Electrically controlled rammer for workshop construction

A ramming machine and electric control technology, applied in construction, soil protection, infrastructure engineering, etc., can solve problems such as small turning radius, inconvenient use, and large ramming machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

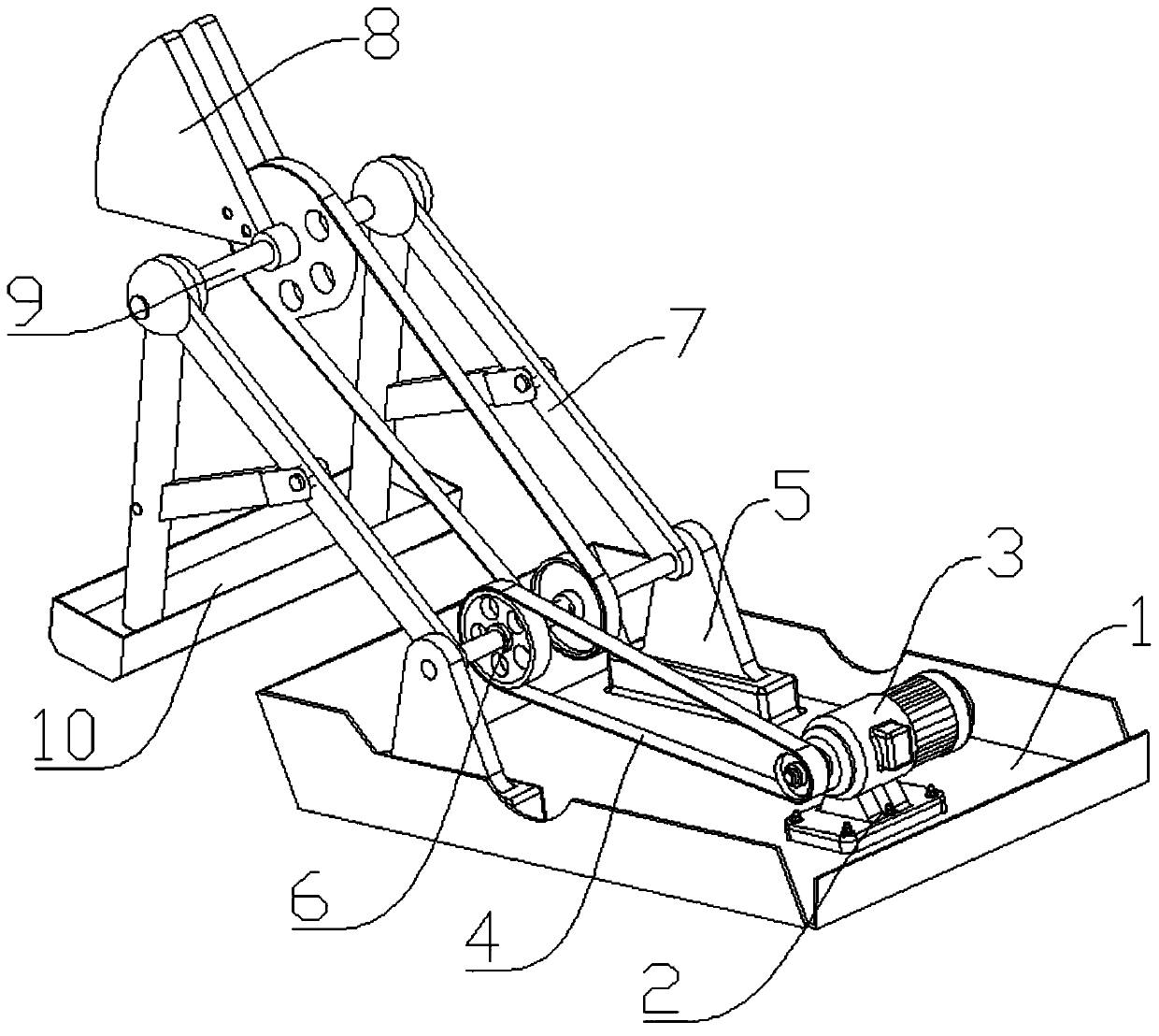

[0015] Such as figure 1 As shown, an electric control ramming machine for factory building construction includes installation and fixing box 1, motor base 2, motor 3, transmission flat belt 4, and fixing support arm 5. The installation and fixing box 1 is used to fix parts, and the installation and fixing box 1 is provided with a motor base 2, the motor base 2 is used to fix the motor 3, the motor 3 is provided above the motor base 2, the motor 3 is used to provide power, one end of the motor 3 is provided with a transmission flat belt 4, and the transmission flat belt 4 For power transmission, one end of the transmission flat belt 4 is provided with a flat pulley 6, the flat pulley 6 is used for power transmission, the two sides of the flat pulley 6 are provided with fixed arms 5, and the fixed arms 5 play a supporting role , the top of the fixed support arm 5 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com