Disinfectant filtering-sterilizing and cleaning system capable of performing CIP/SIP on line

A sterilization system and disinfectant technology, applied in filtration, disinfection, chemical/physical processes, etc., can solve problems such as affecting efficiency, contamination, complicated operation, etc., to speed up filtration, avoid easy leakage, and reduce losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

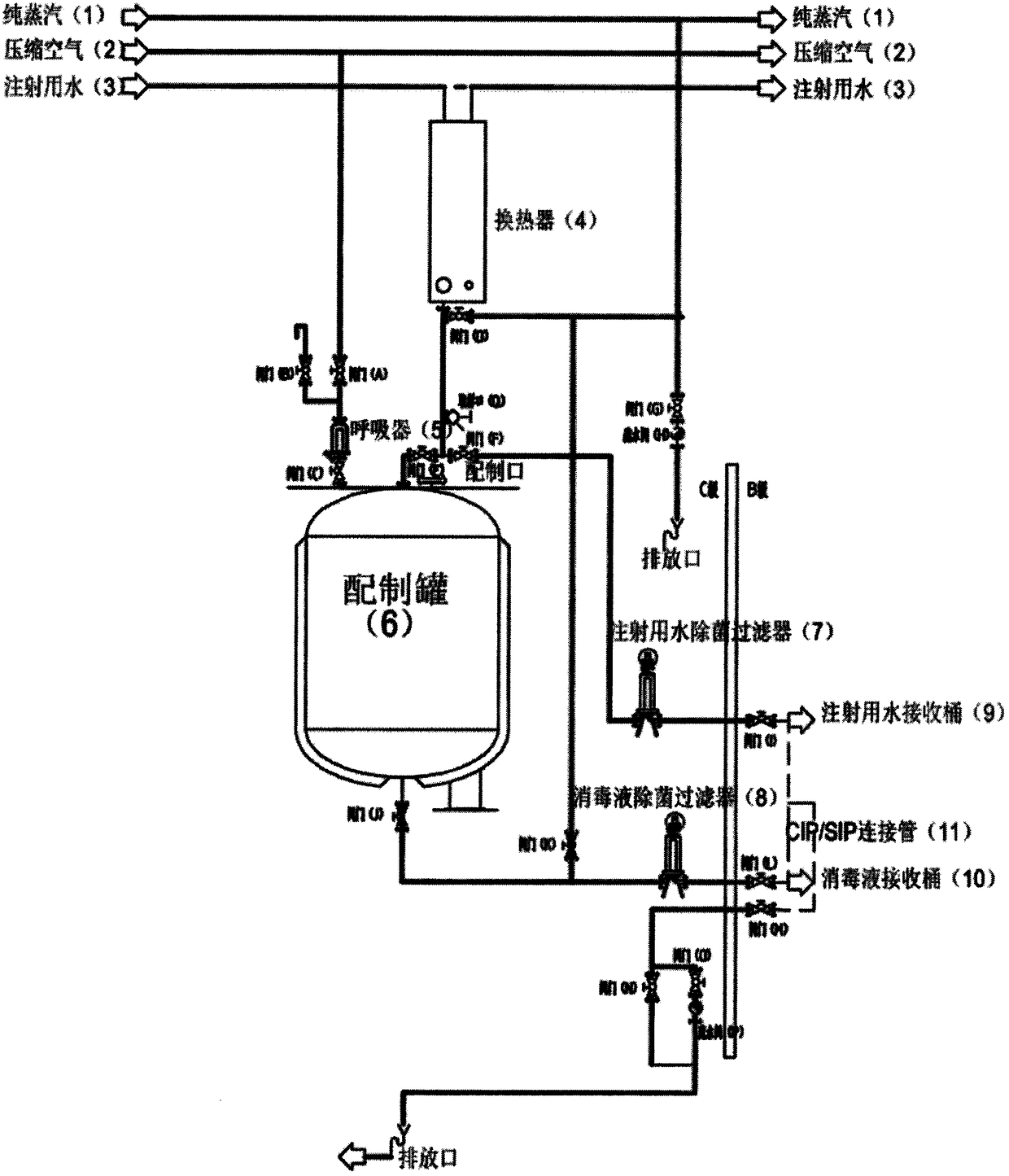

[0024] As shown in the figure, connect the components of the system, including: (1) pure steam, (2) compressed air, (3) water for injection, (4) heat exchanger, (5) respirator, (6) preparation tank , (7) Sterilization filter for injection water, (8) Sterilization filter for disinfectant, (9) receiving barrel, (10) receiving barrel, (11) CIP / SIP connecting pipe, (12) compressed air pressure reducing valve A, (13) valve B, (14) valve C, (15) valve D, (16) valve E, (17) valve F, (18) valve G, (19) trap H, (20) valve I , (21) valve J, (22) valve K, (23) valve L, (24) valve M, (25) valve N, (26) valve O, (27) trap P, (28) sampling port Q .

Embodiment 2

[0025] Example 2 Filtration of water for injection:

[0026] Turn on the heat exchanger (4), reduce the temperature of the water for injection to the required temperature, open the valve (D), valve (F), and valve (I). After the water for injection passes through the water for injection sterilization filter (7), it is filtered to Water for injection receiving barrel (9).

Embodiment 3

[0027] Example 3 Filtration of disinfectant solution:

[0028] The disinfectant is prepared and put into the preparation tank, or after the disinfectant is added to the preparation tank, a certain amount of water for injection is added in proportion to prepare. After preparing the disinfectant, open the compressed air pressure reducing valve (A), valve (C), and valve (L). The disinfectant is driven by the compressed air through the disinfectant sterilization filter (8) and then filtered to the disinfectant. Receive bucket (10).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com