Horizontal joint connecting node of assembled prefabricated structure wallboard unit

A technology of prefabricated structures and connecting nodes, which is applied in the direction of walls, building components, building structures, etc., can solve problems such as the construction technology and procedures are not simple enough, the section steel has no description, and the principles of earthquake-resistant structures have not been implemented.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

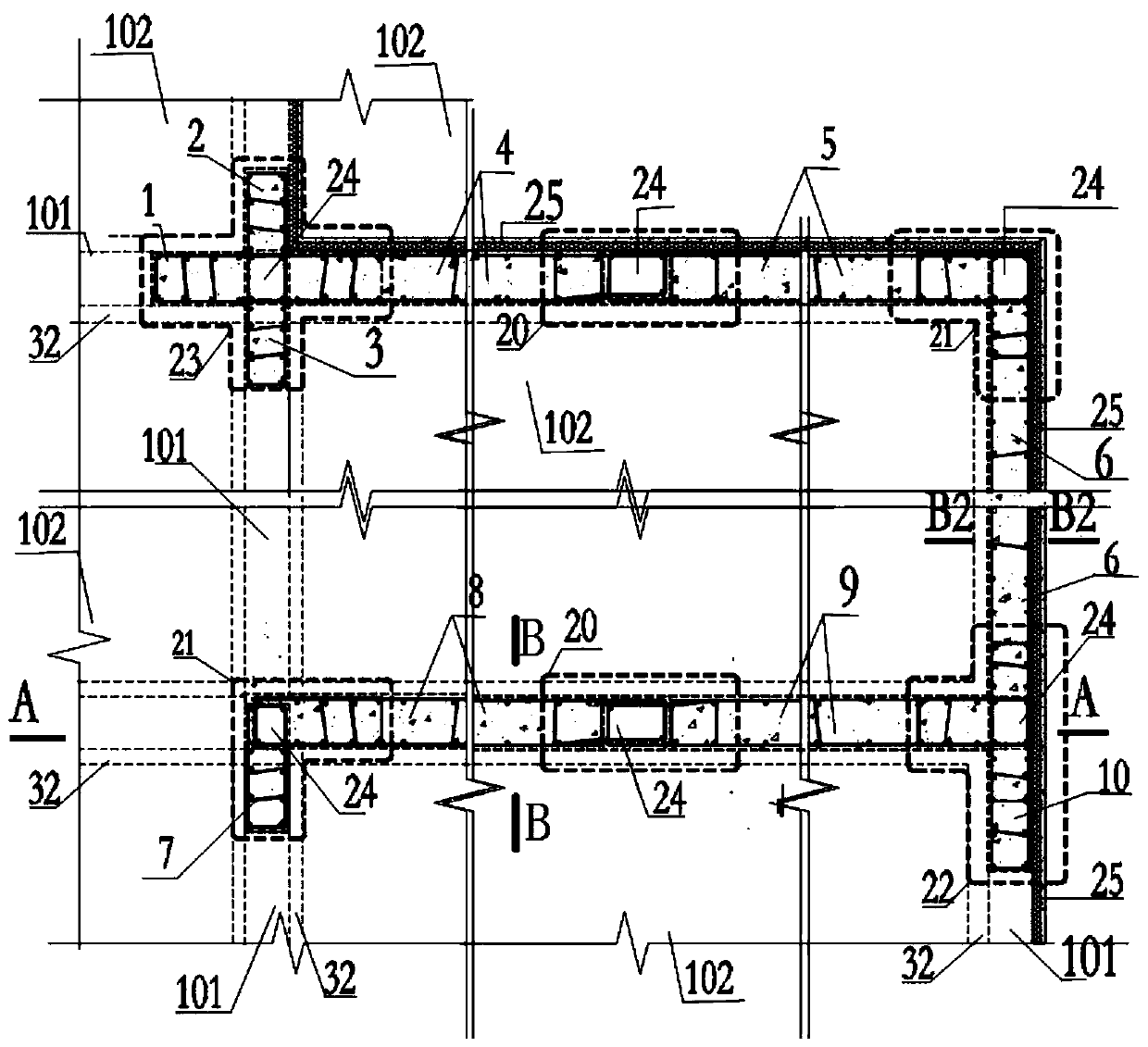

[0116] see figure 1 , the schematic diagram of the prefabricated structure wall panel unit of the present invention and its connection node implementation: wherein there are prefabricated structure wall panel unit 1-10, vertical seam connection node 20-23, horizontal groove 32 of horizontal seam connection node, six It is vertically connected to the cavity 24 ; it also includes the related connected horizontal components - the prefabricated floor slab 102 and the prefabricated composite beam 101 .

