Intelligent high-speed motorized spindle realizing integration of multi-parameter detection

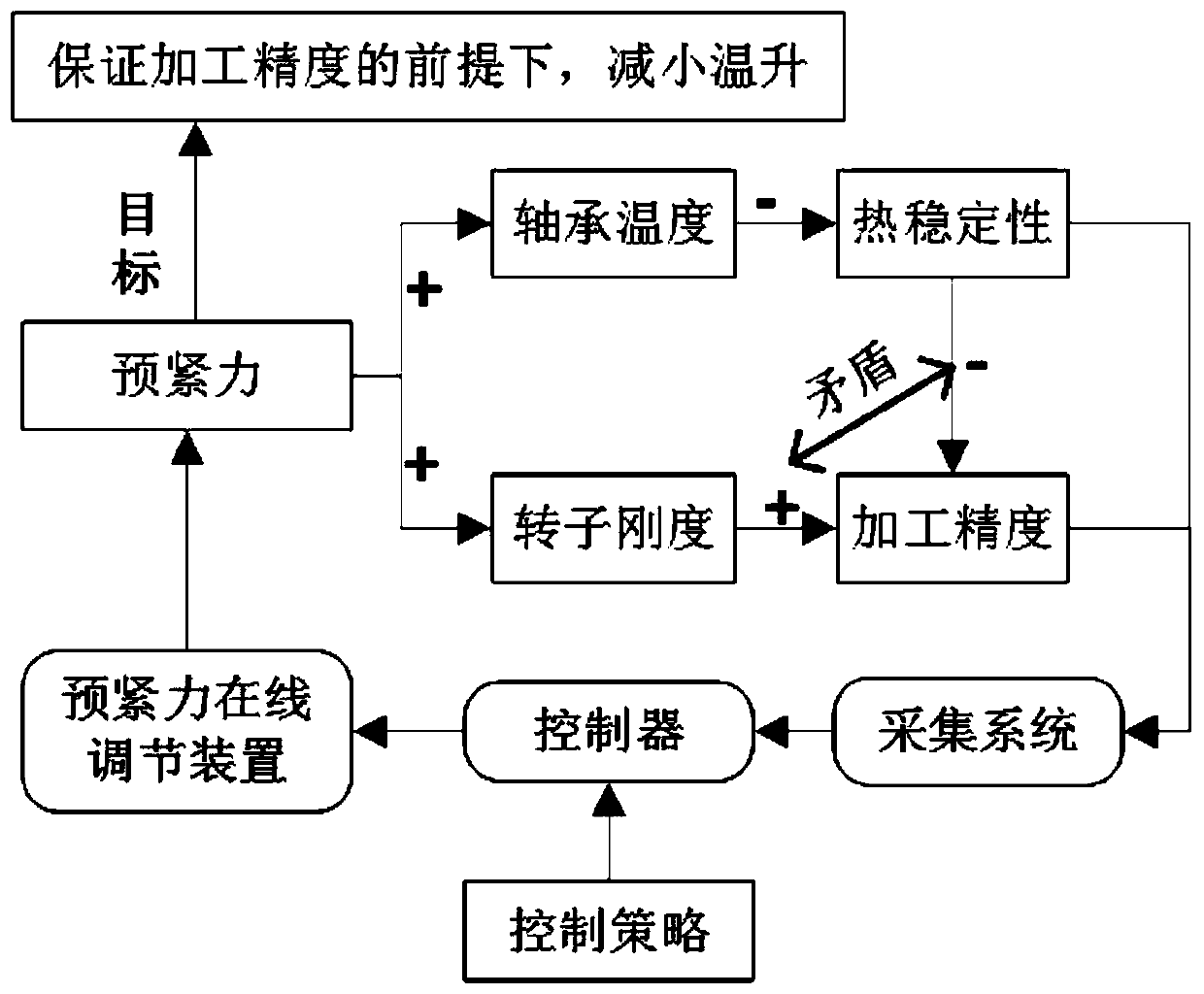

A high-speed electric spindle and multi-parameter technology, which is applied in the direction of large-scale fixed members, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problem of single detection sensor of operating state parameters, low degree of integration, and adjustment of bearing pretightening force And other problems, to achieve the effect of improving dynamic performance, reducing temperature rise, and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

