A cam-pressurized cone-disk continuously variable transmission

A continuously variable transmission, cone-disc technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, transmission, etc., can solve the problems of difficult to achieve flexible elements, asymmetry of pressurized cam mechanism, asymmetry, etc. Achieve the effect of compact structure, improved power density and improved lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

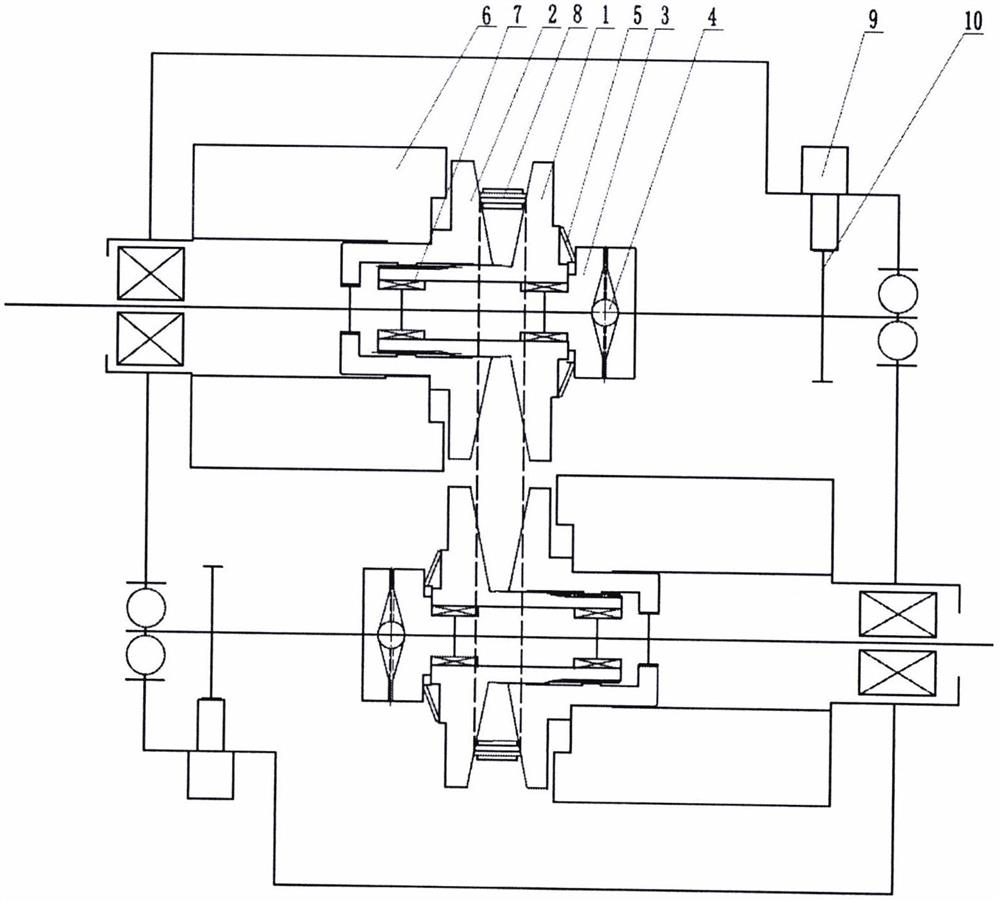

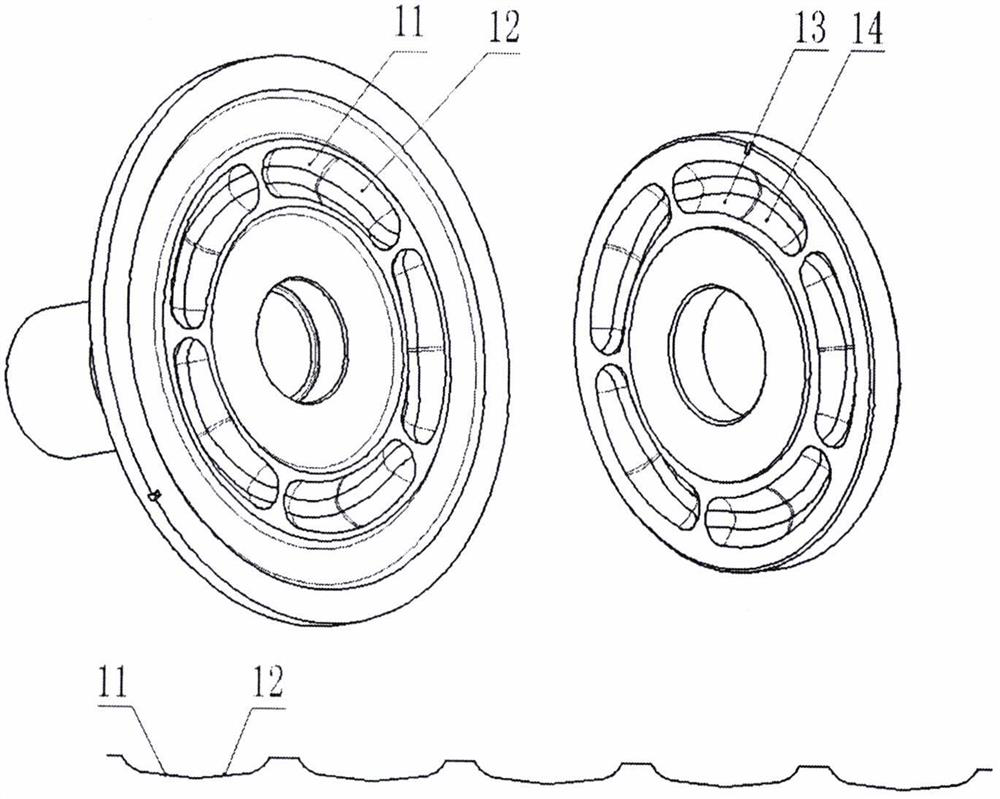

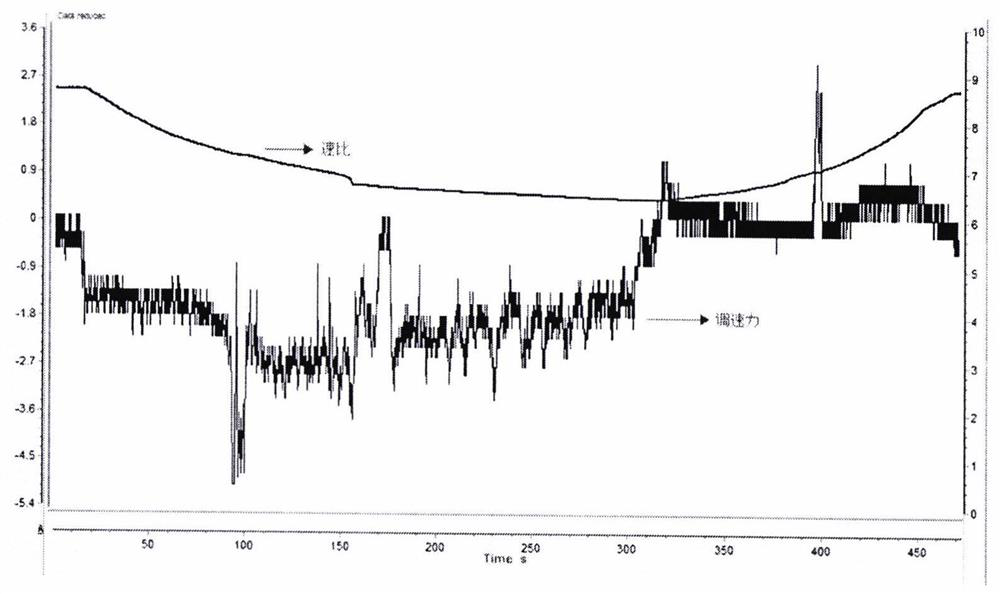

[0052] A cam-pressurized conical-disk type continuously variable transmission, comprising a driving conical-disc group arranged on a driving shaft, a driven conical-disk group arranged on a driven shaft, an end face cam pressurizing mechanism and a steel chain, the The active cone group includes an active fixed cone and an active driven cone, and the driven cone group includes a driven fixed cone and a driven driven cone, and the active and driven cone groups are respectively Working with the steel chain in lubricating oil environment, the back of the driving fixed cone and the driven fixed cone are equipped with an end cam pressurization mechanism, and the end cam pressurization mechanism includes a driving cam and a slave cam arranged axially opposite As for the movable cam, n V-shaped raceways uniformly distributed along the circumferential direction are respectively provided on the axially opposite end surfaces of the driving cam and the driven cam, and each of the V-shaped...

Embodiment 2

