Rigid splicing structure, assembly-type wall and manufacturing and mounting method

A prefabricated and rigid technology, applied in the direction of walls, building components, building structures, etc., can solve problems such as complex installation, achieve quick installation, improve assembly efficiency, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

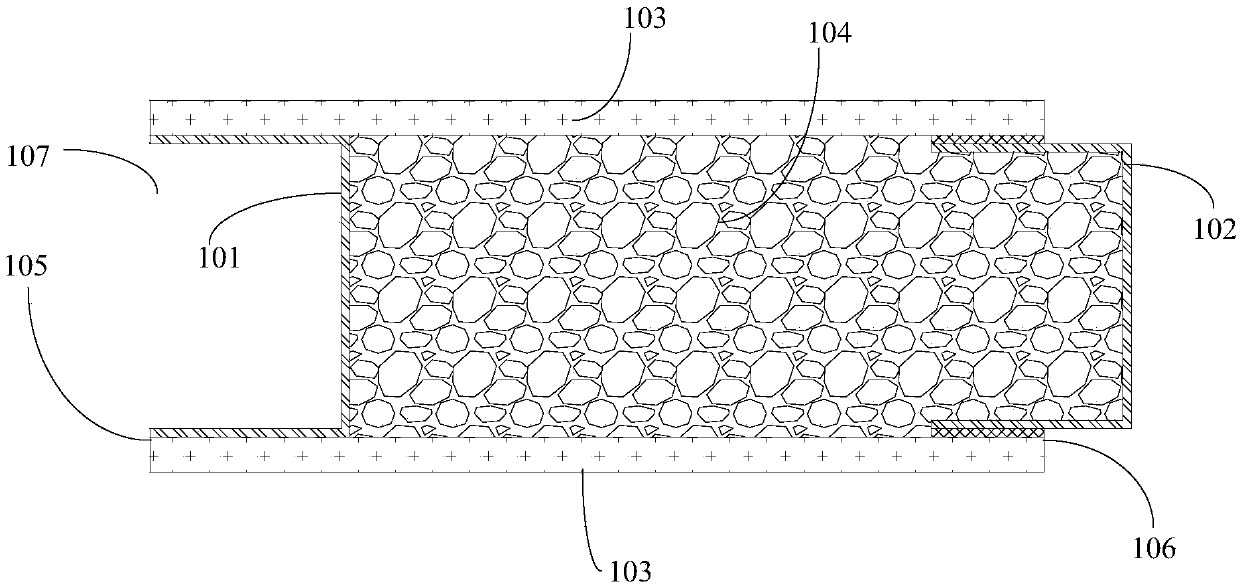

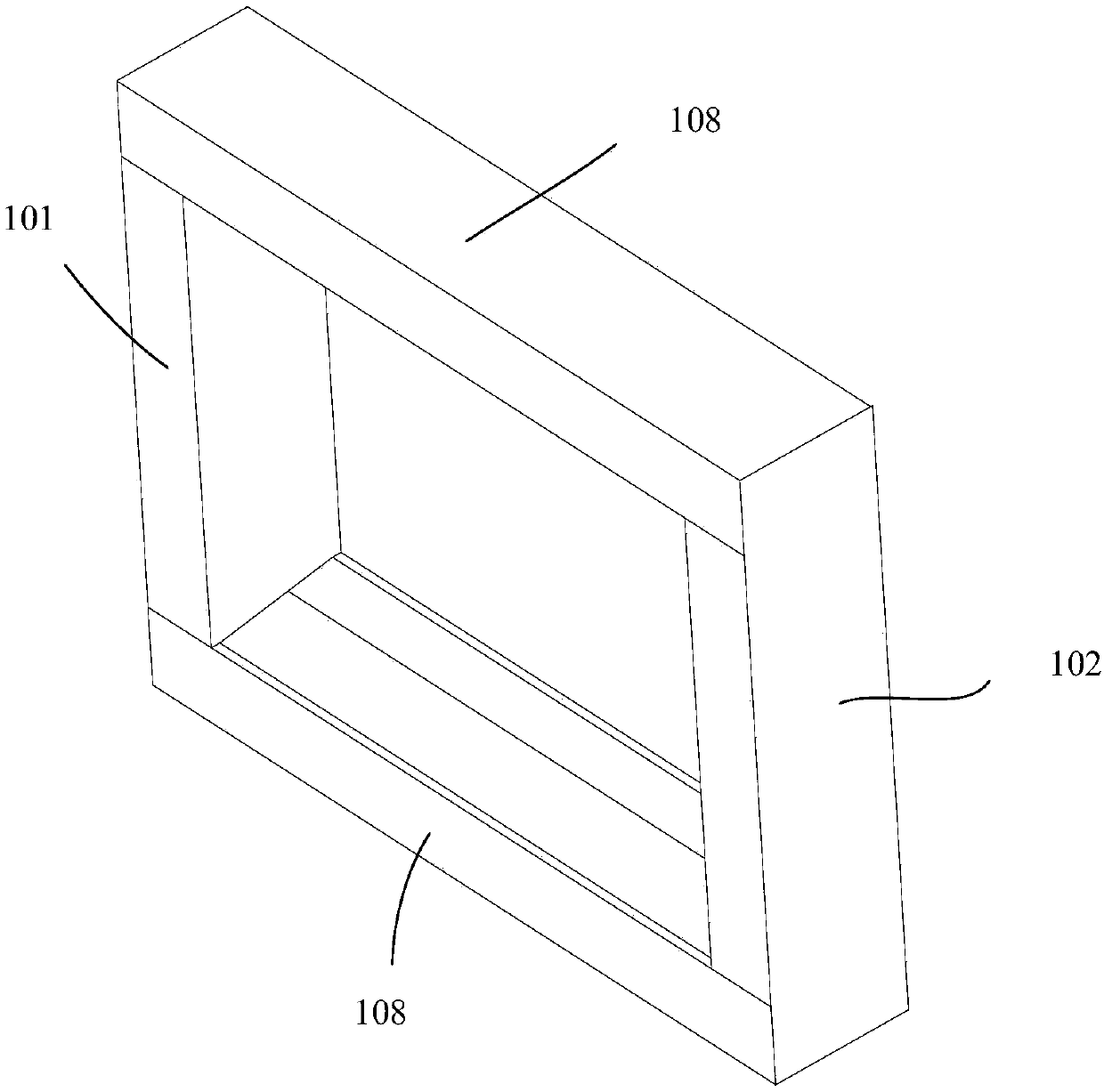

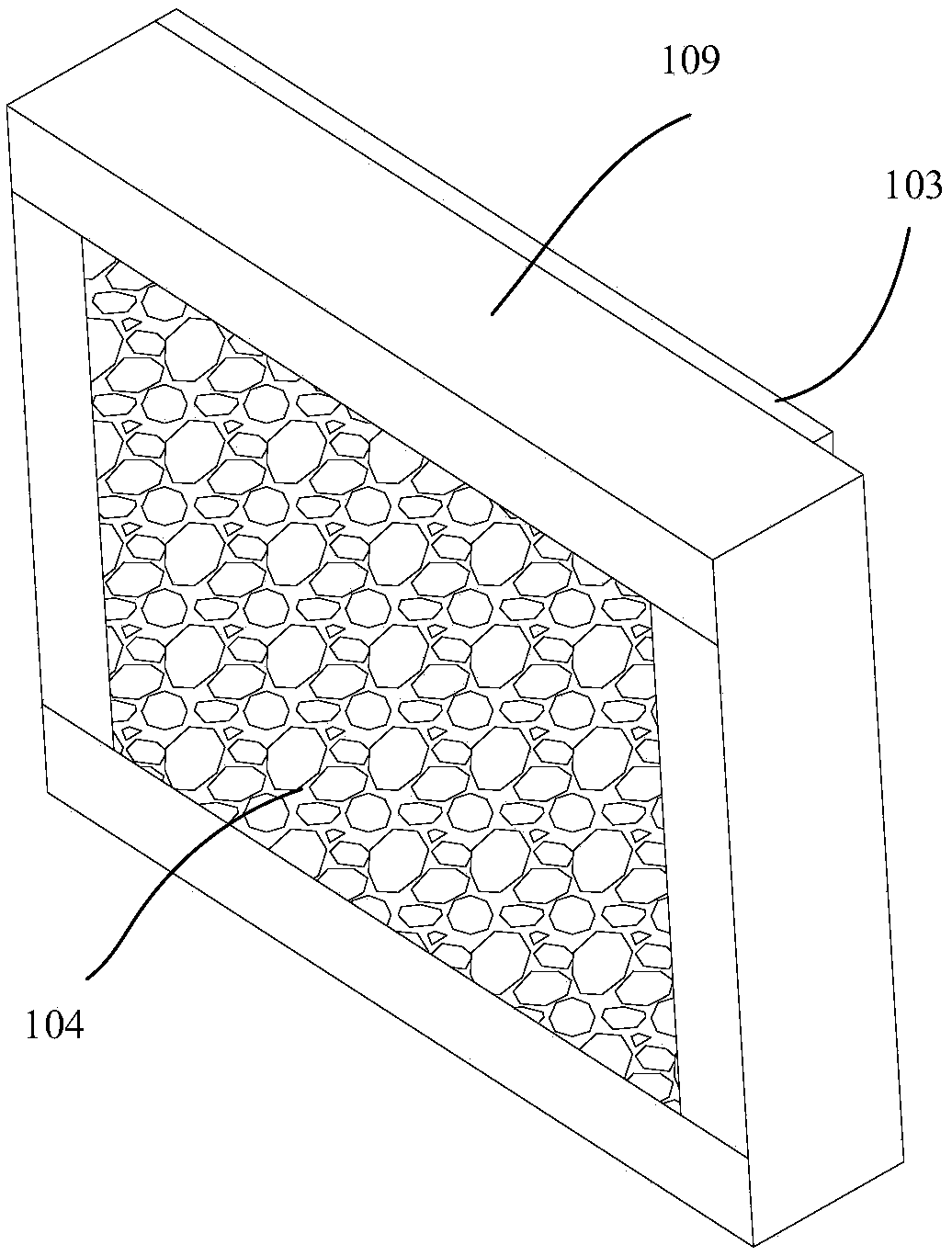

[0035] Figure 1 to Figure 5 It is Embodiment 1 of the assembled wall body of the present invention. Such as Figure 1 to Figure 5 As shown, the prefabricated wall includes a plurality of wall units 1 that are linearly joined together, wherein the wall unit 1 includes a keel frame 109 and wall panels 103 that are arranged on both sides of the keel frame 109 to close the keel frame 109, and The thermal insulation material 104 is filled in the keel frame 109 , and the thermal insulation material 3 is bonded to the wall panel 103 . In particular, the two ends in