Round rebar feeding device

A feeding device and steel bar technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems that cannot meet the requirements of round bar steel bar transportation, increase labor costs, and limit the use range, etc., to achieve design saving Electricity, high positioning efficiency, convenient post-maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

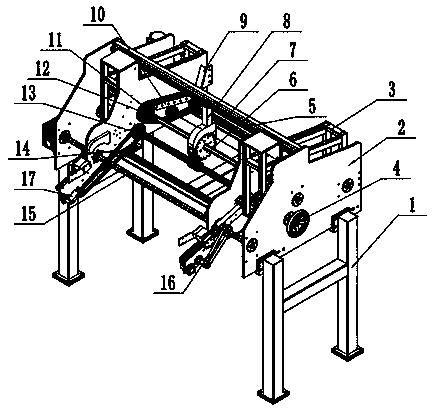

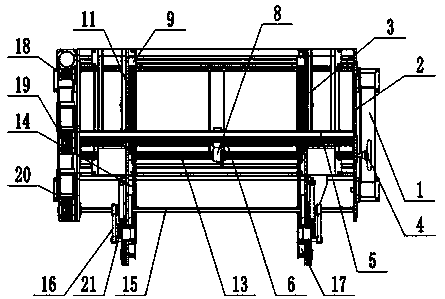

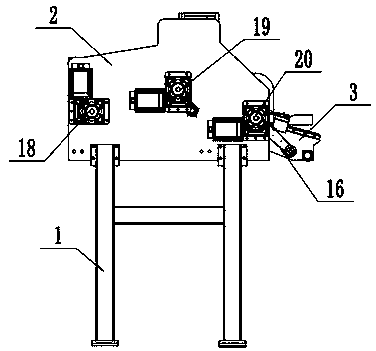

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] This example: see Figure 1-Figure 3 , a round bar steel feeding device, including a frame 1, and two corresponding left and right moving frames 3 are arranged on the frame 1, and each moving frame 3 can move left and right on the frame 1, and the moving method can adopt a chute The method is to set a chute on the frame 1 so that the mobile frame 3 can slide left and right along the chute, but it is not limited to this. At the same time, the frame 1 is provided with two corresponding base plates 2, and the mobile frame 3 is located 2, a support rod 5 is provided between the two substrates 2, and the substrate 2 is set to protect the mobile frame 3. The wheel 4 is provided with a first motor 19 , a second motor 20 and a third motor 18 outside the other base plate 2 .

[0032] Simultaneously, in order to drive the mobile frame 2 to move more conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com