Seal ring

A sealing ring and shell technology, which is applied to the sealing of engines, engine components, mechanical equipment, etc., can solve the problems of reduced sealing performance, unstable sealing performance, and changes in contact areas, so as to reduce sliding resistance and stabilize sealing performance The effect of reducing and reducing the torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, modes for implementing the present invention will be described in detail based on examples with reference to the drawings. However, unless otherwise specified, the dimensions, materials, shapes and relative positions of the components described in this embodiment are not intended to limit the scope of the present invention thereto.

[0031] (Example)

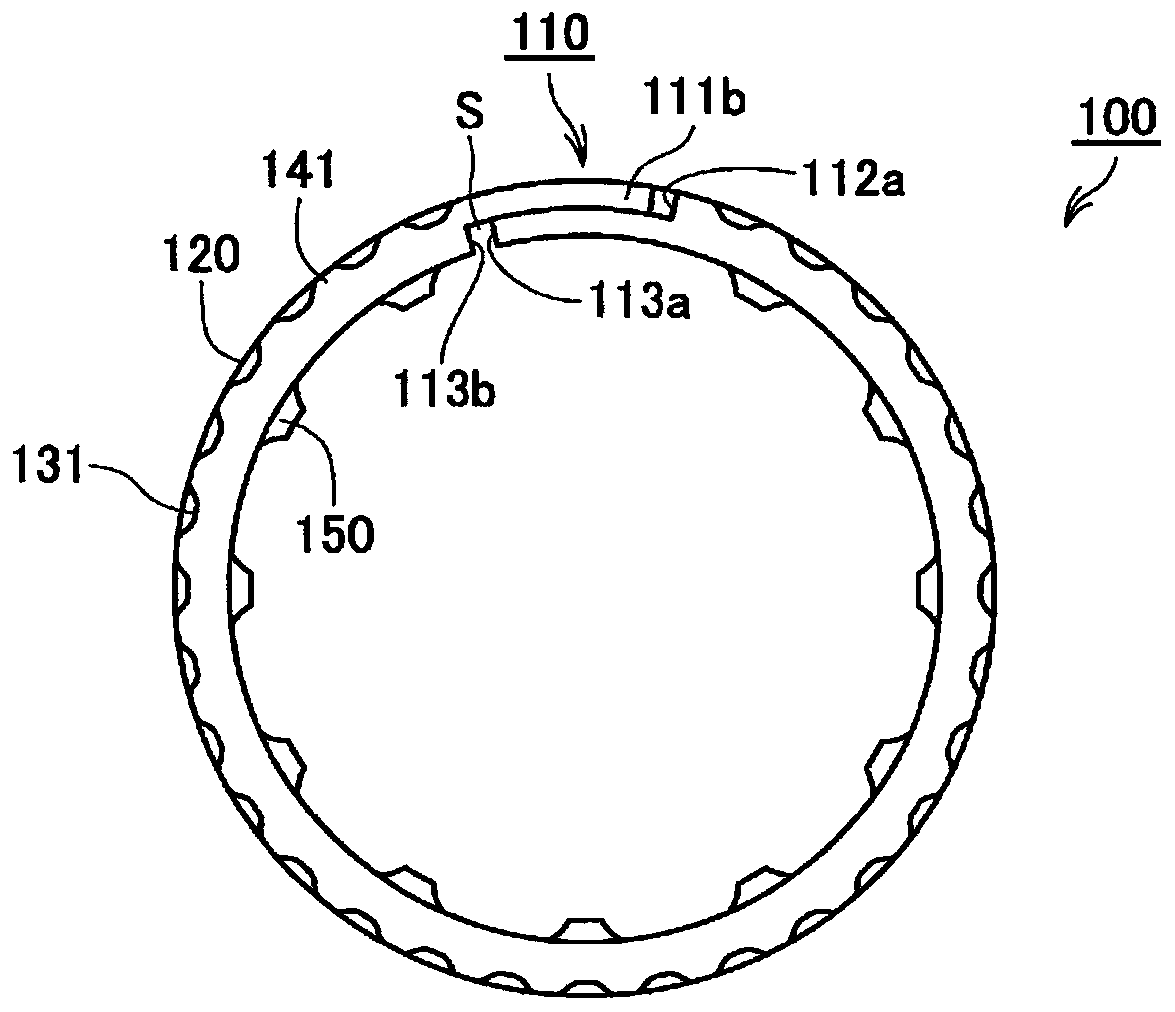

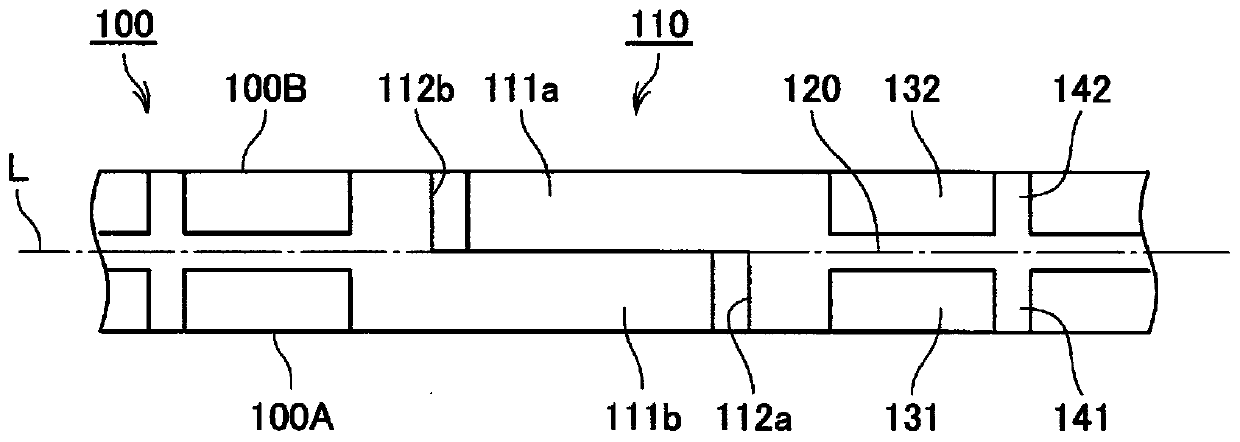

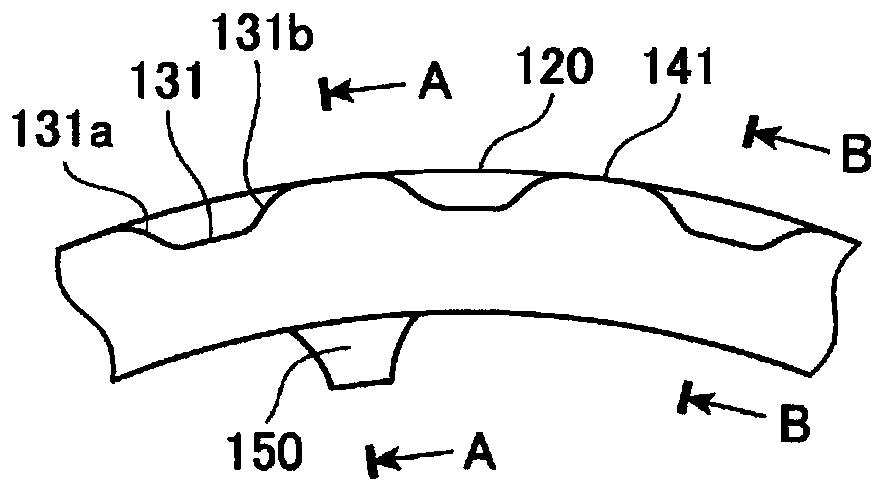

[0032] refer to Figure 1 to Figure 6 The seal ring according to the embodiment of the present invention will be described. figure 1 It is a side view of the sealing ring involved in the embodiment of the present invention. figure 2 It is a part of the figure seen from the outer peripheral surface side of the seal ring according to the embodiment of the present invention, and is a view showing the vicinity of the joint portion provided on the seal ring. image 3 It is a partial enlarged view of the side view of the sealing ring involved in the embodiment of the present invention. Figure 4 ~ Figure 6 It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com