A split conductive ceramic boat

A conductive ceramic, split-type technology, applied in the direction of metal material coating process, vacuum evaporation plating, coating, etc., can solve the problem that metal melting and evaporation stability are greatly affected, affecting large-scale metal evaporation efficiency, conductive ceramic boat Easy to damage and other problems, to avoid changes, maintain stability, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

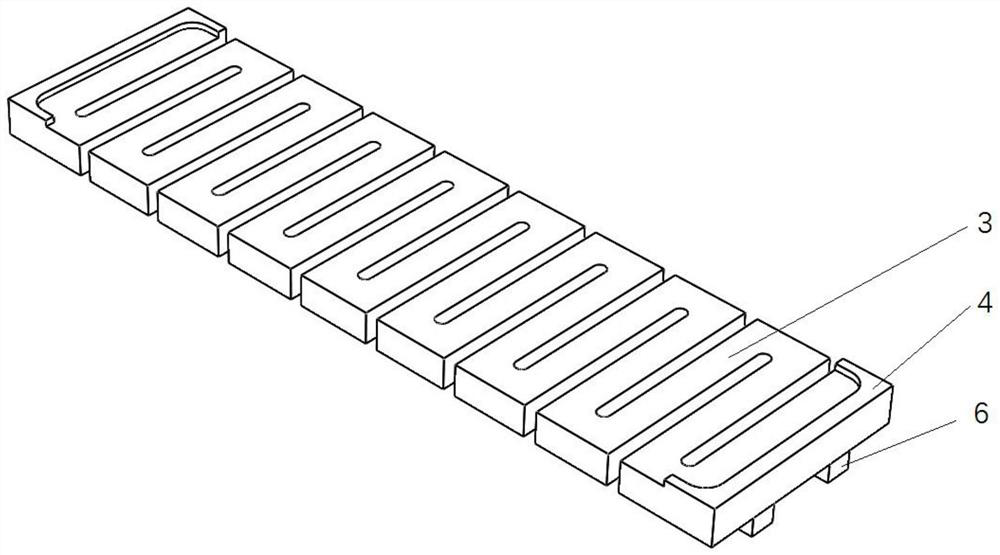

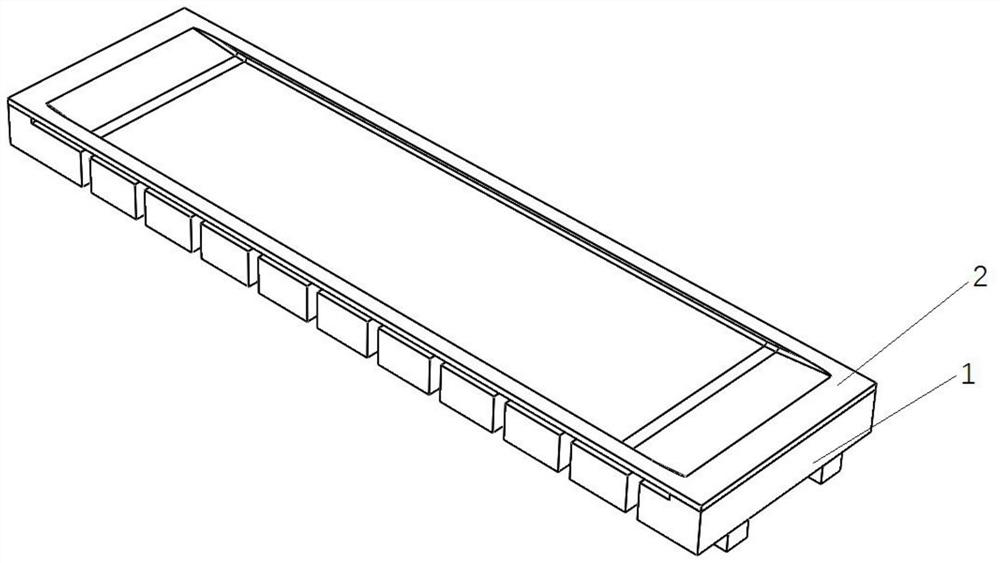

[0026] A split-type conductive ceramic boat, including two parts: a graphite heater and a graphite ceramic boat; the graphite heater is in the shape of a cuboid as a whole, the middle part of the graphite heater is a continuous folded strip, and the top of both ends of the graphite heater are equipped with U-shaped The boss, the U-shaped openings of the two U-shaped bosses are arranged opposite to each other, and the two ends of the graphite heater are connected to the power supply.

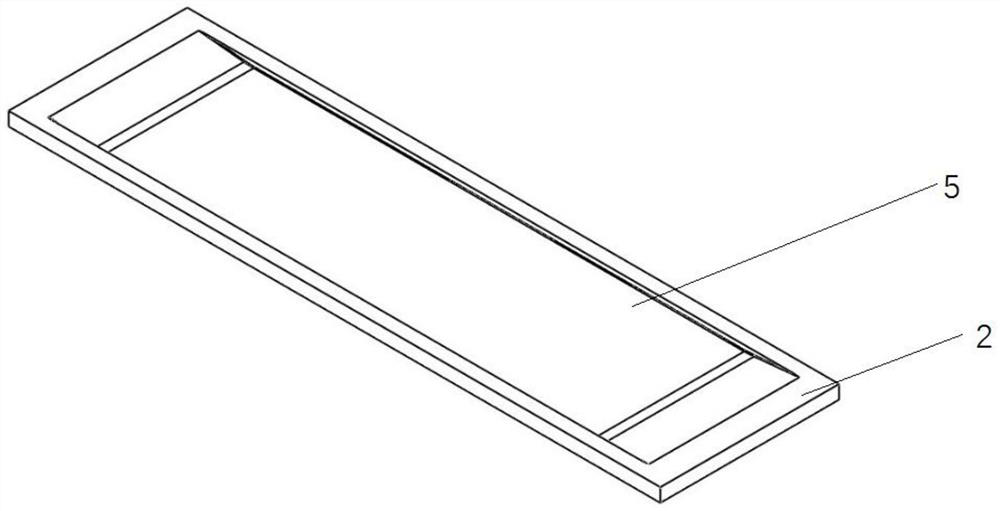

[0027] The graphite ceramic boat is a cuboid plate with a groove on the upper part, which is used to contain molten metal material. The bottom contour of the graphite ceramic boat is consistent with the contours of the two U-shaped bosses of the graphite heater.

[0028] The length of the graphite heater is 200mm, the width is 50mm, and the height is 20mm. Both ends of the heater are connected to the power supply. The heater as a whole contains 20 folded strips. The folded strips are long strips, ...

Embodiment 2

[0036] A split type conductive ceramic boat, its structure is as described in Embodiment 1, the difference is that the U-shaped openings of the two U-shaped bosses are provided with slopes. When the graphite ceramic boat is put in, it is gradually compressed from top to bottom for self-tightening.

Embodiment 3

[0038] A split type conductive ceramic boat, its structure is as described in embodiment 1, the difference is that a graphite material fixing rod is arranged between the two ends of the bottom of the graphite heater, the length of the fixing rod is 200mm, the width is 10mm, and the height is 10mm , with a symmetrical distribution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com