A sealing device suitable for corrosive liquids

A sealing device and corrosive technology, applied in the field of sealing device for corrosive liquid and sealing device for filling liquid, can solve the problem of difficult to achieve long-term sealing effect, poor elasticity of polytetrafluoroethylene, sticking between polytetrafluoroethylene and metal shell. In order to meet the sealing requirements, realize the sealing effect, and meet the corrosion resistance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

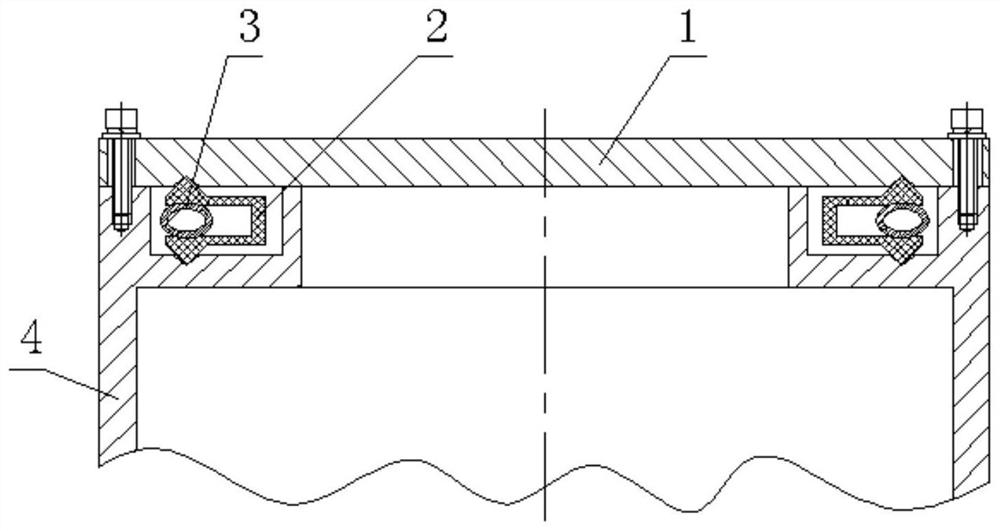

[0047] Such as figure 1 As shown, this embodiment provides a sealing device suitable for corrosive liquids, including an upper part 1, which is characterized in that it also includes a sealing element 2, an annular spring 3, and a lower part 4;

[0048] The upper part 1 is the first circular plate, the first circular plate of the upper part 1 is a body of revolution, the lower surface of the first circular plate of the upper part 1 is the first circular plane, and the first circular plane of the upper part 1 has a circle of the first circular plane. An annular groove, the shaft section of the first annular groove of the upper part 1 is an inverted V shape, and the rotation axis of the first annular groove of the upper part 1 coincides with the axis of the rotary body of the upper part 1;

[0049] The upper part 1 is the upper part of the mechanical connection interface in the liquid-phase charge shell, and the liquid-phase charge is located at the lower end of the upper part 1...

Embodiment 2

[0092] Such as figure 1 As shown, this embodiment provides a sealing device suitable for corrosive liquids, including an upper part 1, which is characterized in that it also includes a sealing element 2, an annular spring 3, and a lower part 4;

[0093] The upper part 1 is the first circular plate, the first circular plate of the upper part 1 is a body of revolution, the lower surface of the first circular plate of the upper part 1 is the first circular plane, and the first circular plane of the upper part 1 has a circle of the first circular plane. An annular groove, the shaft section of the first annular groove of the upper part 1 is an inverted V shape, and the rotation axis of the first annular groove of the upper part 1 coincides with the axis of the rotary body of the upper part 1;

[0094] The upper part 1 is the upper part of the mechanical connection interface in the liquid-phase charge shell, and the liquid-phase charge is located at the lower end of the upper part 1...

Embodiment 3

[0137] Such as figure 1 As shown, this embodiment provides a sealing device suitable for corrosive liquids, including an upper part 1, which is characterized in that it also includes a sealing element 2, an annular spring 3, and a lower part 4;

[0138] The upper part 1 is the first circular plate, the first circular plate of the upper part 1 is a body of revolution, the lower surface of the first circular plate of the upper part 1 is the first circular plane, and the first circular plane of the upper part 1 has a circle of the first circular plane. An annular groove, the shaft section of the first annular groove of the upper part 1 is an inverted V shape, and the rotation axis of the first annular groove of the upper part 1 coincides with the axis of the rotary body of the upper part 1;

[0139] The upper part 1 is the upper part of the mechanical connection interface in the liquid-phase charge shell, and the liquid-phase charge is located at the lower end of the upper part 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com