Wind-load-resisting type spot type condenser

A concentrator and point-type technology, applied in the field of solar energy applications, can solve the problems of weakening the blowing force of the concentrator, focusing failure, tracking failure, etc., and achieve the effect of improving overall energy efficiency, improving tracking accuracy, and facilitating large-scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

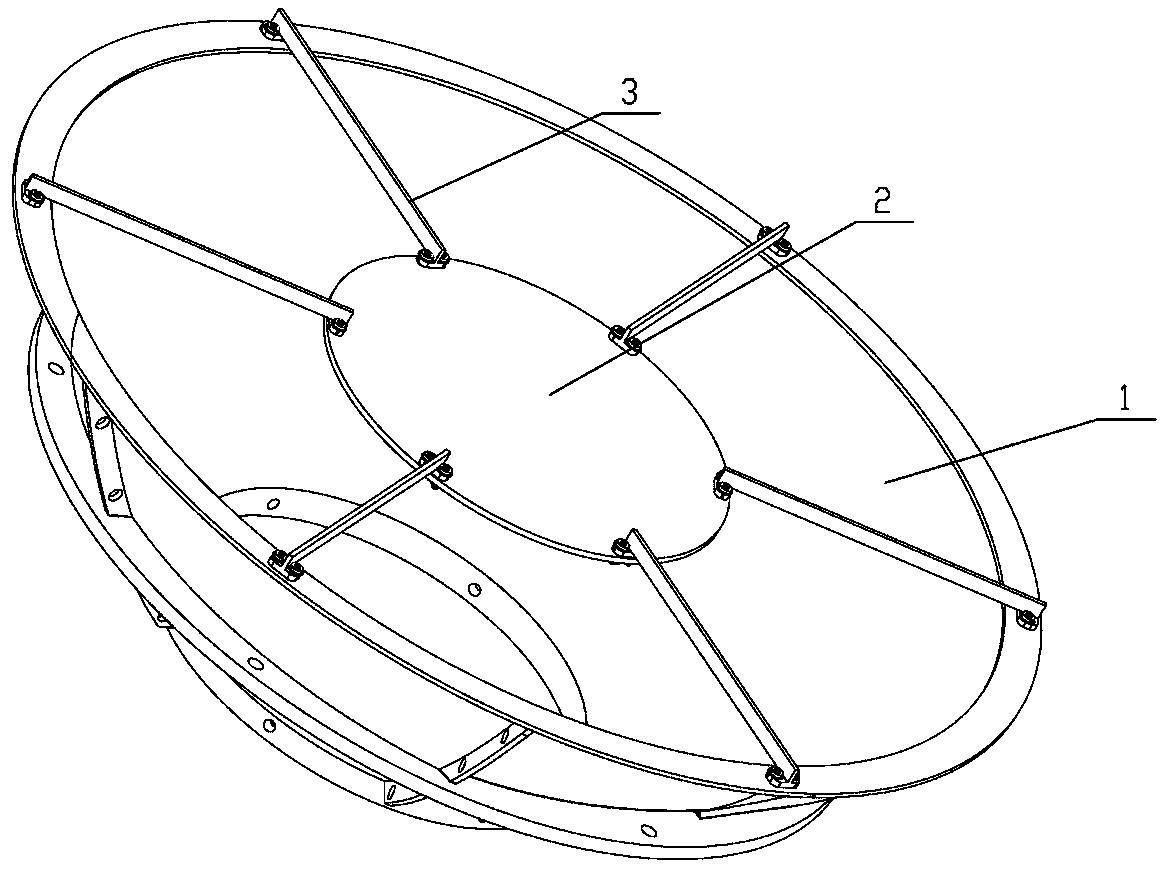

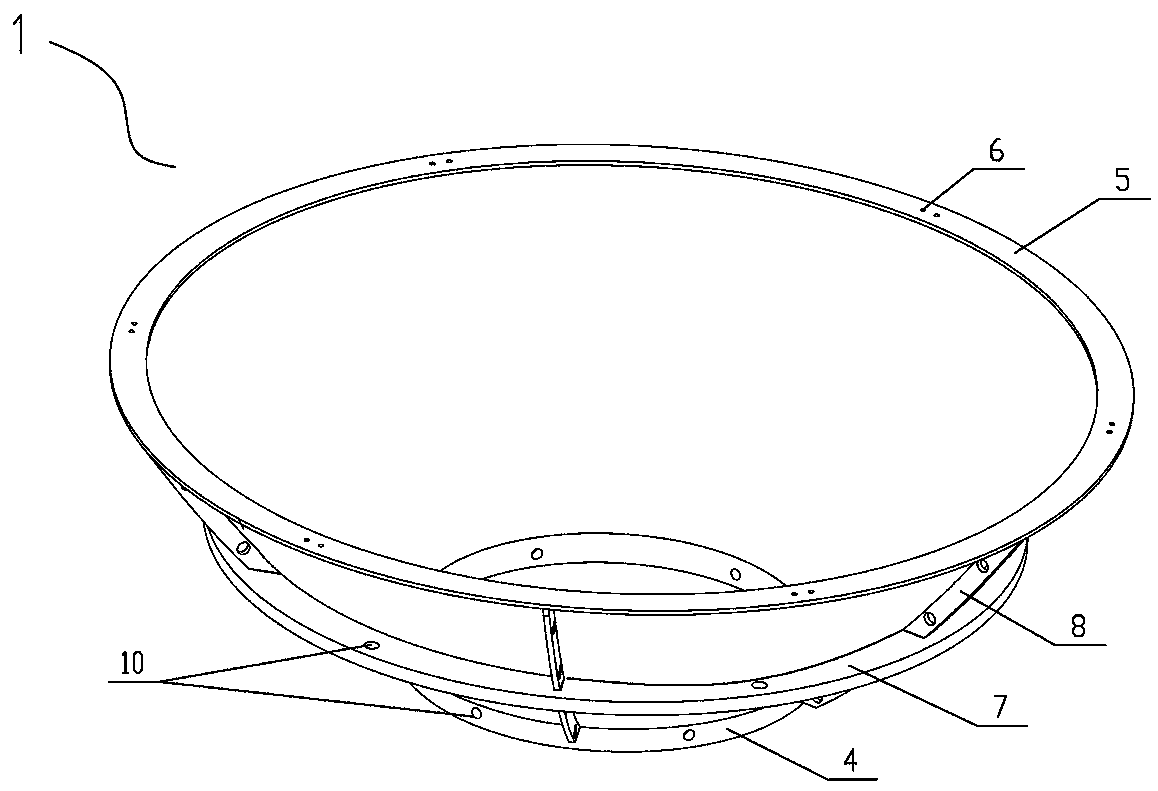

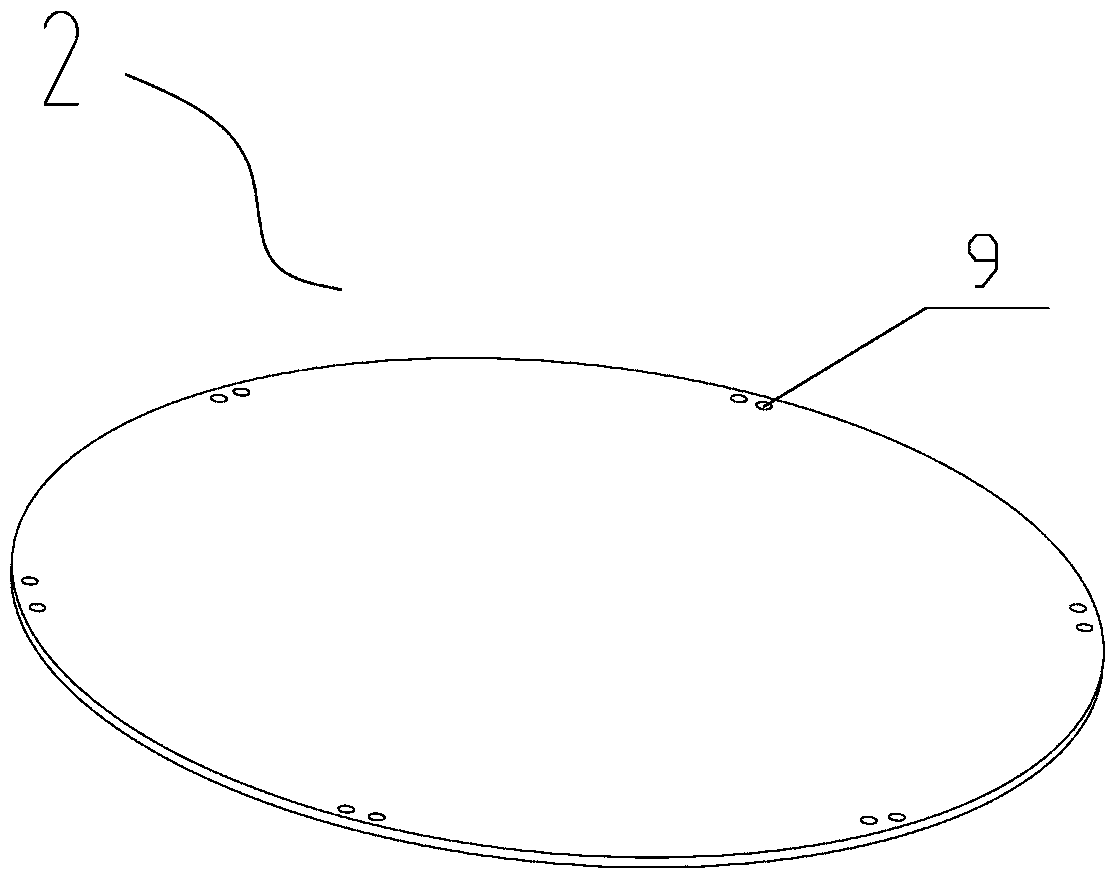

[0021] Embodiment 1: When the present invention is in use, the diameter of the lens of the transmission concentrating component 2 is 0.8 meters, the focal length is 0.75 meters, and the diameter of the open end opening 5 of the paraboloid of the reflective concentrating component 1 is 2.8 meters, and the present