Concrete pouring method for deep foundation pit

A concrete and deep foundation pit technology, applied in the field of concrete pouring, can solve the problems of inconvenient movement of hoisting equipment, reduce concrete pouring effect, concrete waste, etc., improve pouring effect and pouring efficiency, avoid concrete segregation and layering, and ensure uniformity The effect of sex and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

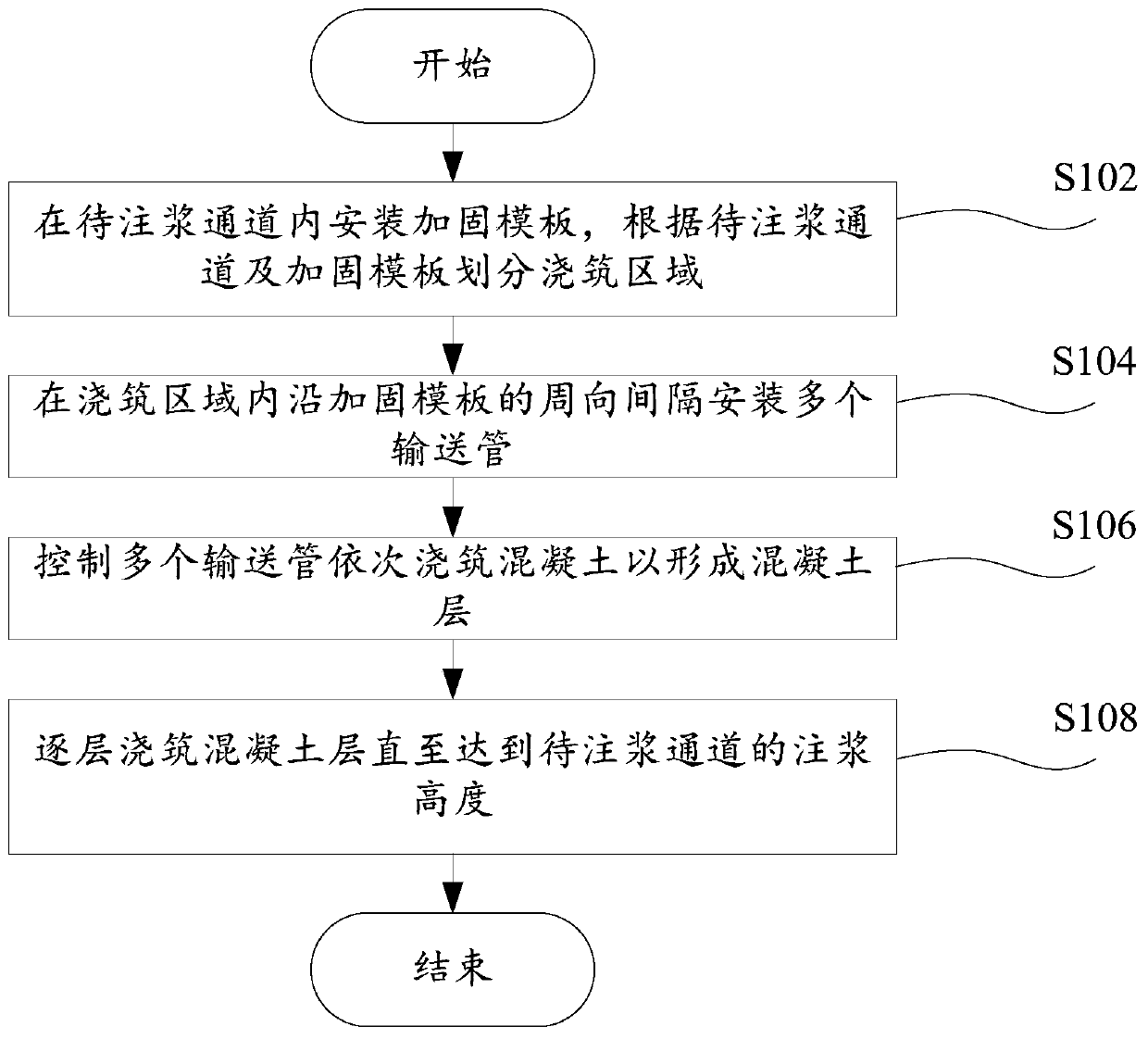

[0052] figure 1 A schematic flow diagram of the deep foundation pit concrete pouring method of the first embodiment of the present invention is shown, wherein the deep foundation pit concrete pouring method includes:

[0053] S102, installing a reinforcement formwork in the channel to be grouted, and dividing the pouring area according to the channel to be grouted and the reinforcement formwork;

[0054] S104, installing a plurality of conveying pipes at intervals along the circumference of the reinforced formwork in the pouring area;

[0055] S106, controlling a plurality of conveying pipes to sequentially pour concrete to form a concrete layer;

[0056] S108, pouring concrete layers layer by layer until reaching the grouting height of the channel to be grouted.

[0057] In detail, a reinforcement formwork is installed in the passage to be grouted (such as the reinforcement formwork is configured as a cylindrical structure), and the pouring area is divided according to the ...

Embodiment 2

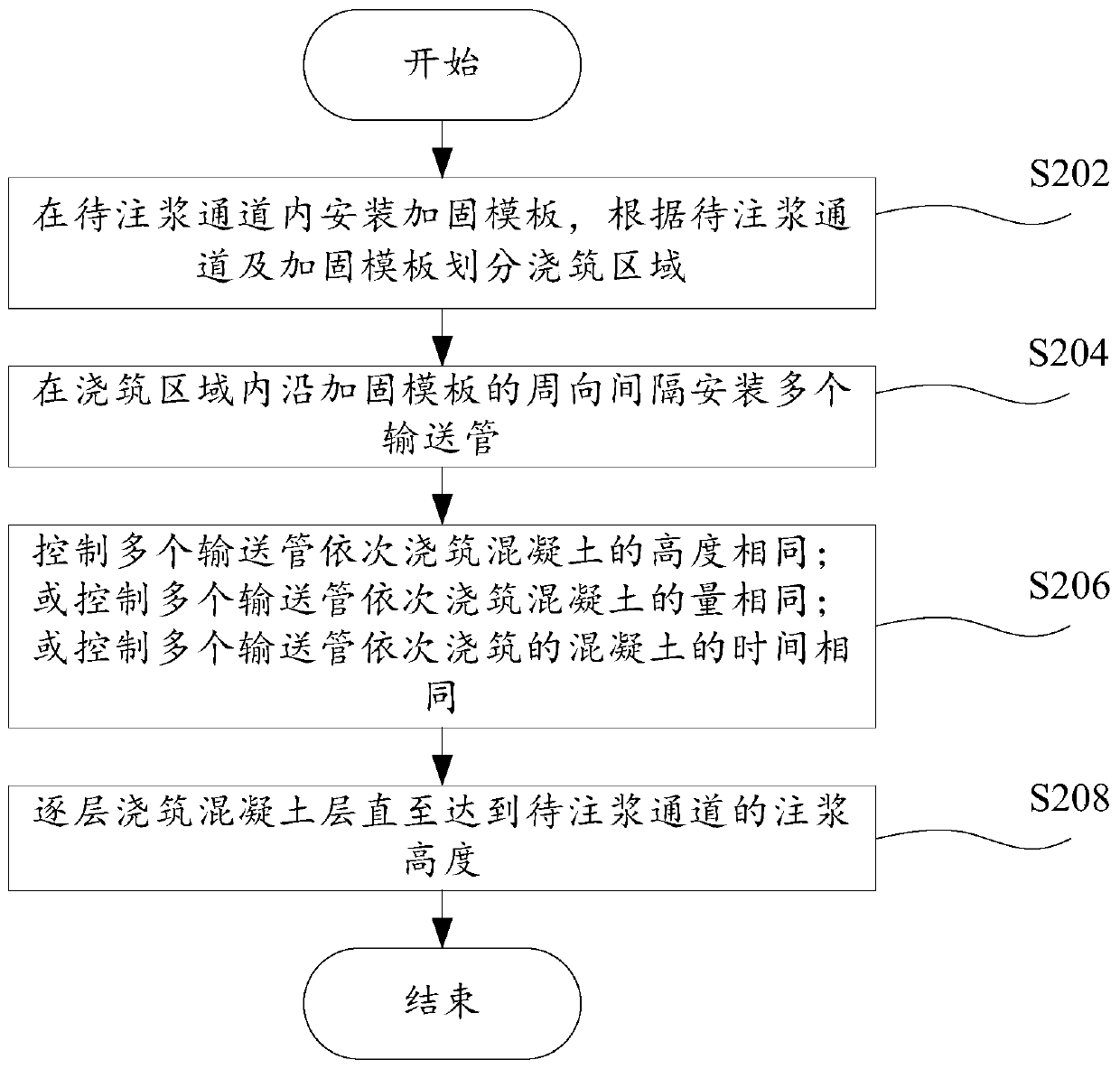

[0059] figure 2 Show the schematic flow chart of the deep foundation pit concrete pouring method of the second embodiment of the present invention, wherein, the deep foundation pit concrete pouring method comprises:

[0060] S202, installing a reinforcement formwork in the channel to be grouted, and dividing the pouring area according to the channel to be grouted and the reinforcement formwork;

[0061] S204, installing a plurality of conveying pipes at intervals along the circumference of the reinforced formwork in the pouring area;

[0062] S206, control multiple delivery pipes to pour concrete at the same height sequentially; or control multiple delivery pipes to sequentially pour concrete at the same amount; or control multiple delivery pipes to sequentially pour concrete at the same time;

[0063] S208, pouring concrete layers layer by layer until reaching the grouting height of the channel to be grouted.

[0064] In detail, since the shape of the channel to be grouted...

Embodiment 3

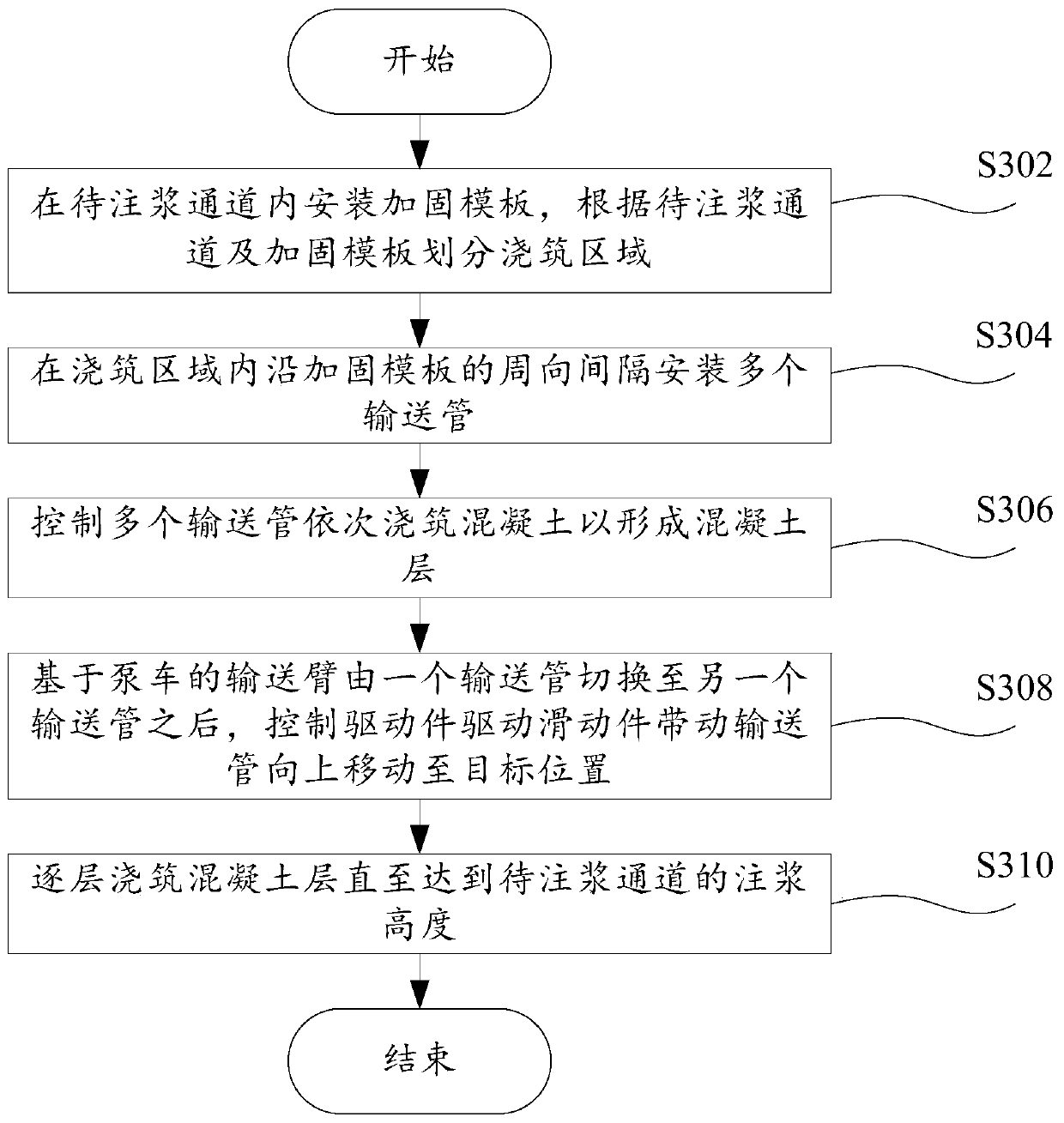

[0067] image 3 A schematic flow chart of the deep foundation pit concrete pouring method of the third embodiment of the present invention is shown, wherein the deep foundation pit concrete pouring method includes:

[0068] S302, installing a reinforcement formwork in the channel to be grouted, and dividing the pouring area according to the channel to be grouted and the reinforcement formwork;

[0069] S304, installing a plurality of conveying pipes at intervals along the circumference of the reinforced formwork in the pouring area;

[0070] S306, controlling a plurality of conveying pipes to sequentially pour concrete to form a concrete layer;

[0071] S308, after the delivery arm of the pump truck is switched from one delivery pipe to another delivery pipe, the driving part is controlled to drive the sliding part to drive the delivery pipe to move upward to the target position;

[0072] S310, pouring concrete layers layer by layer until reaching the grouting height of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com