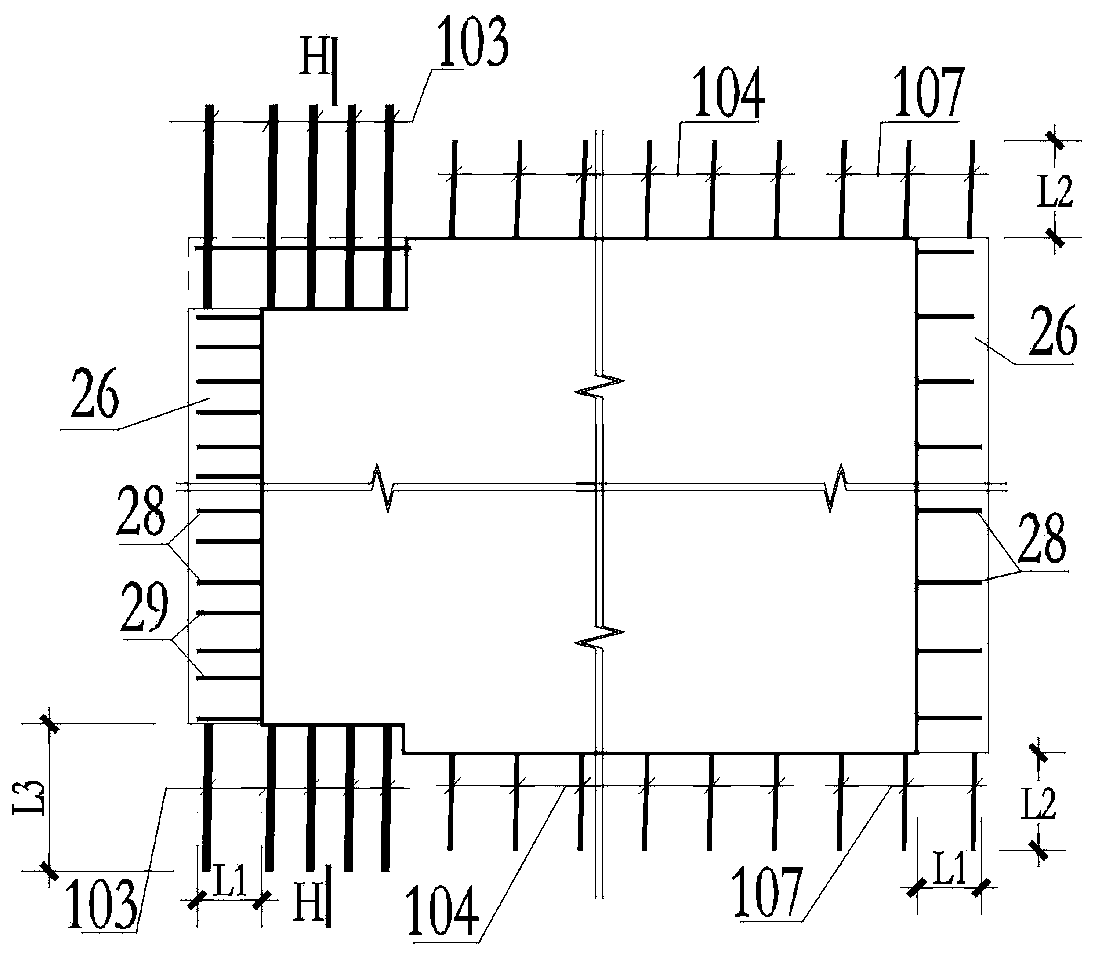

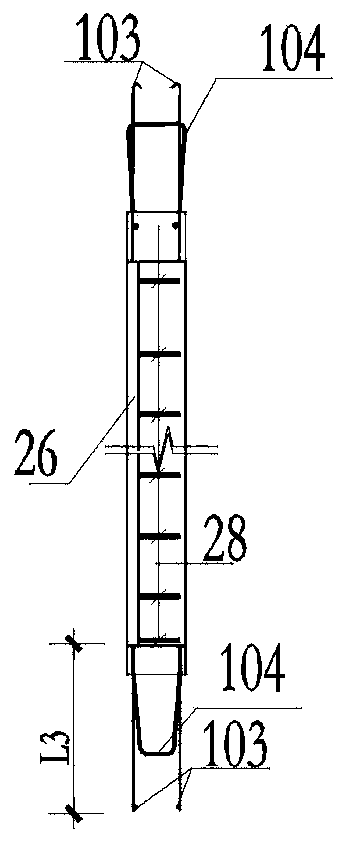

[0117] see Figure 2-8 , the figure starts with figure 1 The prefabricated structural wall panel unit 8 is drawn as a case. The prefabricated structural wall panel unit is an ordinary prefabricated shear wall, which is a prefabricated component with two surfaces, four joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com