Water jacket cooling water system for falling tank and feeding platform of garbage incinerator

A waste incinerator and cooling water system technology, applied in the direction of incinerators, cooling fluid circulation devices, combustion types, etc., can solve problems such as difficult to apply, easy scaling at the bottom, complex structure, etc., to reduce maintenance costs and improve flow efficiency , the effect of solving the scaling problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

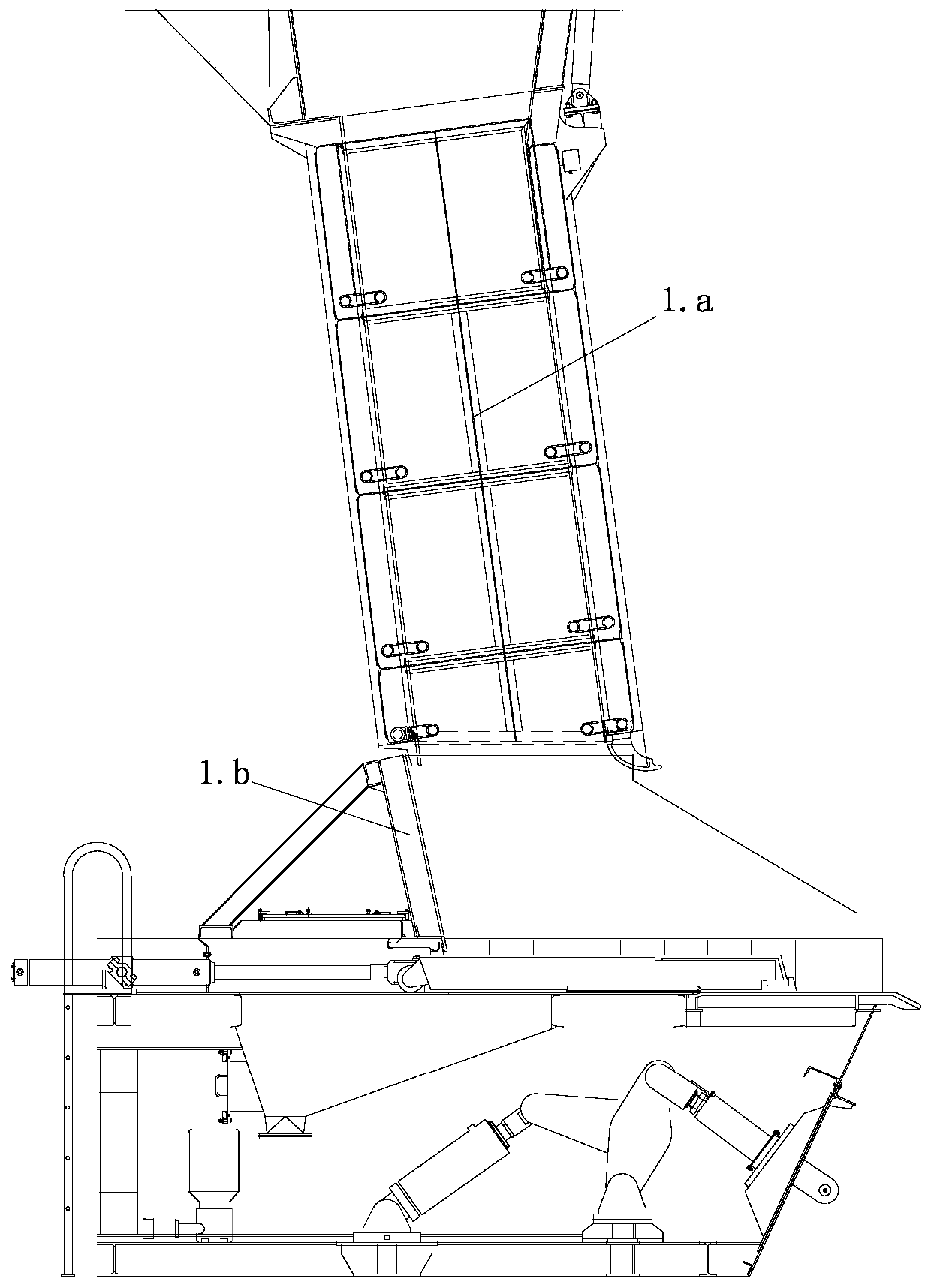

[0038] Such as figure 1 As shown, a water jacket cooling water system for a waste incinerator blanking chute and a feeding platform, including a vertically arranged blanking chute 1.a and a feeding platform 1.b, and feeding to the blanking chute and the feeding platform respectively Water circulation mechanism.

