Material evaporator with liquid level balancing function

A technology of liquid level balance and evaporator, which is applied in the field of heat exchange, can solve the problems of affecting heat exchange effect, large space occupation, long overall length, etc., and achieves the effect of compact structure, small space occupation and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

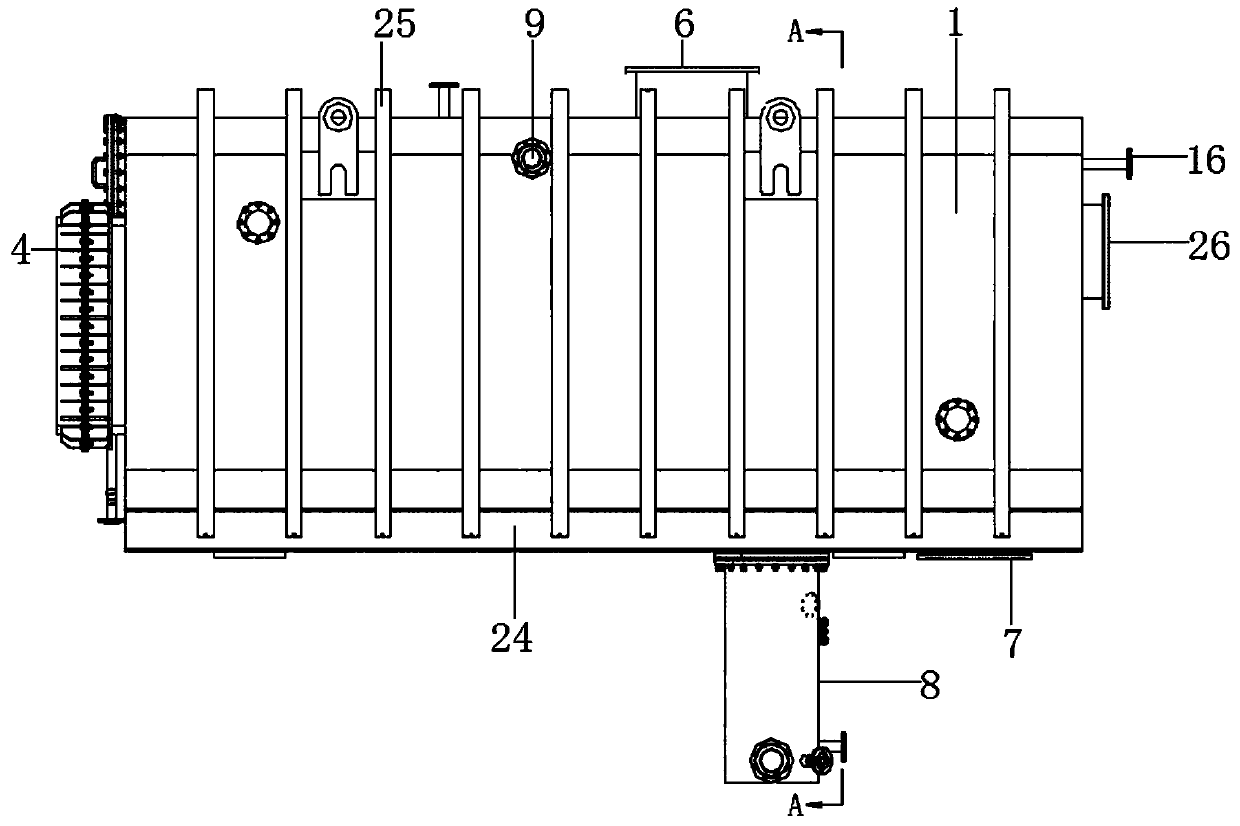

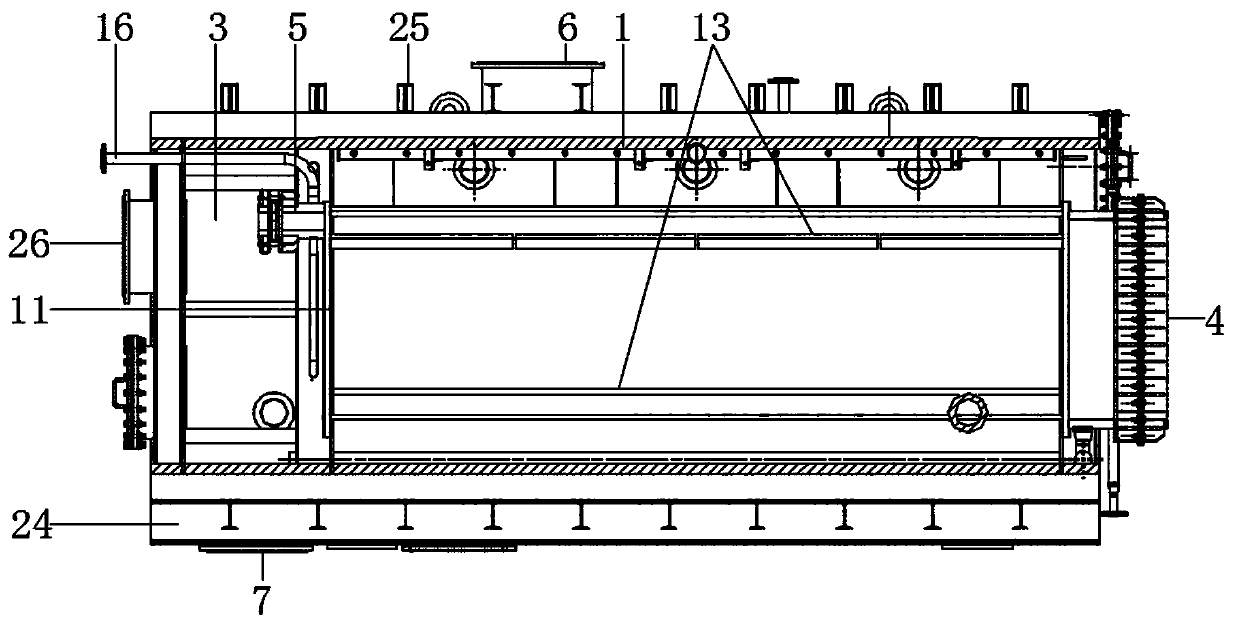

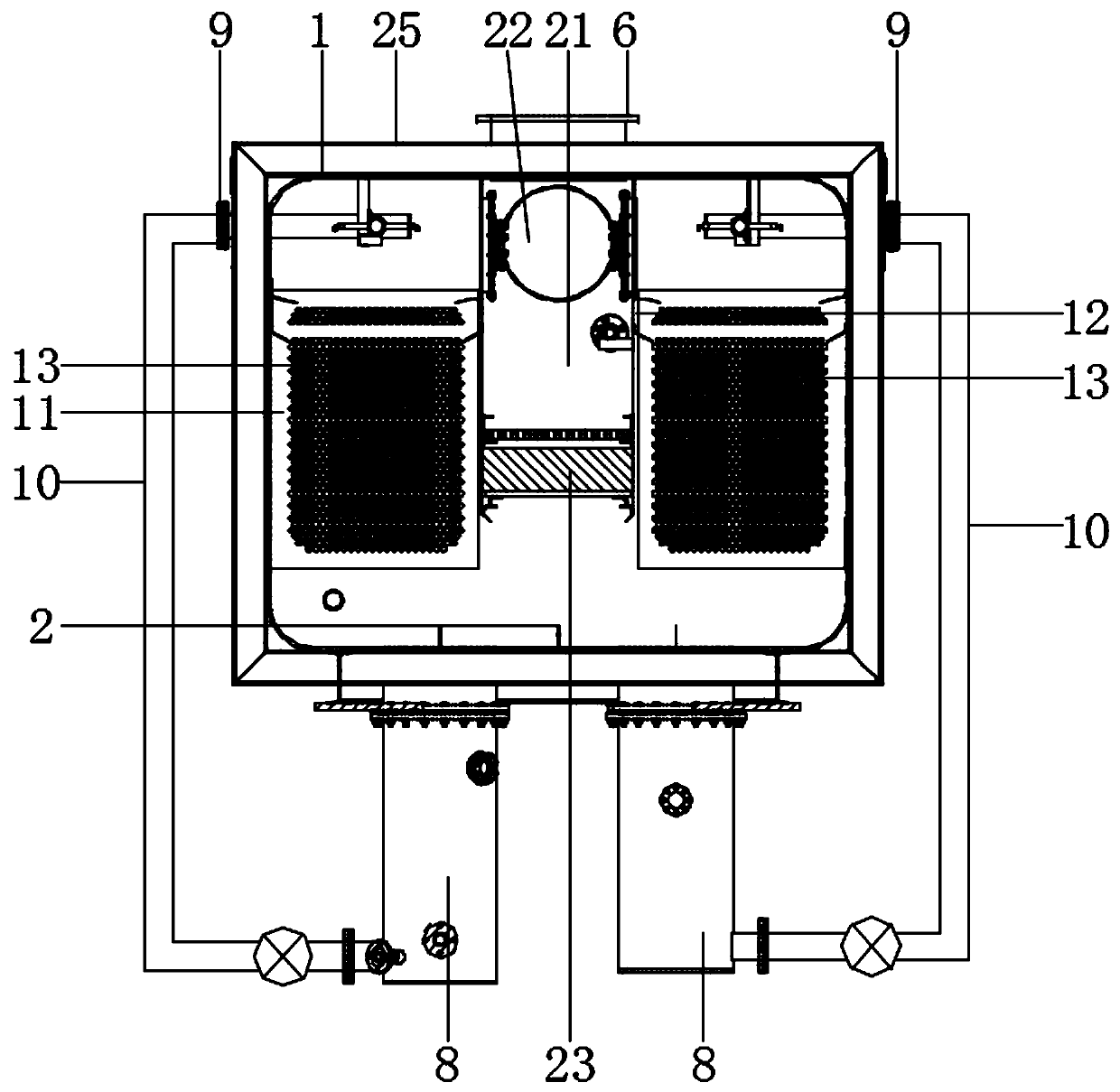

[0035] This embodiment discloses a material evaporator with a liquid level balance function, including a housing 1, wherein:

[0036] The casing 1 is fixed with an overflow plate 2 and two sets of horizontal tube falling film evaporators arranged side by side along the axis line, the overflow plate 2 is located at the bottom of the shell 1, and the two sets of horizontal tube falling film evaporators are respectively located 2 on both sides of the top.