invention is installed. On the device that can automatically track both north-south and east-west directions, under the wind condition of grade 4-5 southeast wind, compared with other concentrators with no airflow channel on the overall light receiving surface, the focal spot of the sun light is focused. The deviations in the north-south and east-west directions are greatly reduced throughout the day, that is, the focus fluctuation of the wind blowing from the light facing side to the present invention is small. When concentrating light in the present invention, the open end opening 5 of the reflective concentrating member 1 faces the sun, the central axis of symmetry o...

Embodiment 2

[0022] Embodiment 2: The present invention is installed on the automatic tracking device, the diameter of the open end opening 5 of the paraboloid of the reflective light-converging component 1 used is 2.8 meters, the diameter of the top opening 4 is 0.8 meters, and the lens of the transmission light-converging component 2 is 0.8 meters. The outer diameter is 0.8 meters, and the focal length is 0.75 meters. In early winter, when the northwest wind is 4~5, the condenser can be located at the focal point (spot) of the condenser between 11:30 a.m. and 12:30 p.m. 20 kg of water with an initial temperature of 16 °C was heated to 98 °C in 30 minutes.

[0023] The invention overcomes the shortcoming that point-type focusing can only be achieved by multiple reflection and transmission, adopts the optical path principle of coincidence of transmission and reflection focal points, and directly achieves the point-type focusing purpose only by changing the optical path once. The tracking a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com