On-line stripping and pasting printing device and printing method thereof

A technology of printing equipment and gluing, which is applied in printing, printing machines, rotary printing machines, etc., can solve the problems of interruption of printing work and inability to realize continuous production of printing equipment, and achieve the effect of improving efficiency and printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] This part will describe the specific embodiment of the present invention in detail, and the preferred embodiment of the present invention is shown in the accompanying drawings. Each technical feature and overall technical solution of the invention, but it should not be understood as a limitation on the protection scope of the present invention.

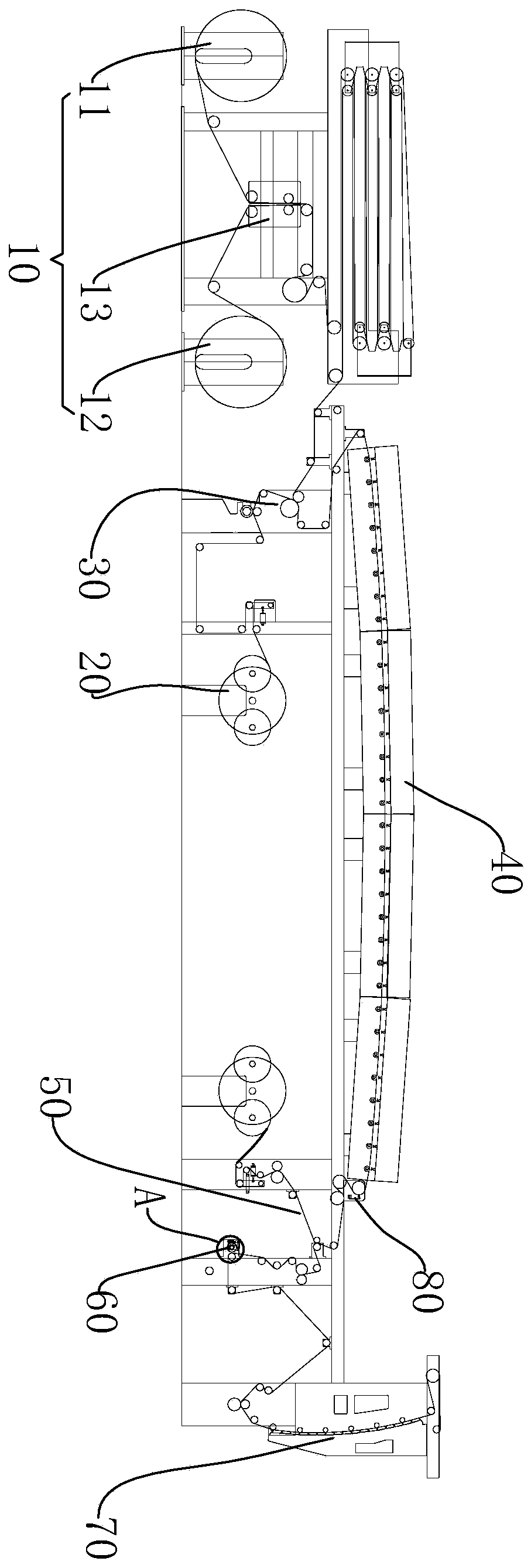

[0030] see Figure 1 to Figure 3 , a printing device for on-line film peeling and gluing, comprising: a paper unwinding unit 10, the paper unwinding unit 10 comprising a first unwinding assembly 11, a second unwinding assembly 12, and the first unwinding assembly capable of The zero-speed splicing device 13 that splices the end of the paper output by the assembly 11 with the head end of the paper output by the second unwinding assembly 12. The working principle of the zero-speed splicing device 13 can be referred to the applicant's previous patent application documents. The application number of the patent application document...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com