Ruthenium nanoparticle/three-dimensional porous carbon nitride composite material, preparation method and application thereof

A nanoparticle, three-dimensional porous technology, applied in chemical instruments and methods, catalyst activation/preparation, hydrogen/synthesis gas production, etc., can solve problems such as limited application and high price, and achieve reduced recombination rate, high surface atomic ratio, The effect of promoting interfacial charge transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

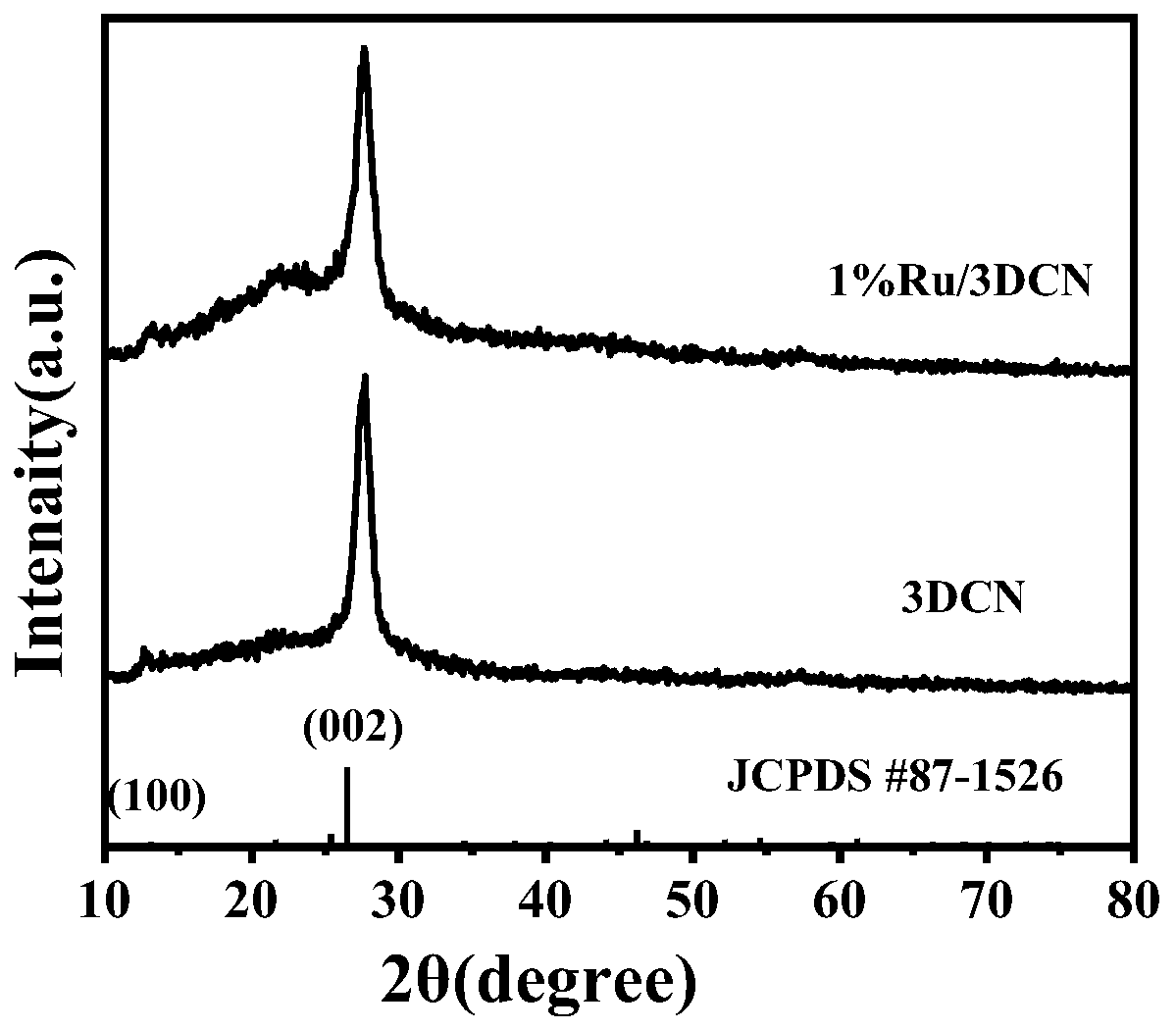

[0028] Example 1 Preparation of 3DCN nanosheets

[0029] The preparation of 3DCN nanosheets adopts thermal polymerization method: Weigh 2.5224g of melamine and 2.5814g of cyanuric acid in a mortar, put them in a beaker after grinding and mixing, add deionized water, stir magnetically at room temperature for 12h, and pass through 6000rad / Centrifuge for 5 min to obtain the lower layer solid, and then freeze-dry in a vacuum freeze dryer for 24 hours to obtain a white cyanuric acid-melamine (CM) supramolecular precursor; subsequently, all the obtained CM supramolecular precursors are poured into a crucible with a lid , transferred to a heating tube furnace with automatic program temperature control, and calcined in air at 550°C for 4h at a heating rate of 5°C / min. Yellow 3DCN solid powder.