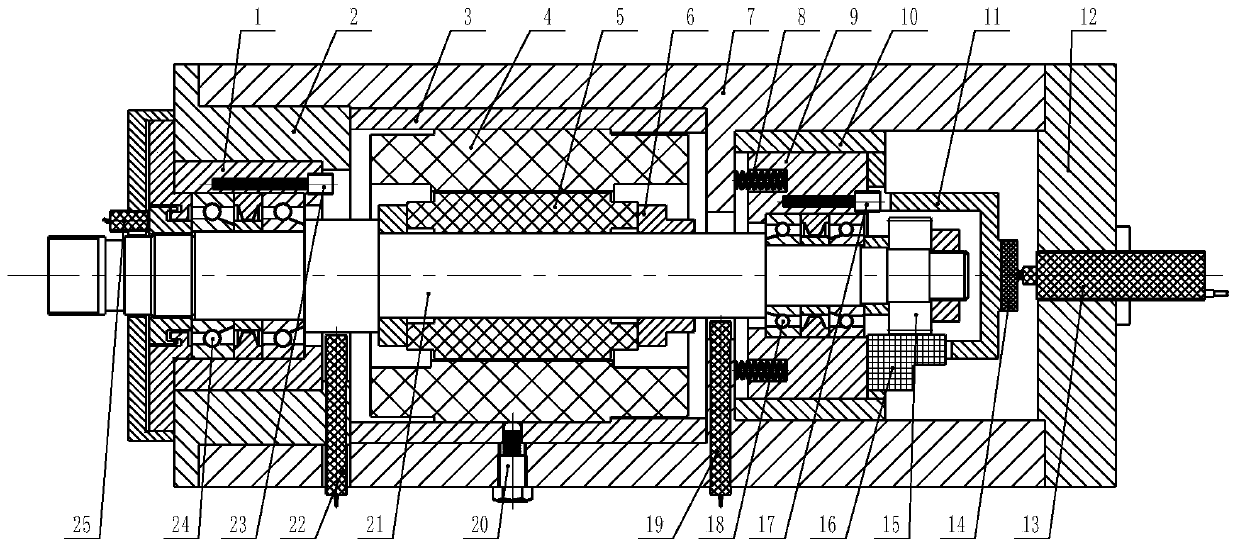

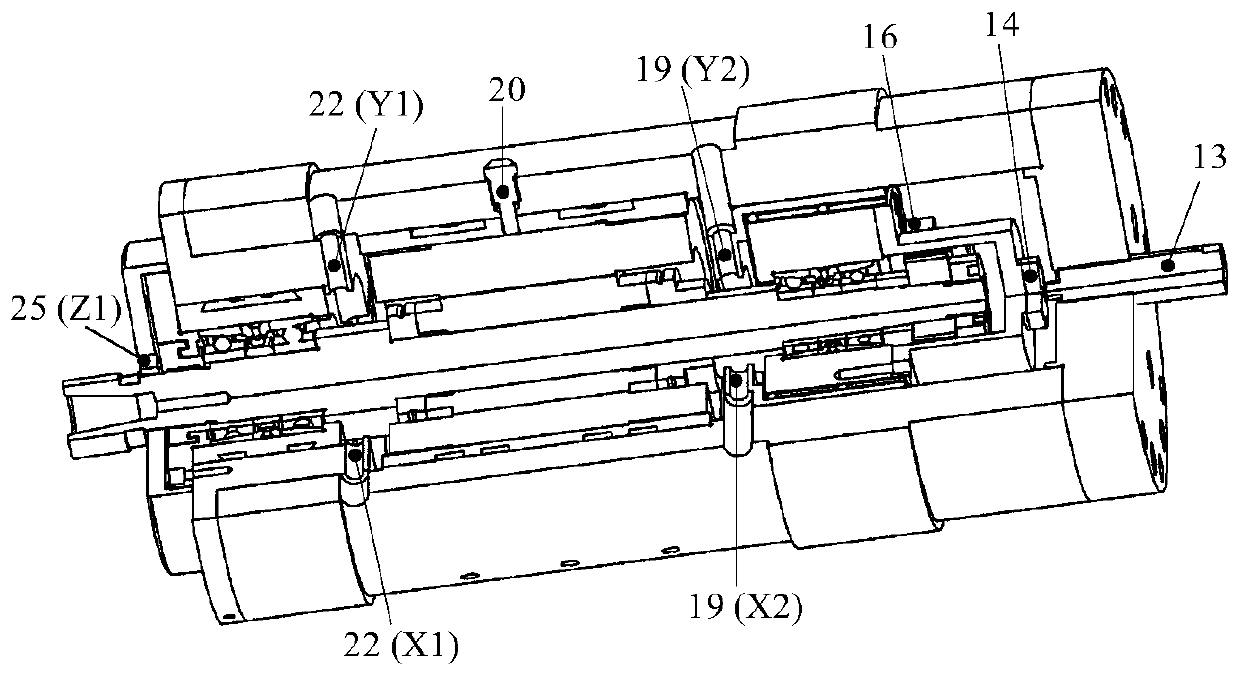

[0021] Such as figure 1 The shown intelligent high-speed electric spindle integrated with multi-parameter detection includes a rotating shaft 21 arranged in the casing 7, a stator 4 fixed on the inner wall of the casing 7, and a rotor 5 installed on the rotating shaft 21. The stator 4. Cooperate with the rotor 5 to realize the rotation of the rotating shaft 21. Both sides of the rotor 5 are provided with a dynamic balance ring 6, which is press-fitted on the rotating shaft 21 and is close to both sides of the iron core of the rotor 5 for calibrating the dynamic Balance function; rotating shaft 21 is supported by front bearing 24 and rear bearing 18 installed at its two ends; Bearing 18 is installed in rear bearing seat 9, and rear bearing seat 9 is installed in the rear end of housing 7; There is an annular mounting platform integrally formed with the inner side wall of the housing 7 .

[0022] A temperature sensing unit for collecting the temperature rise characteristics of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com