Method for preparing optical cables of optical fiber grating array for positioning and speed measurement of high-speed magnetic levitation train

A fiber grating array, magnetic levitation train technology, which is applied to devices using optical methods, cladding fibers, grating fibers, etc., can solve the problems of weak anti-interference ability, complex equipment design, low precision, etc., and achieve strong anti-electromagnetic interference ability. , The effect of reasonable design structure and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

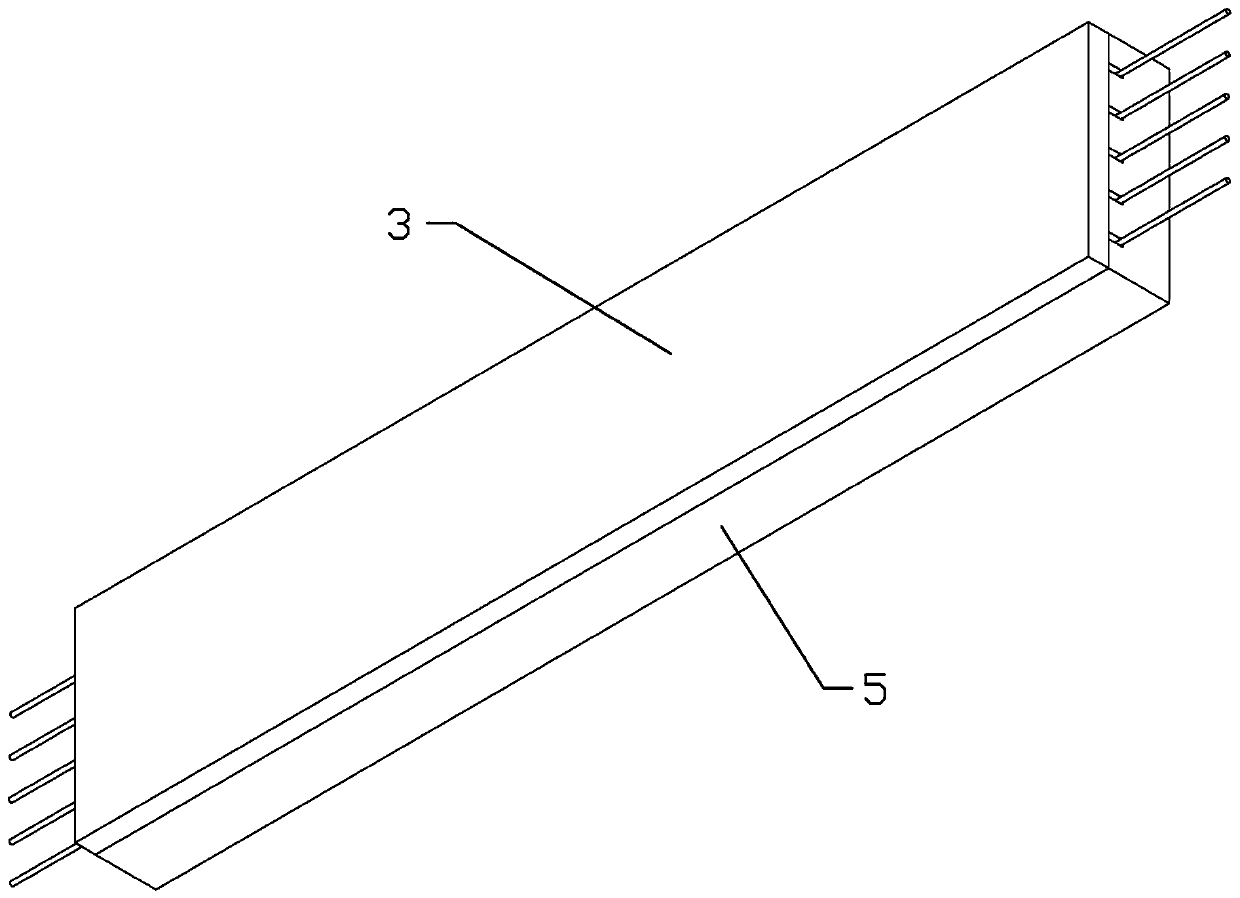

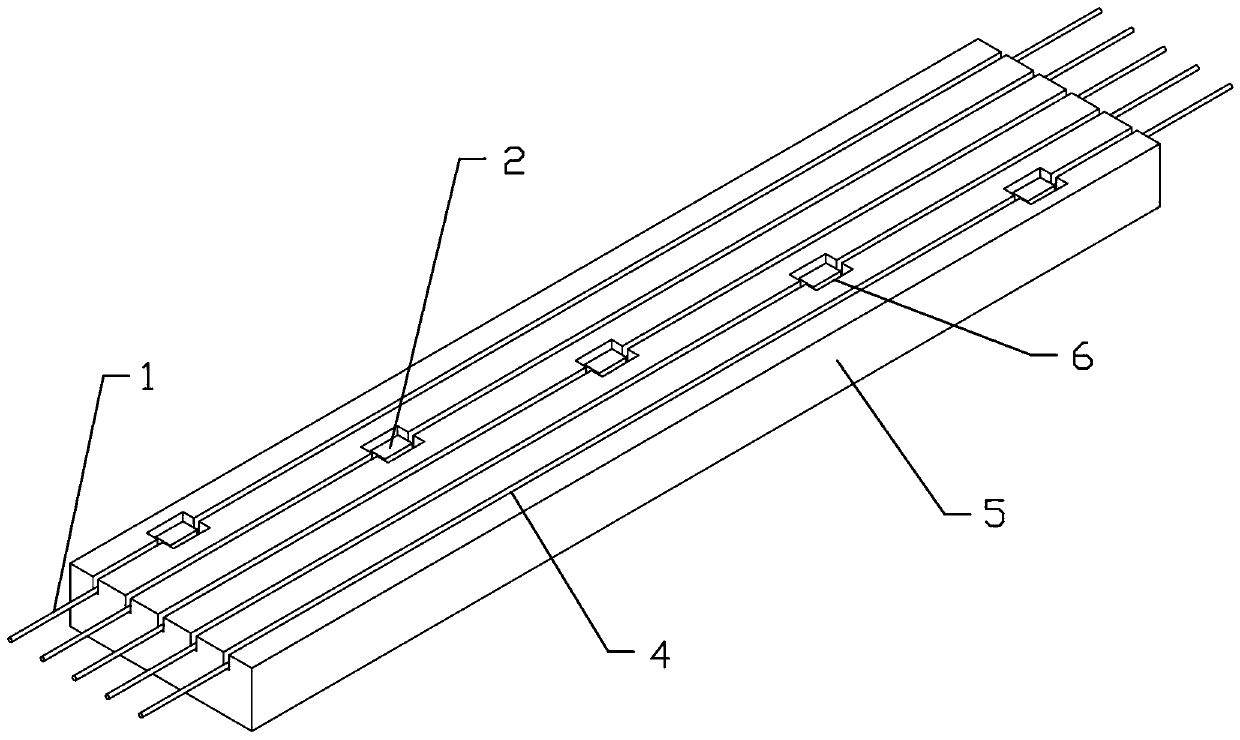

[0032] Such as figure 1 with figure 2 As shown, a method for preparing a fiber grating array optical cable used in the long-distance positioning and speed measurement system of a high-speed maglev train according to the present invention requires the following equipment and materials in the preparation process: an automatic glue dispenser with ultraviolet curing function, glue dispenser Loading platform, tension loading mechanism, linear material automatic retracting and unwinding equipment, stirring device, automatic cable forming equipment, ultraviolet curing glue, magnetic powder, flat polymer bottom belt 5, flat polymer flexible top belt 3, and fiber grating array 1,

[0033] Its preparation method comprises the following steps:

[0034] Step 1): Write the grating array 1 continuously in the same optical fiber. The length of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com