Mechanism capable of realizing forward transmission for two-way driving and reverse transmission for one-way locking

A locking mechanism and two-way drive technology, applied in the field of vehicles, can solve the problems of high cost, difficult research and development, and difficulty in mastering, and achieve the effects of low manufacturing cost and maintenance cost, small space layout difficulty, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

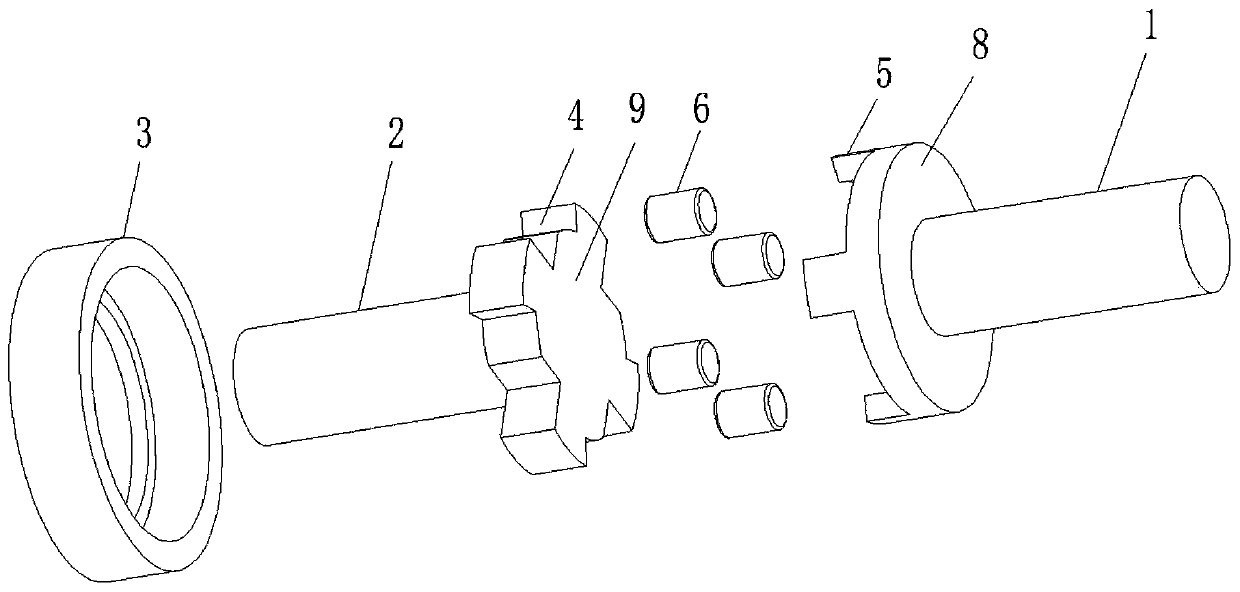

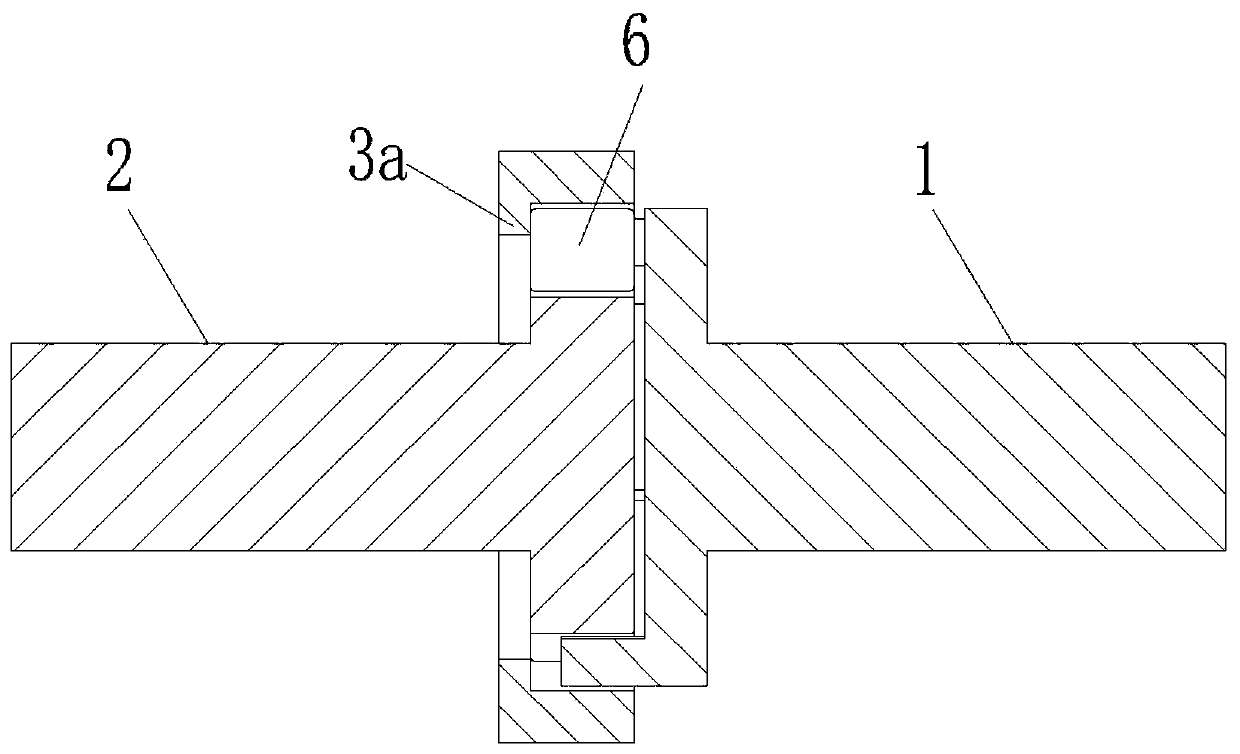

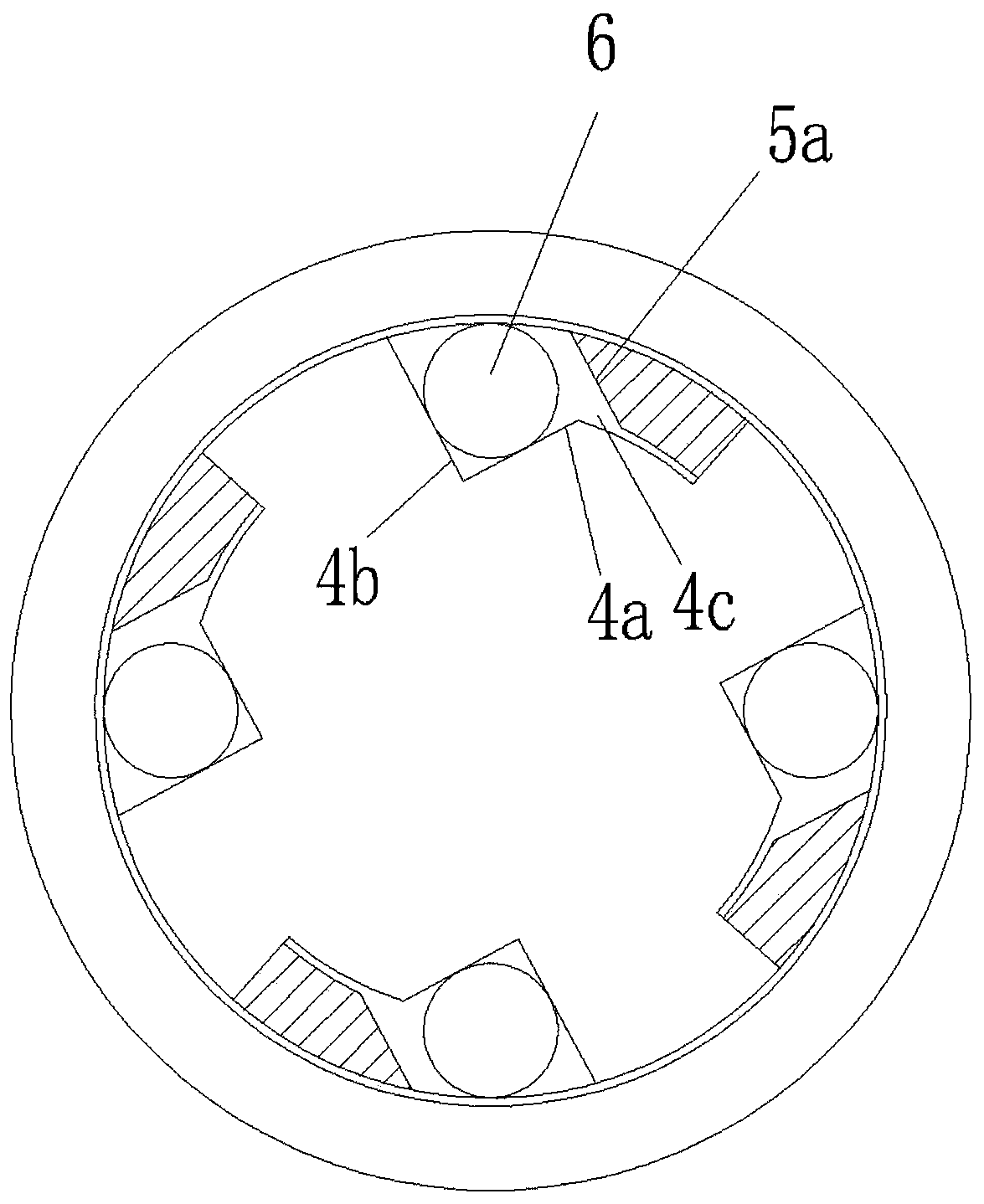

[0027] As shown in the figure, the forward bidirectional drive and reverse unidirectional locking mechanism in this embodiment includes a driving shaft 1, a driven shaft 2 and a fixed housing 3. A locking groove 4 is formed on the end surface of the driven shaft. The end face of the shaft has a coupling tooth 5, the coupling tooth is located in the locking groove to realize the transmission cooperation between the driving shaft and the driven shaft, the fixed housing is sleeved on the joint between the driving shaft and the driven shaft, and a locking mechanism is arranged in the locking groove , the locking mechanism has at least two states of being away from the inner wall of the fixed housing and being pressed against the inner wall of the fixed housing. The driving shaft and the driven shaft are in normal transmission cooperation, and during the inversion process of the driven shaft in reverse transmission, the locking mechanism is pressed against the inner wall of the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com