A kind of pipe jacking pit construction method

A construction method and technology of working pits, which are applied in the sewer pipeline system, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc., can solve the problems that cannot be directly reused, ring beams and I-beams are prone to damage, and high construction costs and other problems, to achieve the effect of reducing repeated construction costs, easy disassembly and assembly, and high reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

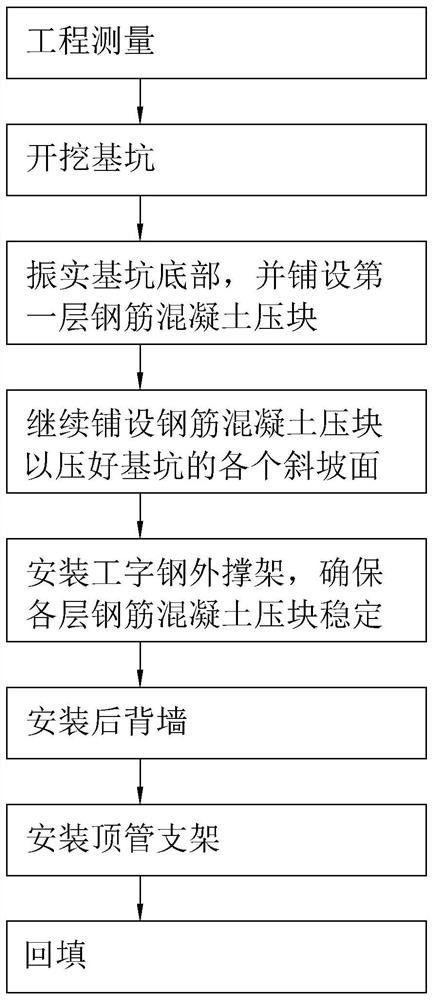

[0048] A construction method for a pipe jacking pit, such as figure 1 As shown, it specifically includes the following steps:

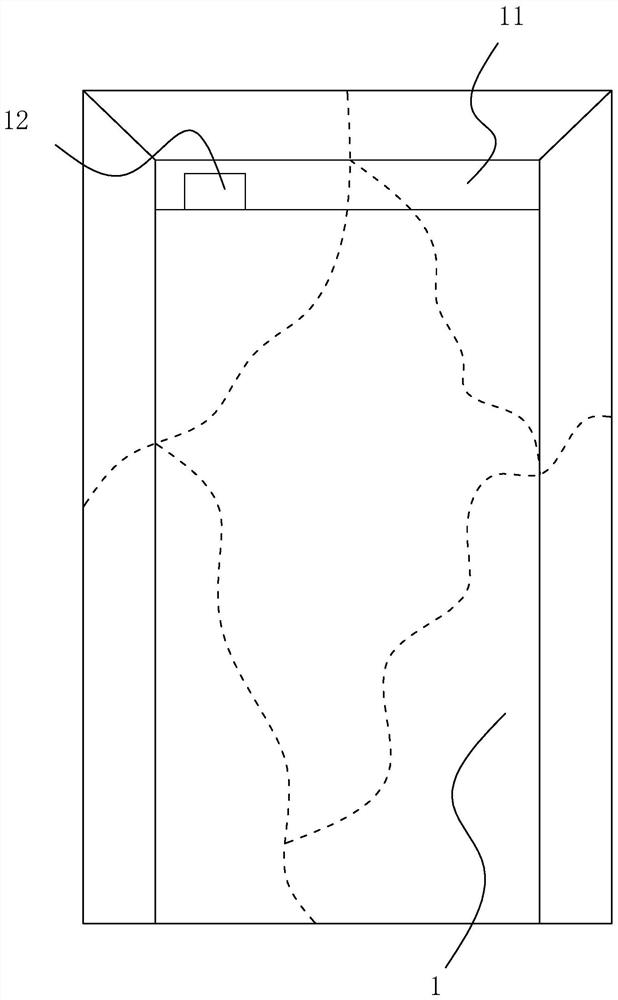

[0049] Step 1. Excavating the foundation pit 1, one short end of the foundation pit 1 is the pipe jacking end, and the two long sides of the foundation pit 1 and the pipe jacking end are arranged in a slope shape;

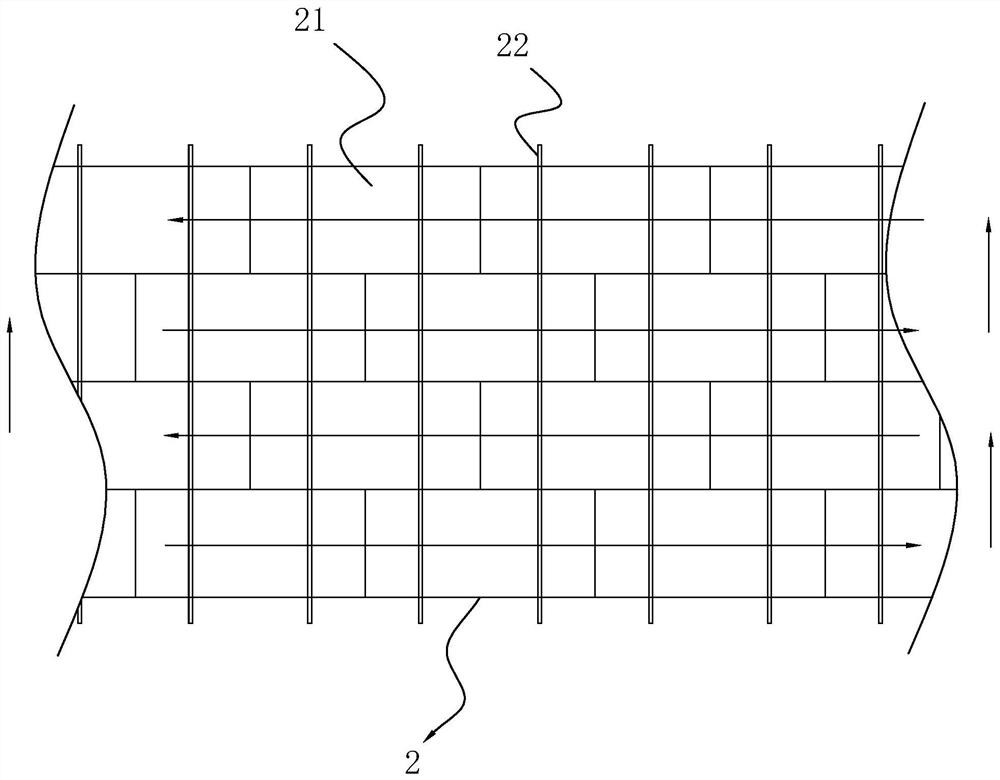

[0050] Step 2: Vibrate the edge of the bottom of the foundation pit 1, and put several pieces of reinforced concrete briquetting blocks 21 with a thickness of 18-25 cm into the foundation pit 1, and each piece of reinforced concrete briquetting blocks 21 is laid on the two sides of the foundation pit 1 respectively The bottom layer of the edge and the jacking end of the jacking pipe, and utilize anchor rods 23 to anchor each piece of reinforced concrete briquette 21 on each slope surface of the foundation pit 1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com