[0037] The horizontal tube falling film evaporation device includes a horizontal tube evaporation mechanism, a steam distribution chamber 3, a steam turning chamber 4 and a U-shaped condensed water discharge mechanism 5, and the steam distribution chamber 3 and the steam turning chamber 4 are respectively located at the steam inlet of the horizontal tube evaporation mechanism. At the end and steam outlet, the U-shaped condensed water discharge mechanism is located in the steam distribution chamber 3, and the U-shaped condensed...

Embodiment 2

[0048] This embodiment discloses a material evaporator with a liquid level balance function, including a housing 1, wherein:

[0049] The casing 1 is fixed with an overflow plate 2 and two sets of horizontal tube falling film evaporators arranged side by side along the axis line, the overflow plate 2 is located at the bottom of the shell 1, and the two sets of horizontal tube falling film evaporators are respectively located 2 on both sides of the top.

[0050] The horizontal tube falling film evaporation device includes a horizontal tube evaporation mechanism, a steam distribution chamber 3, a steam turning chamber 4 and a U-shaped condensed water discharge mechanism 5, and the steam distribution chamber 3 and the steam turning chamber 4 are respectively located at the steam inlet of the horizontal tube evaporation mechanism. At the end and steam outlet, the U-shaped condensed water discharge mechanism is located in the steam distribution chamber 3, and the U-shaped condensed...

Embodiment 3

[0060] This embodiment is basically the same as Embodiment 1 or Embodiment 2, the main difference is:

[0061] The shell 1 is a square structure, and the inherent support channel steel 24 is welded symmetrically at the bottom of the shell 1, and there are many reinforcing ribs 25 uniformly distributed on the outer surface of the shell 1, and the reinforcing ribs 25 can be I-shaped steel, L-shaped steel, or H-shaped steel. , I-beam, etc., the reinforcing rib 25 is welded on the shell 1, and the two ends of the reinforcing rib 25 are respectively welded on two supporting channel steels 24.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com