Alcohol fuel engine valve seat and manufacturing method thereof, alcohol fuel engine, automobile

An engine valve, alcohol fuel technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of valves and seat rings failing to lubricate, fast material decay at high temperature, and high engine combustion temperature. To achieve good high temperature mechanical properties, improve wear resistance, improve the effect of lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

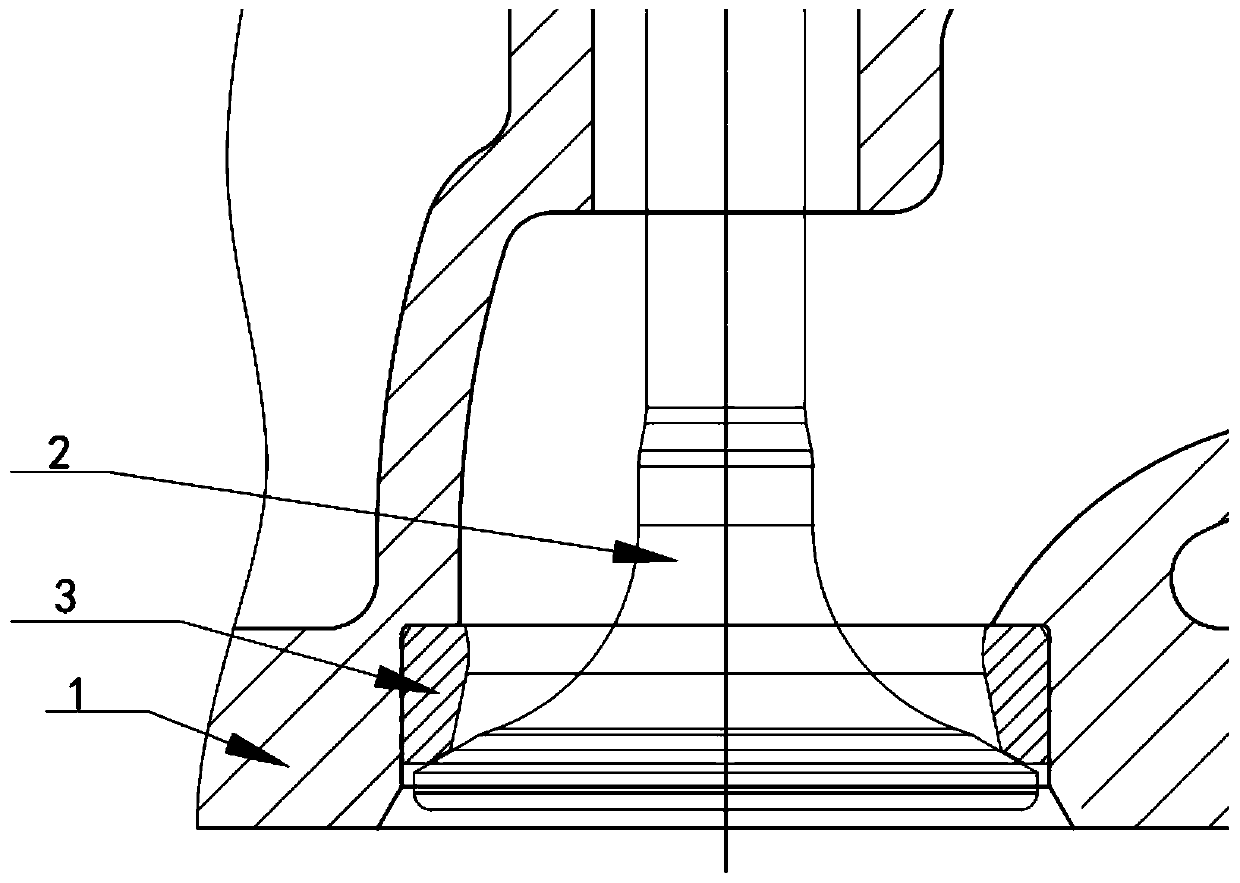

[0107] A valve seat for a methanol engine, including an intake valve seat and an exhaust valve seat; the chemical composition formulations of the intake valve seat and the exhaust valve seat are shown in Table 1.

[0108] The intake valve seat and the exhaust valve seat are independently compounded according to the chemical composition in Table 1, and after pressing, sintering and heat treatment, the intake valve seat and the exhaust valve seat are obtained.

[0109] Among them, the sintering temperature of the sintering process is 1150°C, and the sintering time is 80 minutes; the heating temperature of the heat treatment process is 900°C, the tempering temperature is 600°C, and the stabilization treatment temperature is 750°C.

Embodiment 2

[0111] A valve seat for a methanol engine, including an intake valve seat and an exhaust valve seat; the chemical composition formulations of the intake valve seat and the exhaust valve seat are shown in Table 1.

[0112] The intake valve seat and the exhaust valve seat are independently compounded according to the chemical composition in Table 1, and after pressing, sintering and heat treatment, the intake valve seat and the exhaust valve seat are obtained.

[0113] Among them, the sintering temperature of the sintering process is 1130°C, and the sintering time is 100min; the heating temperature of the heat treatment process is 880°C, the tempering temperature is 550°C, and the stabilization treatment temperature is 620°C.

Embodiment 3

[0115] A valve seat for a methanol engine, including an intake valve seat and an exhaust valve seat; the chemical composition formulations of the intake valve seat and the exhaust valve seat are shown in Table 1.

[0116] The intake valve seat and the exhaust valve seat are independently compounded according to the chemical composition in Table 1, and after pressing, sintering and heat treatment, the intake valve seat and the exhaust valve seat are obtained.

[0117] Among them, the sintering temperature of the sintering process is 1180°C, and the sintering time is 60 minutes; the heating temperature of the heat treatment process is 960°C, the tempering temperature is 640°C, and the stabilization treatment temperature is 880°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| crushing strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com