Singularized spherical-element conveying device applied to high-temperature gas cooled reactor

A high-temperature gas-cooled reactor and spherical element technology, which is applied in the field of reactor engineering to achieve the effects of easy replacement and maintenance and precise control of the rotor angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

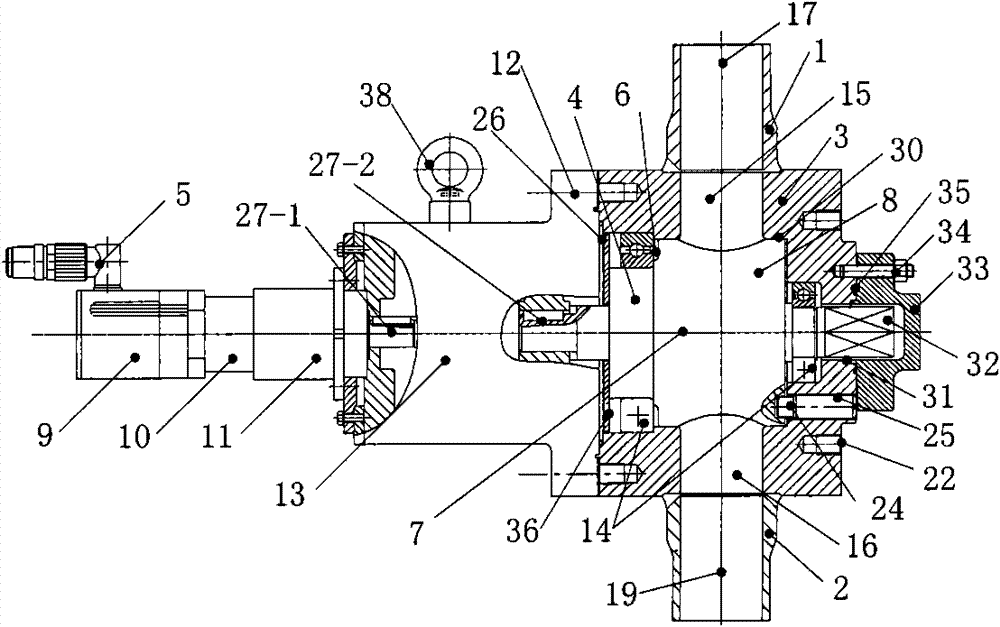

[0055] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

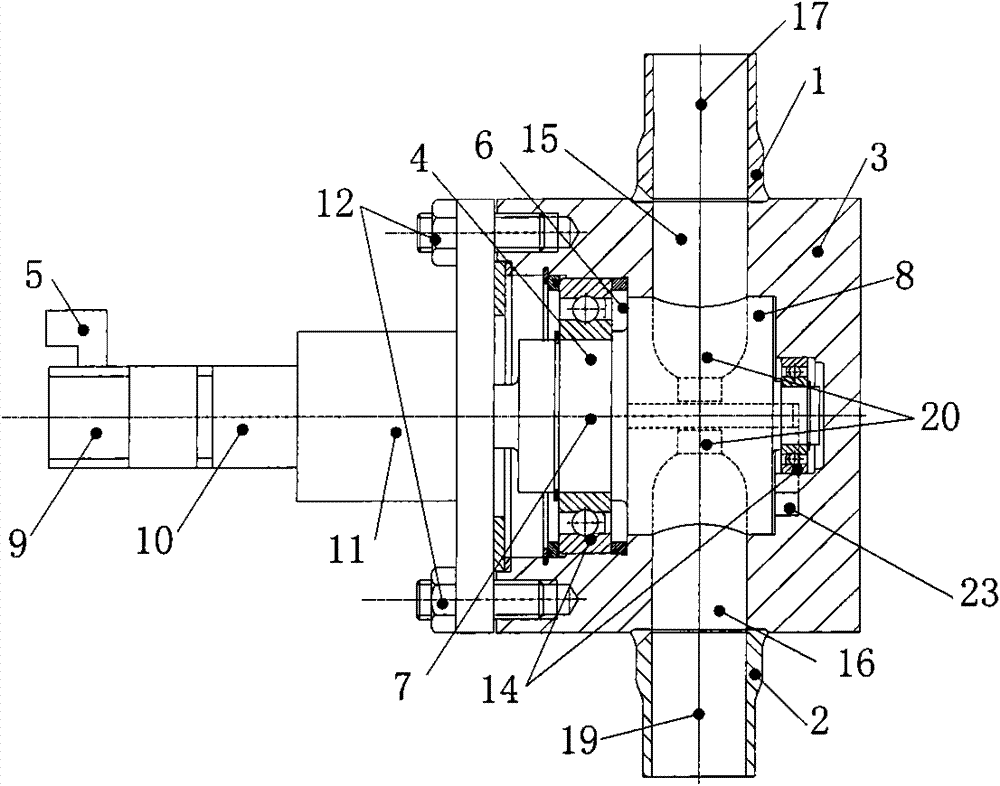

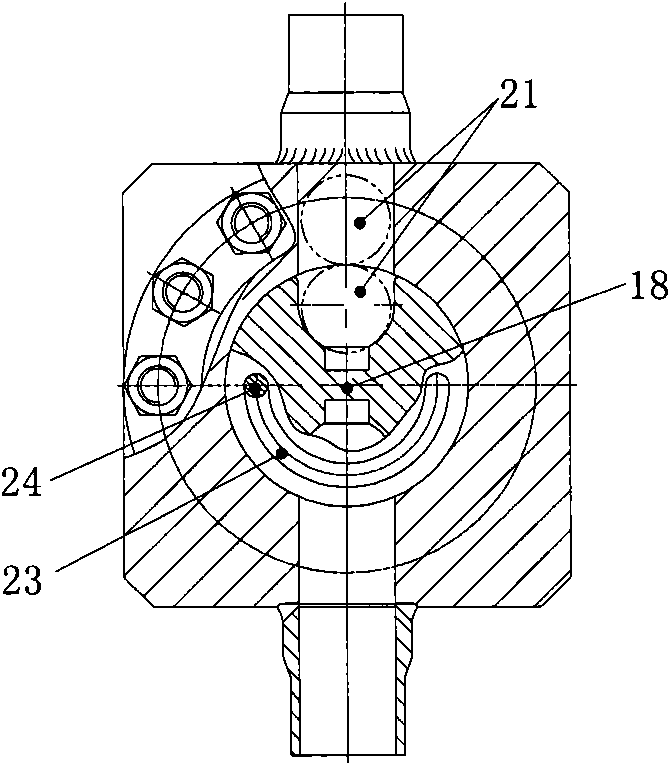

[0056] Such as Picture 1-1 with Figure 1-2 as shown, Picture 1-1 with Figure 1-2 It shows the basic structure of the high-temperature gas-cooled reactor spherical element pipeline simplification delivery device involved in the present invention.

[0057] Wherein, the working chamber of box body 3 comprises a cylindrical counterbore 6, and rotor 4 is supported in the cylindrical counterbore 6 of box body 3 through bearing 14, and the corresponding working section on the rotor 4 is round platform 8, and round platform 8 and cylinder The counterbores 6 have the same first axis 7 .

[0058] The drive part 5 includes an AC servo motor 9 and a planetary gear reducer 10 directly connected with it, and both the motor 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com