Deep drawing forming method for metal housing of deep cylindrical part and multi-pass one-time forming die

A technology for metal shells and deep cylindrical parts, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc. It can solve the problems of blank lateral movement and multiple positioning of sheet metal, so as to avoid movement, reduce the probability of waste, and reduce jamming. mod effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

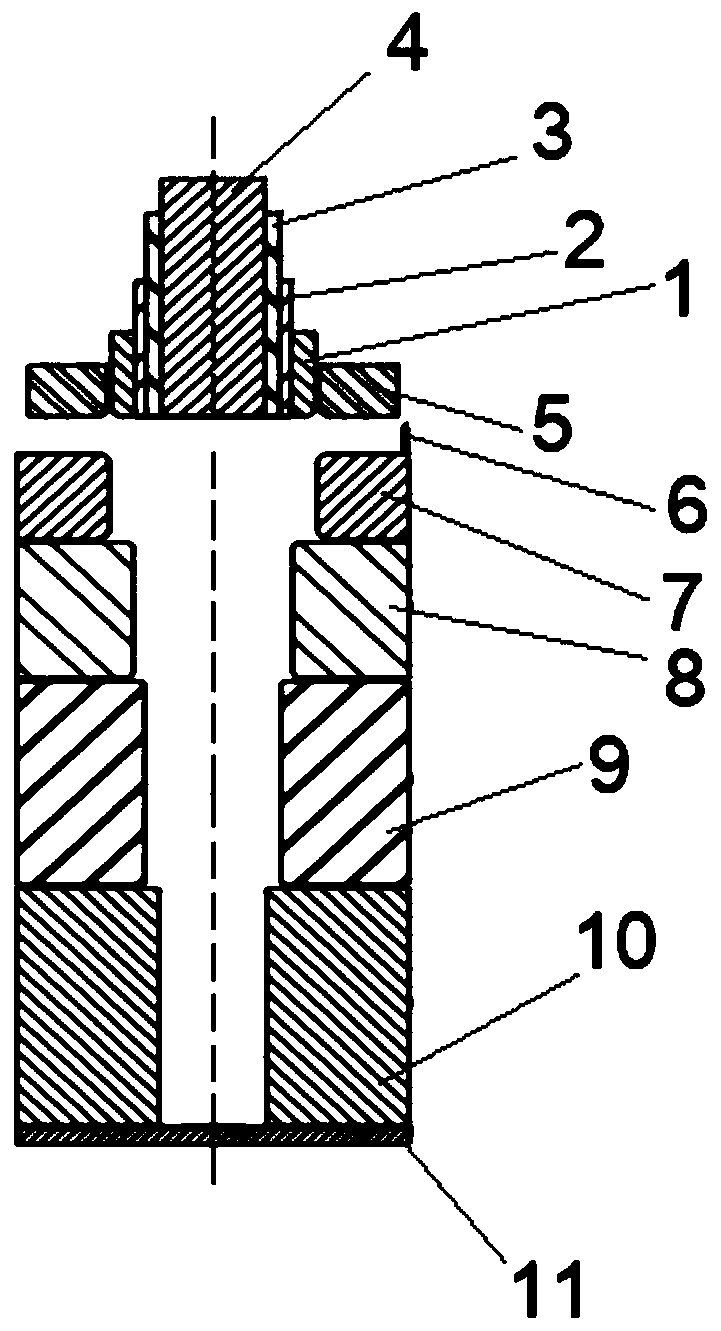

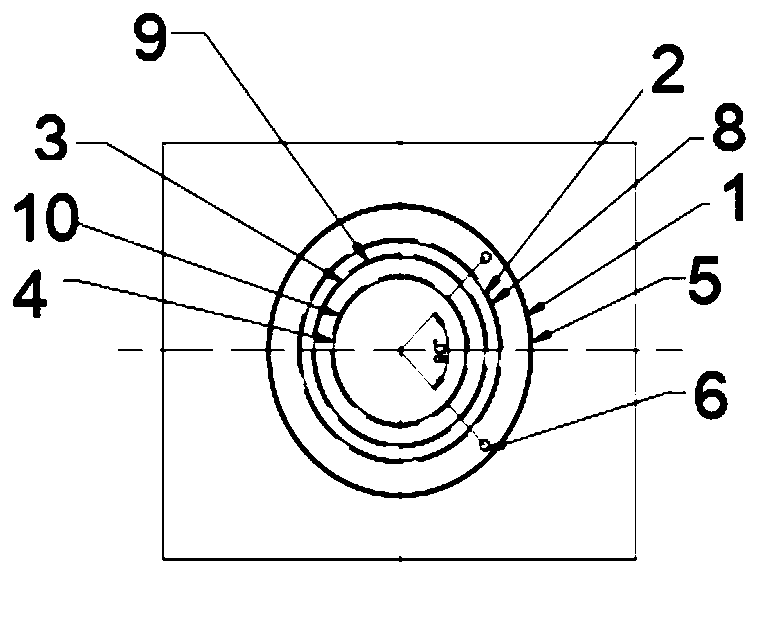

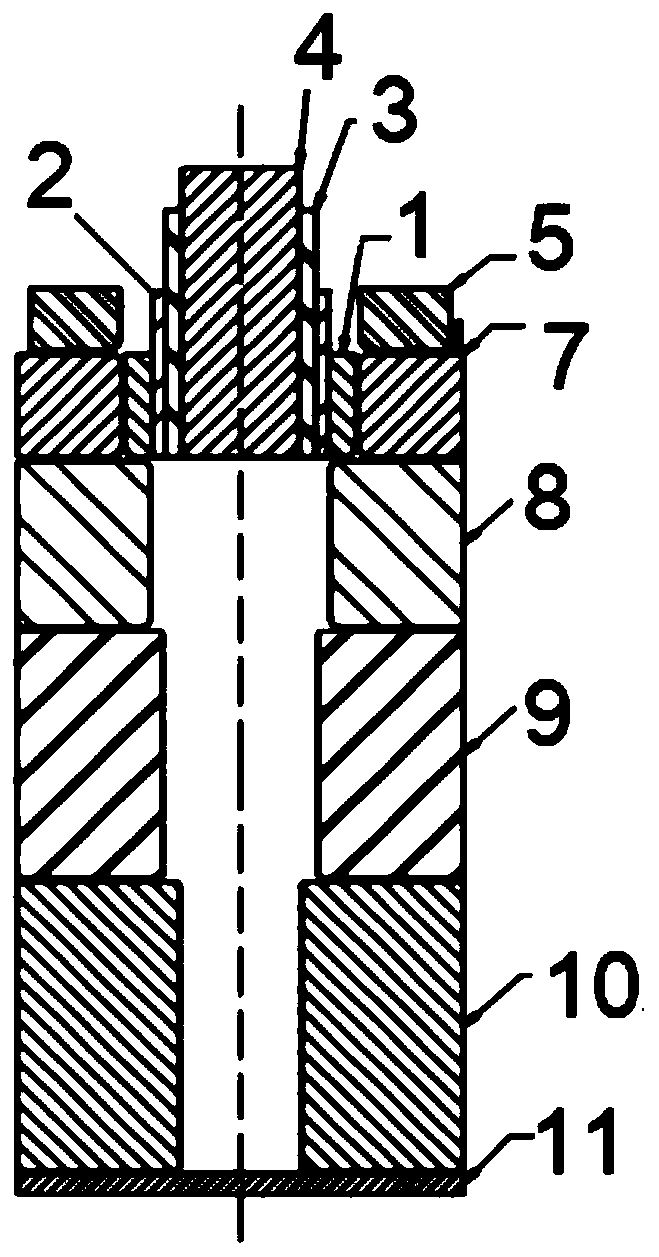

[0041] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

[0042] The method for deep-drawing the metal shell of the deep cylindrical part is as follows: (1) Blanking; (2) Positioning of the sheet; (3) 5 pressing of the blank holder; (4) Multi-pass forming at one time. The method for deep-drawing and forming the metal shell of the deep cylindrical part of the present invention can realize the deep-drawing and forming of the deep cylindrical metal shell in multiple passes at one time, which saves the sheet metal lateral movement, positioning and other processes in the multi-step continuous drawing process, and at the same time reduces many The probability of scrap generated during deep drawing.

[0043] Step (4) multi-channel one-time forming is realized by multi-channel one-time forming mold, such as figure 1 and figure 2 As shown, the multi-pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com