Embodiment 2

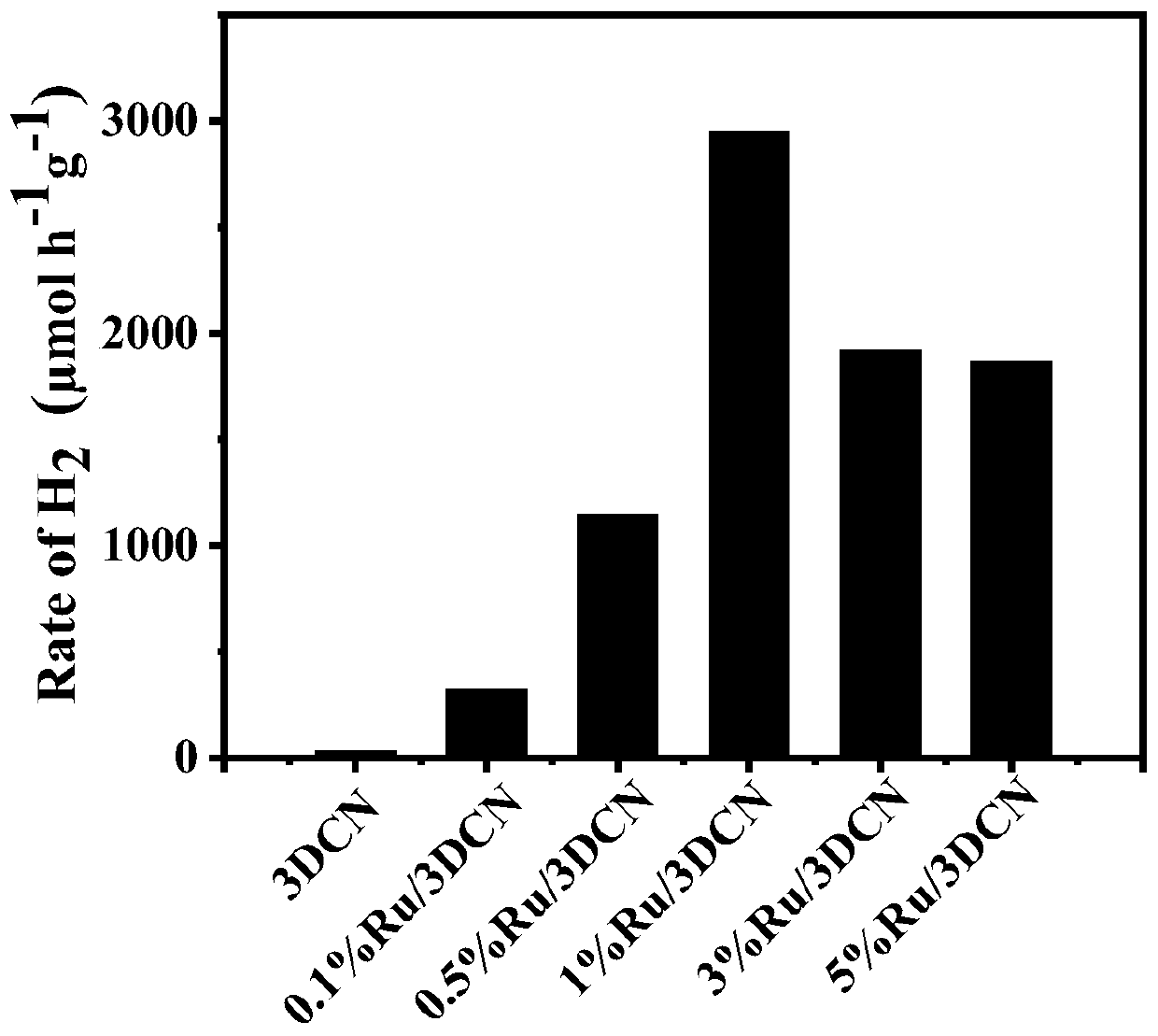

[0030] Example 2 Preparation of 0.1%Ru / 3DCN composite material

[0031] Ultrafine Ru nanoparticles / 3DCN composites were prepared by solvothermal-assisted polyol reduction method: 0.0998g of 3DCN was dispersed in 60ml of ethylene glycol, and 40μl of 5mg·ml was pipetted with a pipette gun. -1 RuCl 3 ethylene glycol solution, then add 0.0007g CTAB, and obtain a uniform and stable suspension through ultrasonic treatment for 30min and magnetic stirring for 2h; then transfer the resulting suspension to a polytetrafluoroethylene-lined autoclave In an oven, conduct a hydrothermal reaction at 140°C for 18 hours; after naturally cooling to room temperature, centrifuge at 6,000 rad / min for 5 minutes, wash with deionized water and absolute ethanol three times each, place in a vacuum oven at 60°C, dry for 12 hours, and take it out. Grind to powder with a mortar to obtain 0.1%Ru / 3DCN composite material.

Embodiment 3

[0032] Preparation of Example 3 0.5% Ru / 3DCN composite material

[0033]Ultrafine Ru nanoparticles / 3DCN composites were prepared by solvothermal-assisted polyol reduction method: 0.0990 g of 3DCN was dispersed in 60 ml of ethylene glycol, and 200 μl of 5 mg ml was pipetted with a pipette gun. -1 RuCl 3 ethylene glycol solution, then add 0.0035g CTAB, after ultrasonic treatment for 30min and magnetic stirring for 2h to obtain a uniform and stable suspension; then transfer the resulting suspension to a polytetrafluoroethylene-lined autoclave, In an oven, conduct a hydrothermal reaction at 140°C for 18 hours; after naturally cooling to room temperature, centrifuge at 6,000 rad / min for 5 minutes, wash with deionized water and absolute ethanol three times each, place in a vacuum oven at 60°C, dry for 12 hours, and take it out. Grind to powder with a mortar to obtain 0.5%Ru / 3DCN composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com