the length direction of the wall unit 4 respectively form a protruding end 106 and a recessed end 105 for insertion. The prefabricated wall is spliced by the wall units in sequence, which can realize fast and convenient assembly, dry construction, water saving and energy saving, fast and efficient, improve construction efficiency by more than 70%, and can also reduce garbage pollution on the construction site, and has...

Embodiment 2

[0040] Image 6 It is the second embodiment of the fabricated wall of the present invention. The substantial difference between the second embodiment and the first embodiment is that the keel frame also includes vertical keels.

[0041] Specifically, as Image 6 As shown, the keel frame 109 also includes a vertically arranged vertical keel 3, which is parallel to the first keel 101 and the second keel 102, and the two ends of the vertical keel 3 are respectively fixed to two horizontal keels 108 arranged up and down. .

[0042] Compared with the first embodiment, this embodiment can improve the overall strength.

Embodiment 3

[0044] Figure 7 It is the third embodiment of the prefabricated wall of the present invention. The substantial difference between the third embodiment and the first embodiment is that: there is also a filling material between the wall units.

[0045] Specifically, as Figure 7 As shown, a filling material 4 is sandwiched between two adjacent wall units 1, and the filling material 4 is arranged in the gap between the first keel 101 and the second keel 102 of the adjacent wall unit 1, and The first keel 101 and the second keel 102 press the filling material 4 to block the sound propagation path between the two wall units 1 and play a certain role of heat insulation. The filling material 4 is pre-fixed at the joint of any wall unit 1 before the two wall units 1 are joined, and after the two wall units 1 are joined, the two wall units 1 squeeze the filling material 4 .

[0046] Compared with the first embodiment, this embodiment can improve the overall sound insulation perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com