[0062] A cam-pressurized conical-disk type continuously variable transmission, comprising a driving conical-disc group arranged on a driving shaft, a driven conical-disk group arranged on a driven shaft, an end face cam pressurizing mechanism and a steel chain, the The active cone group includes an active fixed cone and an active driven cone, and the driven cone group includes a driven fixed cone and a driven driven cone, and the active and driven cone groups are respectively Working with the steel chain in lubricating oil environment, the back of the driving fixed cone and the driven fixed cone are equipped with an end cam pressurization mechanism, and the end cam pressurization mechanism includes a driving cam and a slave cam arranged axially opposite As for the movable cam, n V-shaped pressure surfaces uniformly distributed along the circumferential direction are arranged on the axially opposite end surfaces of the driving cam and the driven cam, and each of the V-shaped pre...

Embodiment 3

[0066] A cam-pressurized conical-disk type continuously variable transmission, comprising a driving conical-disc group arranged on a driving shaft, a driven conical-disk group arranged on a driven shaft, an end face cam pressurizing mechanism and a steel chain, the The active cone group includes an active fixed cone and an active driven cone, and the driven cone group includes a driven fixed cone and a driven driven cone, and the active and driven cone groups are respectively Working with the steel chain in lubricating oil environment, the back of the driving fixed cone and the driven fixed cone are equipped with an end cam pressurization mechanism, and the end cam pressurization mechanism includes a driving cam and a slave cam arranged axially opposite As for the movable cam, n V-shaped raceways uniformly distributed along the circumferential direction are respectively provided on the axially opposite end surfaces of the driving cam and the driven cam, and each of the V-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com