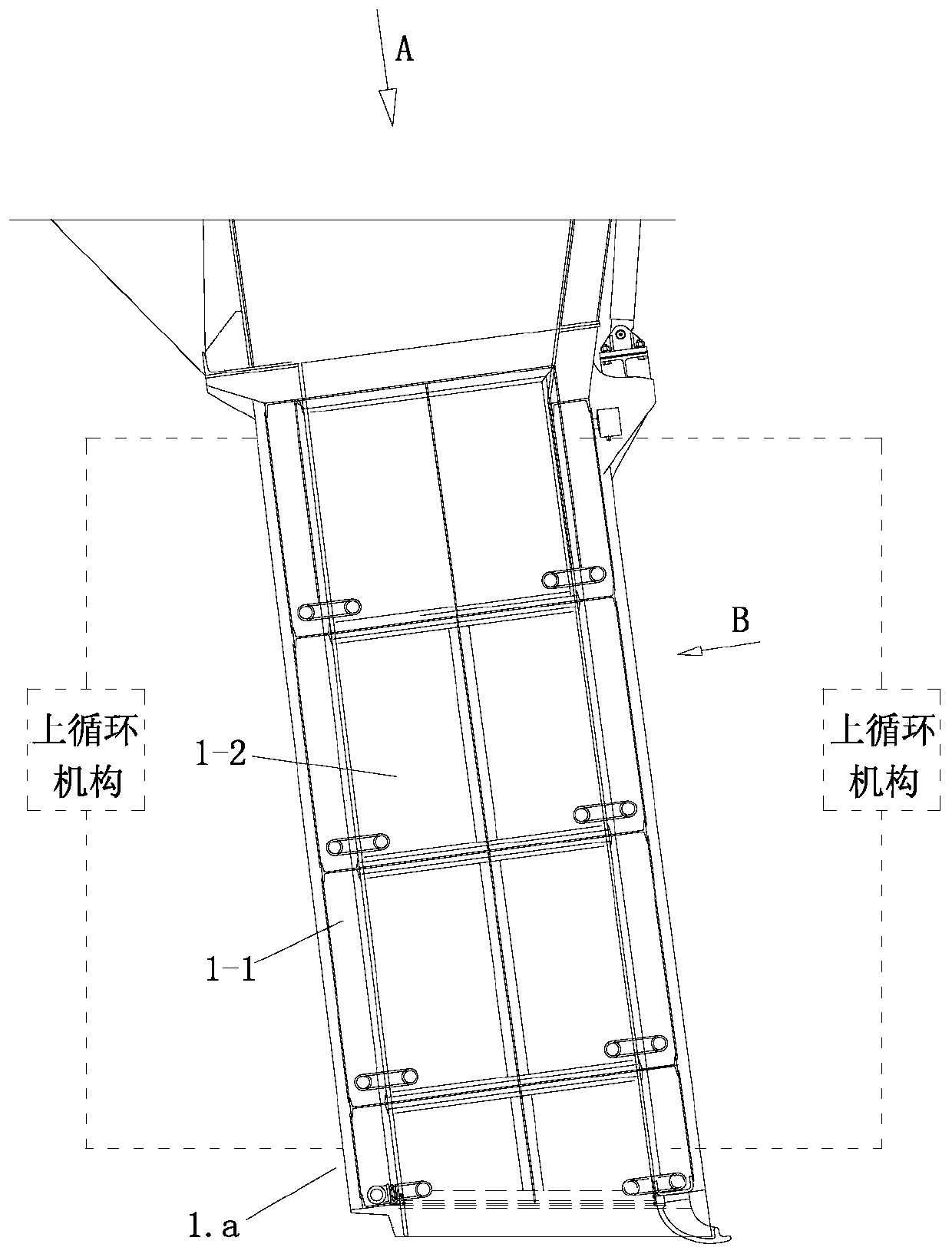

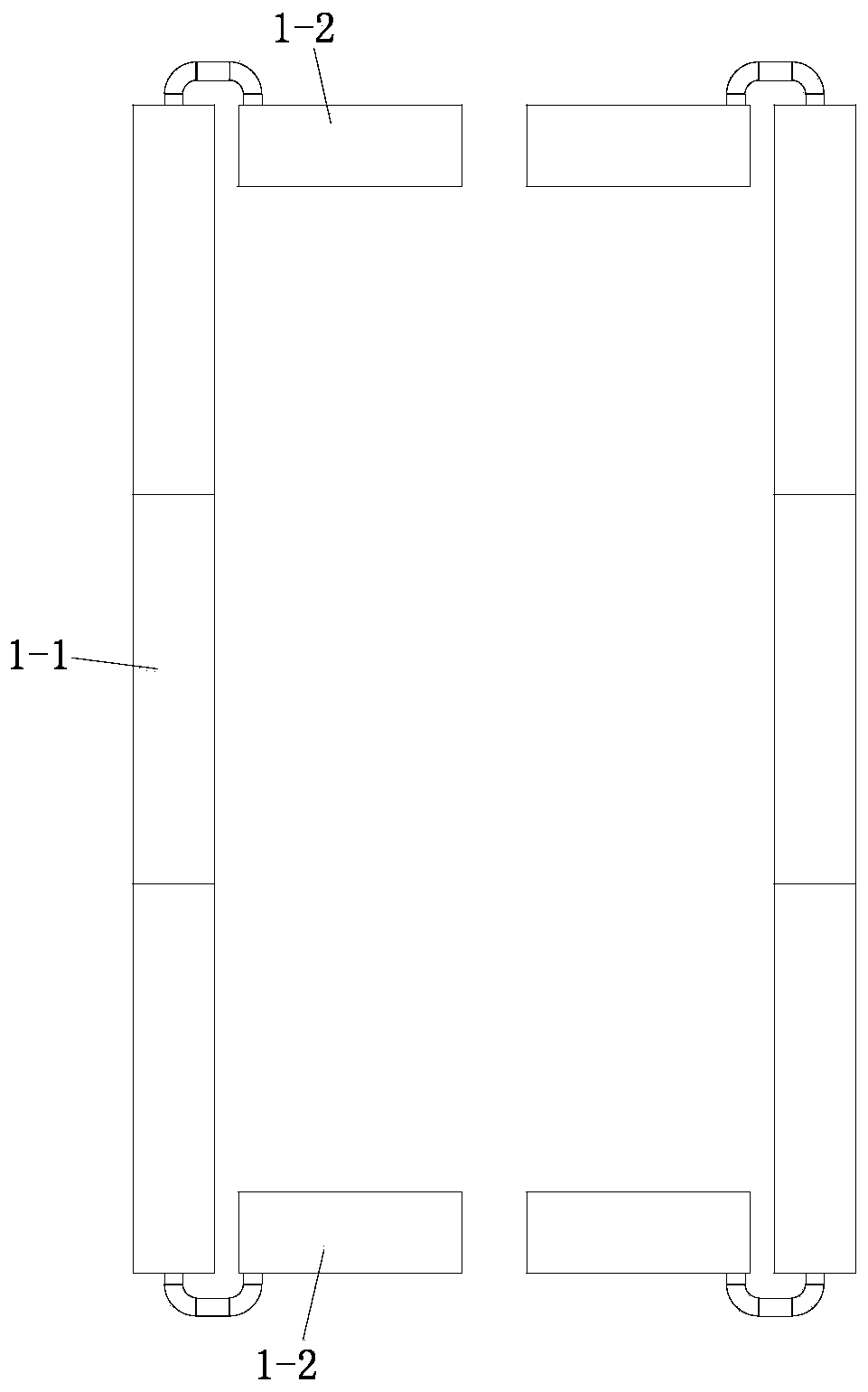

[0039] Such as Figure 2 to Figure 7 As shown, the drop chute includes two symmetrically arranged upper water jacket wall plates. Several upper water flow channels are arranged in the water jacket wall plate, and these upper water flow channels are arranged horizontally and along the height direction of the upper water jacket wall plate ( Figure 4 The vertical direction) is arranged, and the cooling water can flow along the upper water flow channel. Each of the upper water flow channels i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com