Measurement method of coal mill entrance ventilation quantity

A measurement method, coal mill technology, applied in the direction of grain processing, etc., can solve the problems of low precision and large deviation of the measurement results of the ventilation volume at the entrance of the coal mill, and achieve the effect of improving efficiency, small deviation and reasonable measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

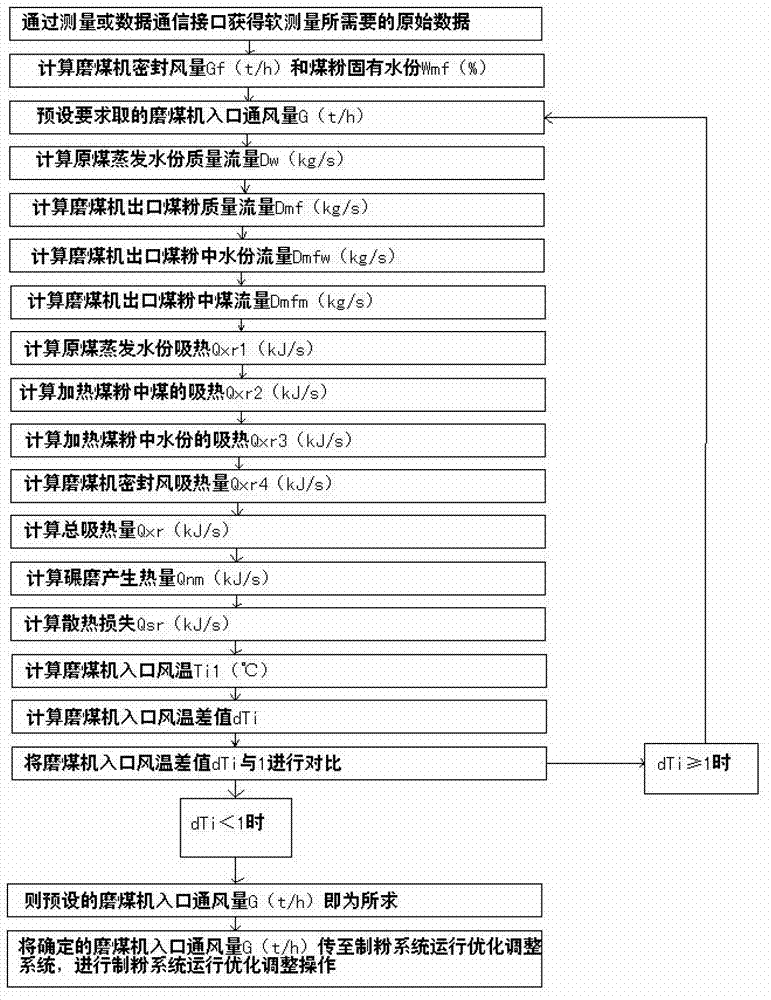

[0040] Aiming at the structural characteristics of the existing coal mill, the present invention proposes a method for indirectly measuring the air volume at the inlet of the coal mill according to the industrial analysis data and actual operating parameters of the coal mill for grinding coal, and adopting a heat balance method.

[0041] The method is implemented based on a corresponding intelligent measuring device, and the intelligent measuring device mainly includes a corresponding sensing and measuring device, a computing center (or computing unit) and a data storage unit.

[0042] Among them, the sensing and measuring device has several sensors, which are used to obtain various raw data required for measuring the air volume at the inlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com