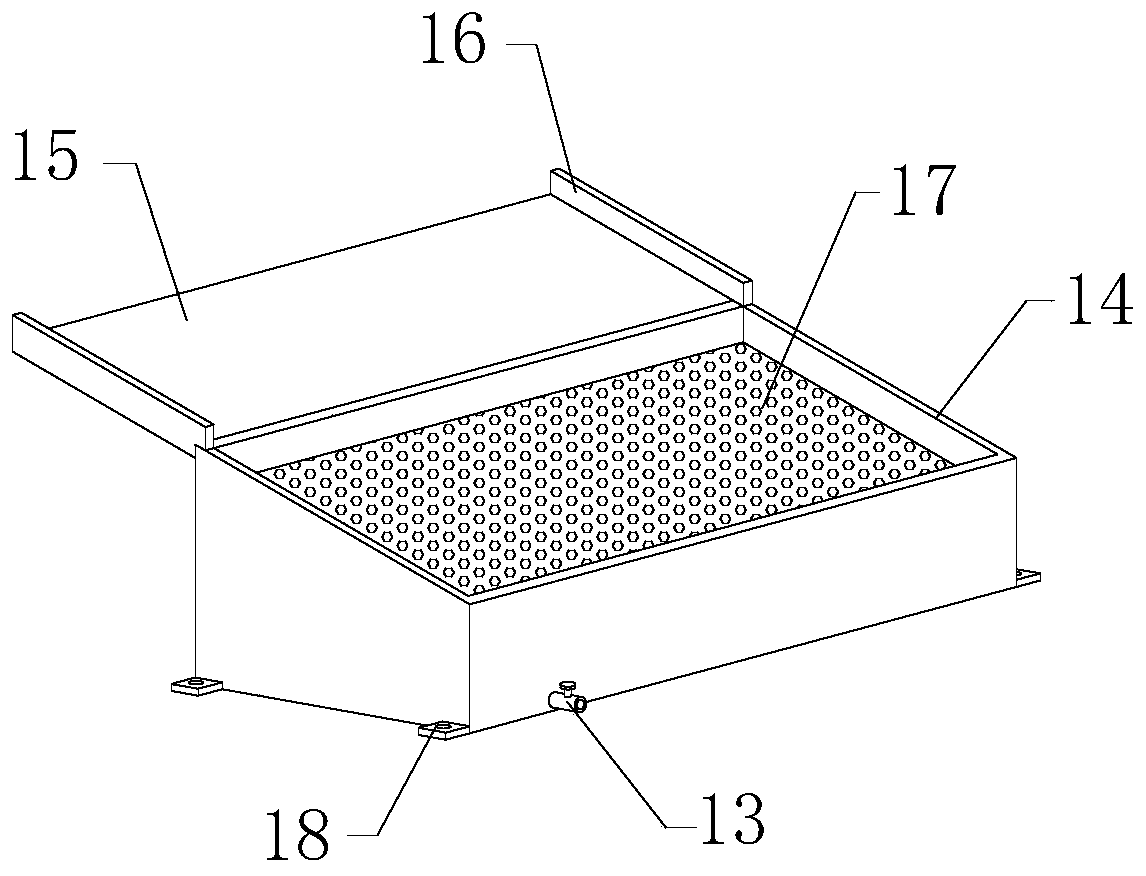

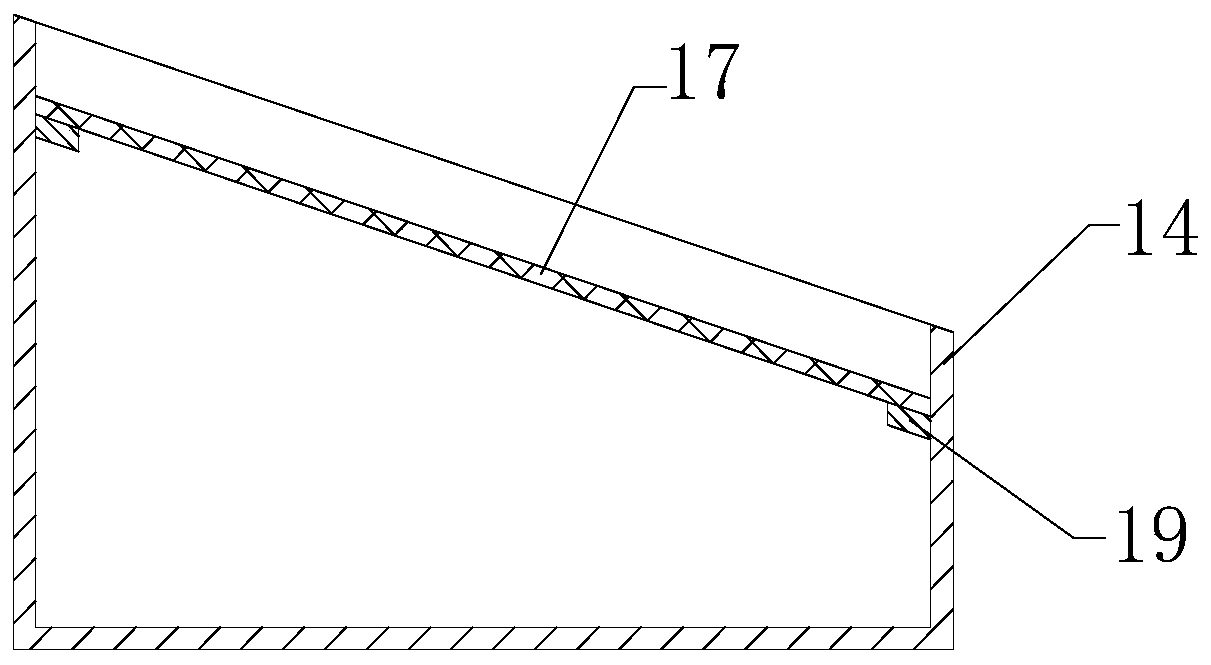

[0019] See Figure 1 to Figure 4 , The present invention provides a technical solution: a straw crushing and returning device with the function of spraying stalk agent, comprising a frame 1, a crushing box 2 installed on the upper end of the frame 1, and a swaying installation of the crushing box 2 outlet 11 On the lower grid baffle 12, a liquid storage tank 8 is installed on the upper end of the crushing box 2, and a tank cover 7 is installed on the upper end of the liquid storage tank 8. An appropriate amount of stalk agent is added to the liquid storage tank 8, and then the tank cover 7 is covered to prevent miscellaneous The objects fall into the stalk decay agent in the liquid storage tank 8.

[0020] A connecting pipe 9 is installed on the lower sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com