Lens system for use with high laser power density scanning system

A technology of laser power and lens system, used in lasers, laser welding equipment, laser parts and other directions, can solve the problems of high lateral chromatic aberration and increased system distortion of the lens system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

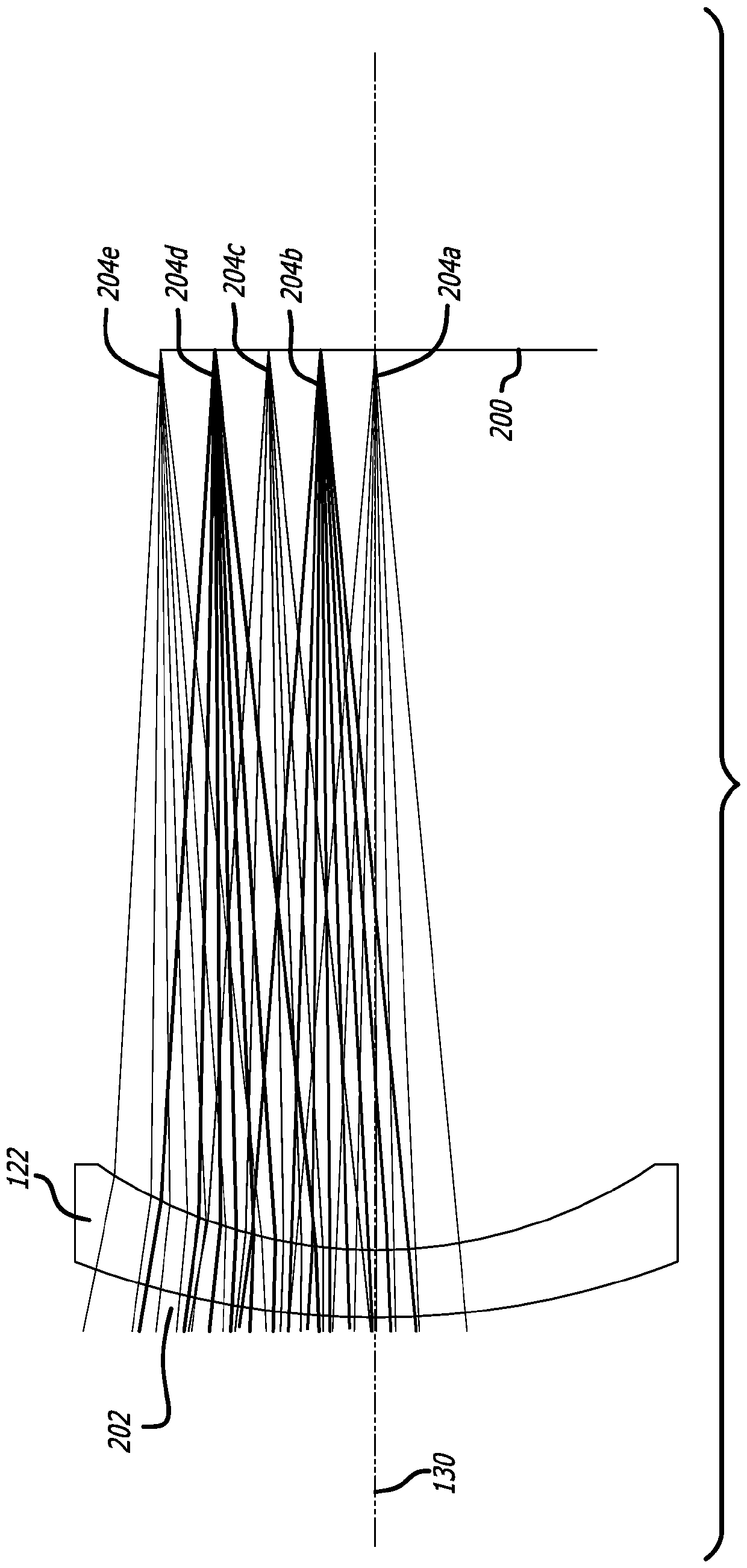

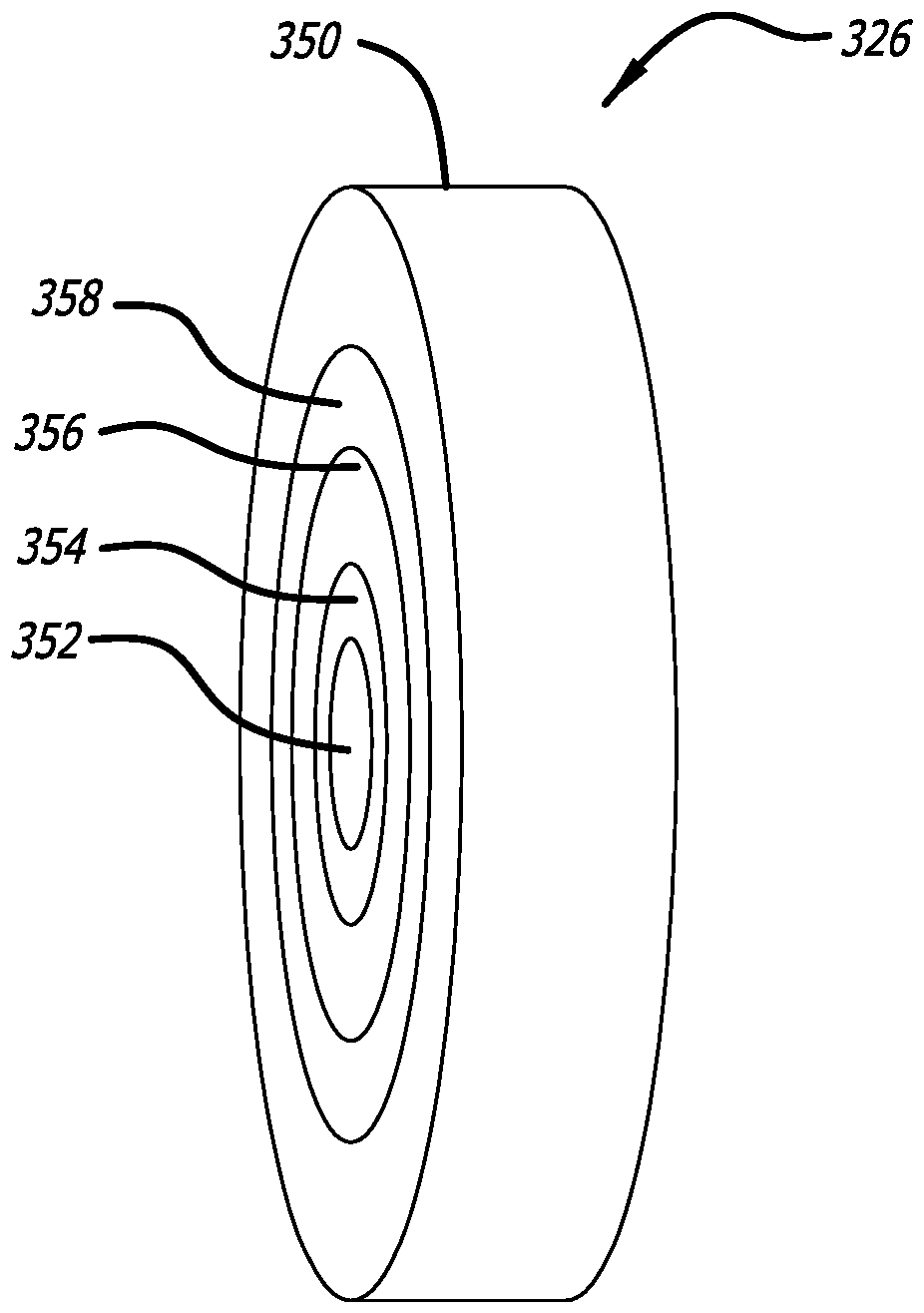

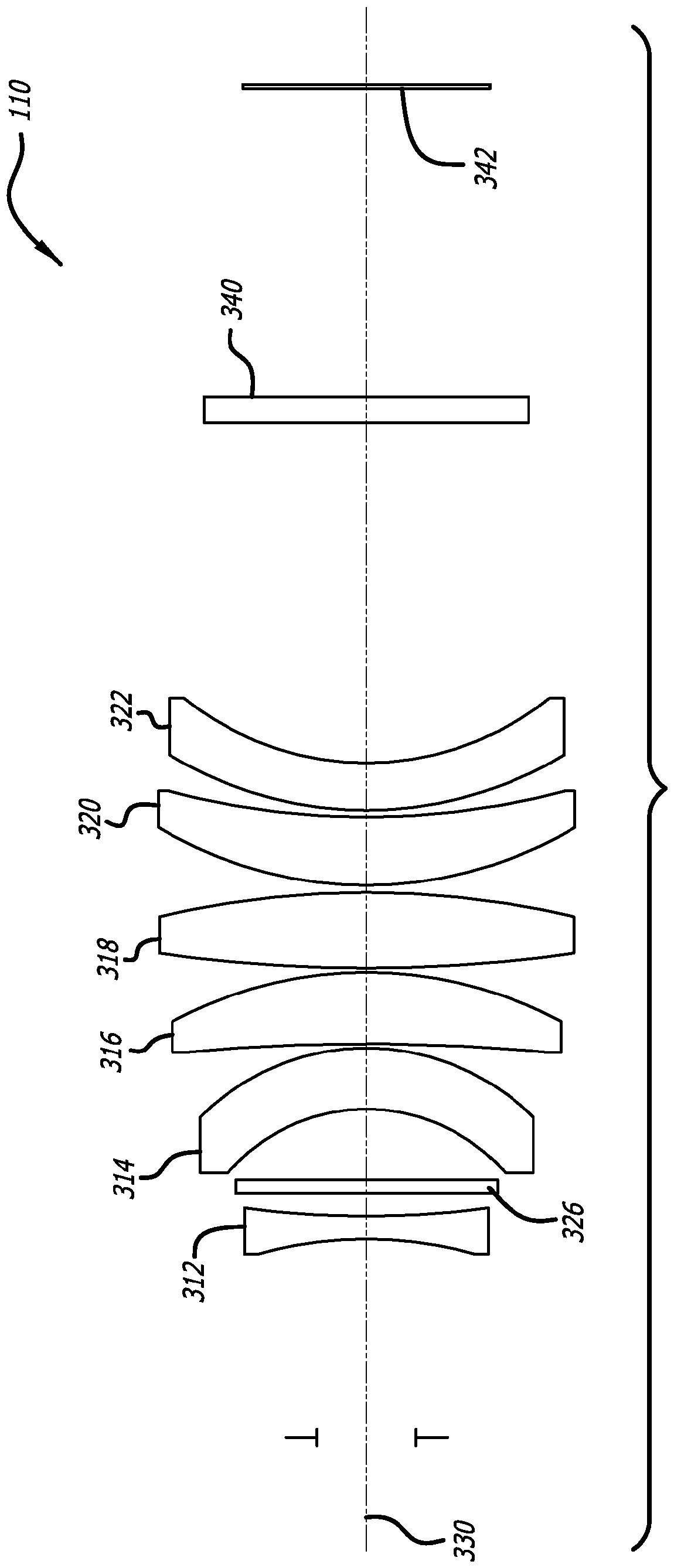

[0024] This application relates to lens systems used in high laser power density scanning systems. More specifically, the lens system may be used in conjunction with a high laser power density scanning system to form one or more features, voids and / or holes in one or more workpieces or surfaces. For example, in one embodiment, the lens systems disclosed herein can be used to form rough features (features having lateral dimensions greater than about 900 μm) in a workpiece. In another embodiment, the lens systems disclosed herein may be used to form features, holes, etc. in a workpiece having lateral dimensions of about 1 μm to about 900 μm. Alternatively, the lens systems disclosed herein may be used to form features, holes, etc. having lateral dimensions of about 5 μm to about 100 μm on the surface of a workpiece. In another embodiment, the lens system disclosed in this application can be used to form features, holes, etc. having lateral dimensions of about 10 μm to about 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap