Caffeine-containing fuming particle, preparation method thereof, and low-temperature heating incombustible product

A technology for fuming particles and caffeine, which is applied to tobacco, tobacco processing, and cigar manufacturing, etc., can solve the problems of easy leakage and inconvenience to carry, avoid inconvenient carrying, avoid tar and a large number of harmful compounds, The effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

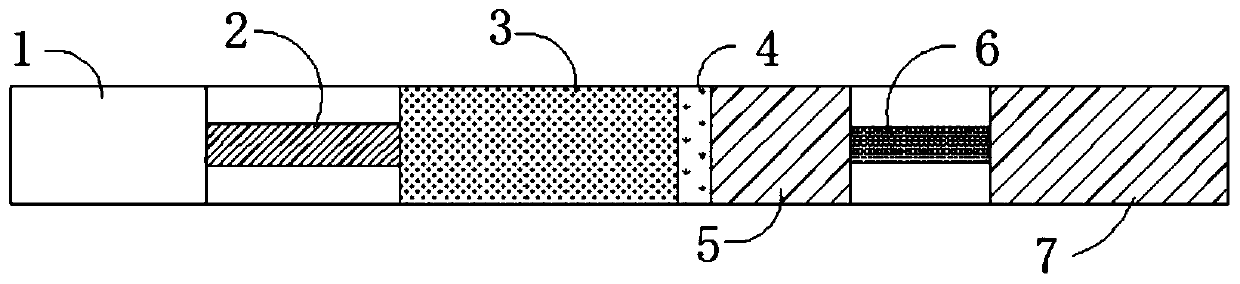

Image

Examples

Embodiment 1~5

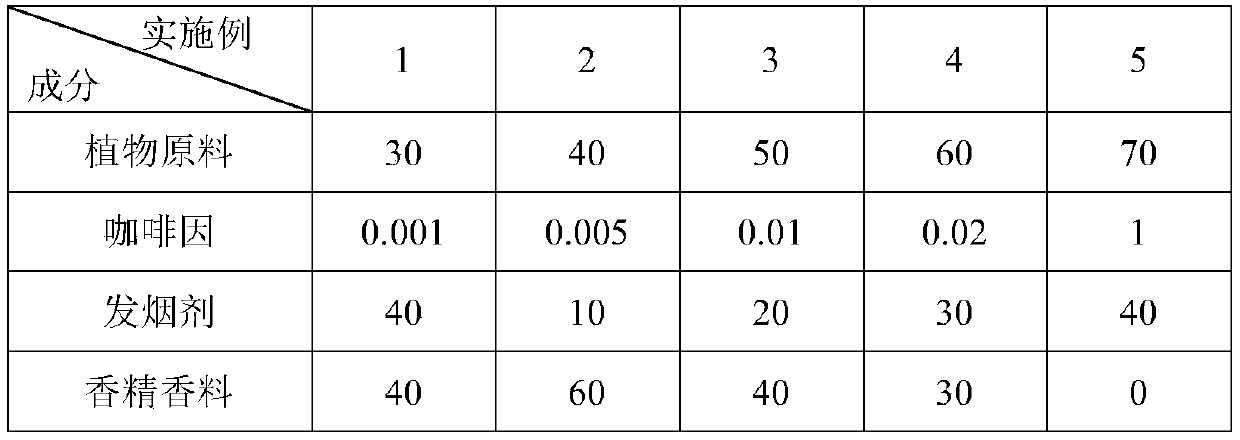

[0023] The smoking granules provided in Example 8 of the present invention are composed of the following components in parts by weight: 30-70 parts of plant materials, 10-40 parts of smoking agent, 0.001-1 part of caffeine-containing components, 30 parts of flavor and fragrance ~60 parts, each component is calculated by dry weight or pure substance. See Tables 1 to 3 for specific components and proportions. The unit in each table is g, and the caffeine-containing components in Tables 1 and 3 have been converted into caffeine weight.

