Carrying, loading and unloading mechanism of long steel rail transport cart unit

A technology of loading and unloading mechanism and long rails, which is applied to the transportation of passenger cars, transportation and packaging, loading and unloading of railway vehicles, etc. It can solve the problems of low automation, low operation efficiency and complicated operation, and achieve strong integrity, high operation efficiency, Simple effect of function switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0036] In conjunction with the accompanying drawings.

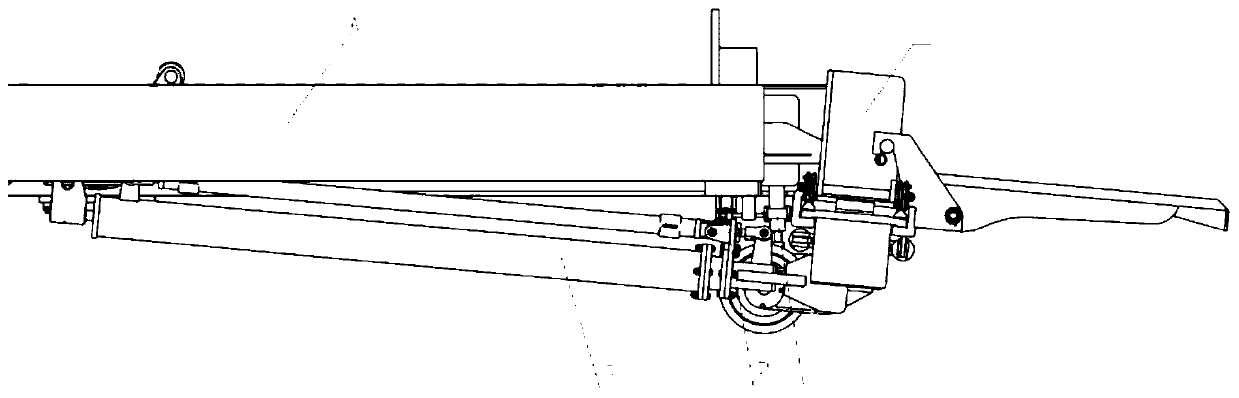

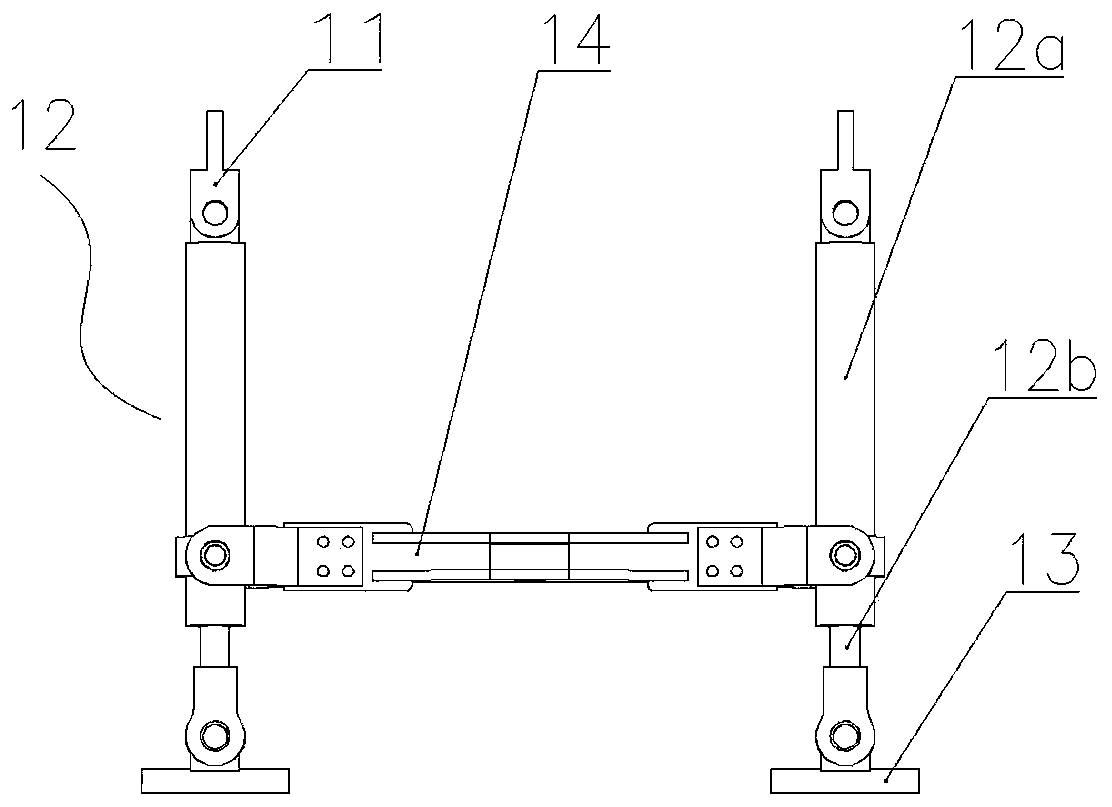

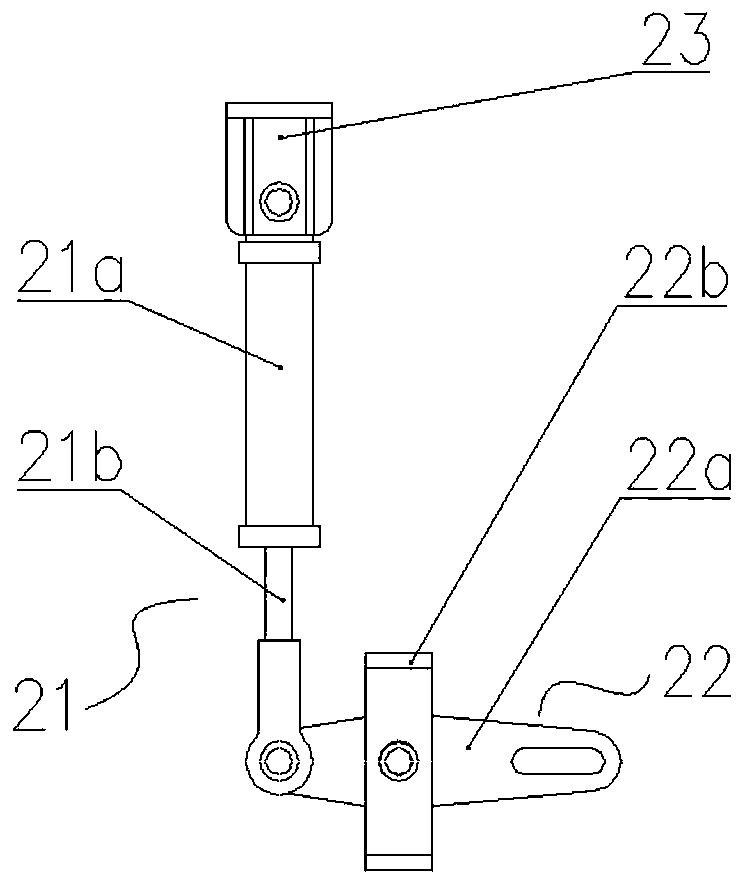

[0037] The loading and unloading mechanism of the long rail transport wagon group includes the long rail loading and unloading vehicle A, and the loading and unloading mechanism also includes the working trolley B, the connecting mechanism between the working trolley B and the loading and unloading trolley A, and the driving and guiding mechanism 3;

[0038] The work trolley B includes: a work platform, a rail release device B4 set on the work platform, and a trolley roller B5 that supports the work trolley B and moves with the loading and unloading tro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com