[0024] Table 1 The total formula of fuming particles of each embodiment

[0025]

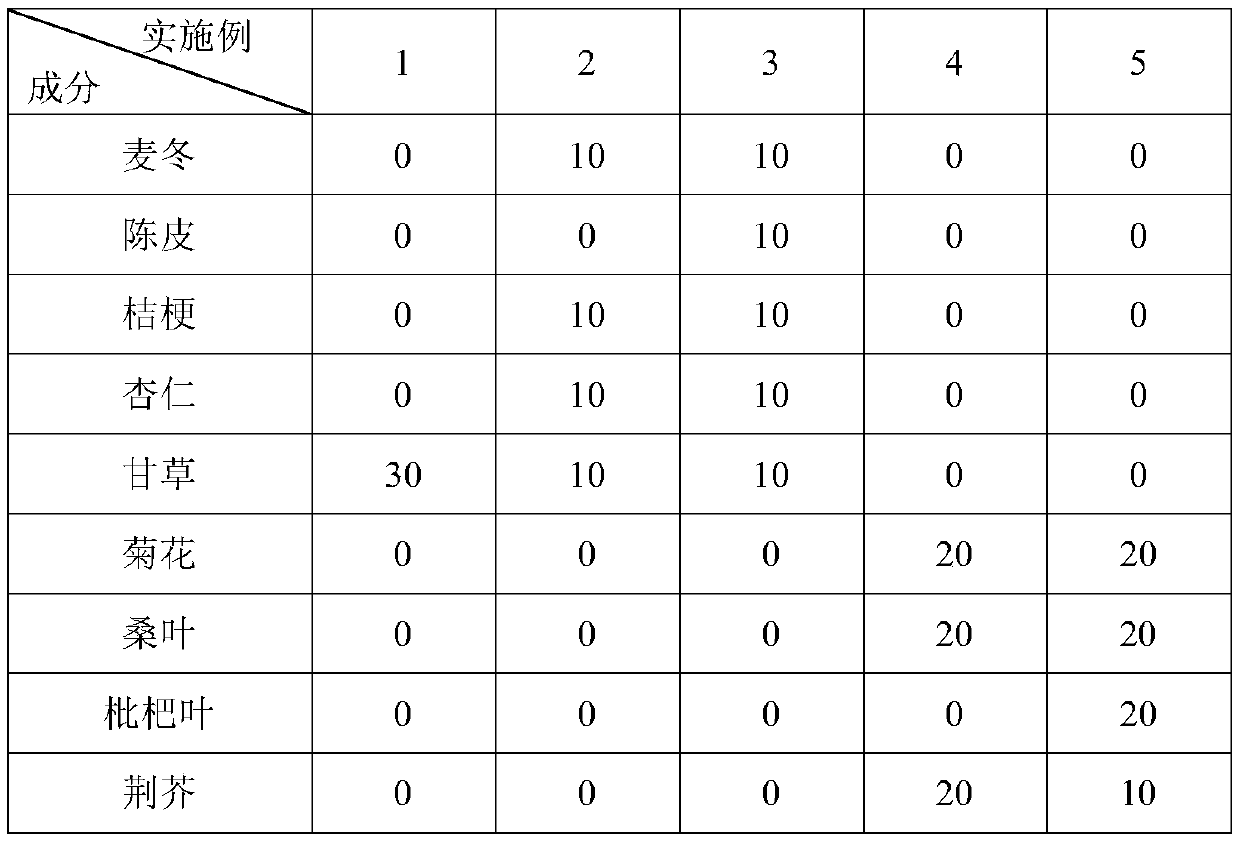

[0026] Table 2 each embodiment plant raw material formula table

[0027]

[0028] Table 3 each embodiment smoking agent, caffeine-containing component and other component formulation table

[0029]

Embodiment 6

[0031] This embodiment provides a method for preparing any fuming particles in Examples 1 to 3, the steps are as follows: crush each plant material into 20 to 80 mesh particles, and then mix caffeine-containing components, fuming agents, flavors and fragrances After mixing evenly, spray it on the surface of the above particles to prepare smoke particles. The particle size distribution of the produced fuming particles is: 20-40 mesh not less than 70wt%, 40-60 mesh not more than 20wt%, 60-80 mesh not more than 10wt%.

Embodiment 7

[0033] This example provides the preparation method of the fuming granules in Example 4 or 5, the steps are as follows: grind each plant raw material into fine powder, and mix them evenly with the smoke-generating agent and essence and fragrance (Example 5 does not add essence and fragrance) , and then use swing granulation method, boiling granulation method, spray drying granulation method, crushing granulation method and other methods to prepare semi-finished granules, and finally spray caffeine-containing components on the surface of semi-finished granules to prepare fuming granules. The particle size distribution of the prepared fuming particles is: 20-40 mesh not less than 70wt%, 40-60 mesh not more than 20wt%, 60-80 mesh not more than 10wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com