Aircraft accessory automatic oil seal system and working method

An accessory and aircraft technology, which is applied in the field of aircraft accessories automatic oil seal system, can solve the problems of inability to meet the oil seal requirements of the electromechanical integrated hydraulic system, the oil seal equipment has no power supply system, and the workload is heavy, so as to avoid damage to aircraft accessories and save aviation materials. The effect of maintenance cost and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

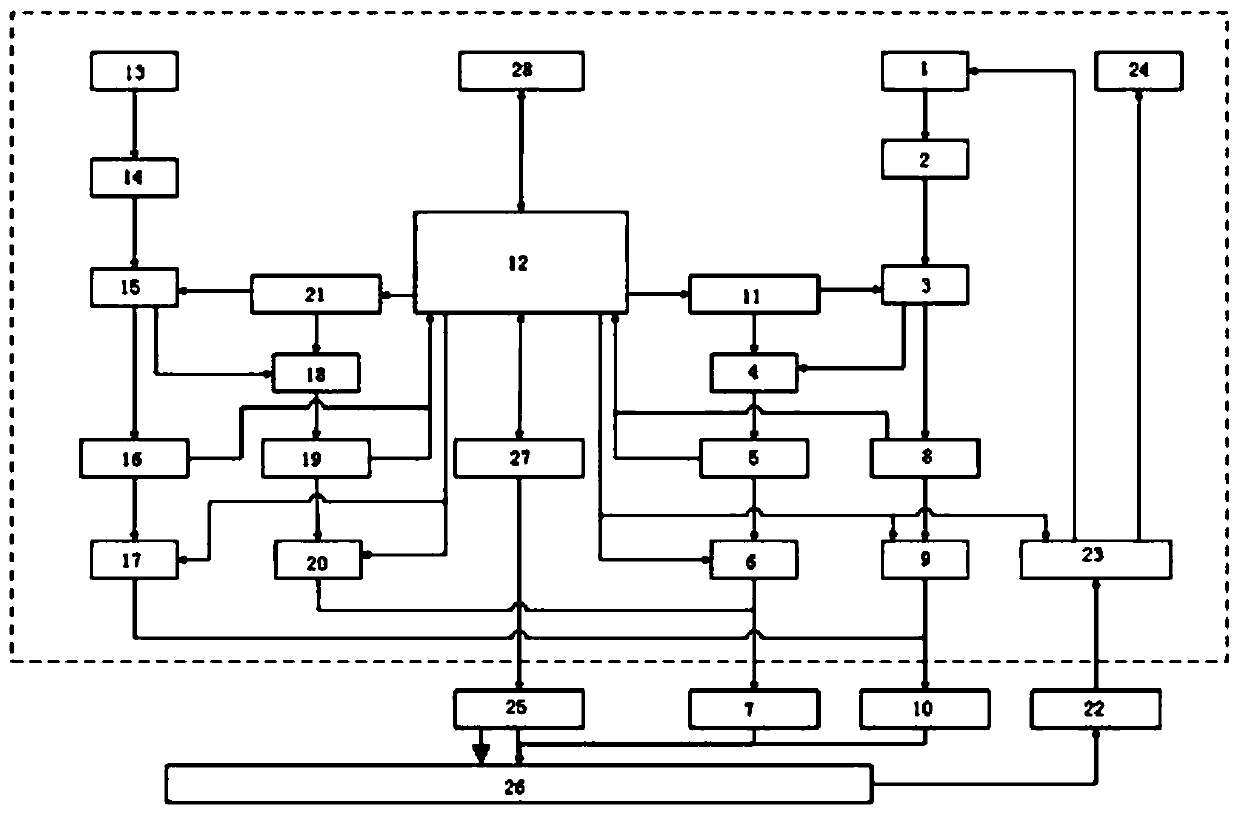

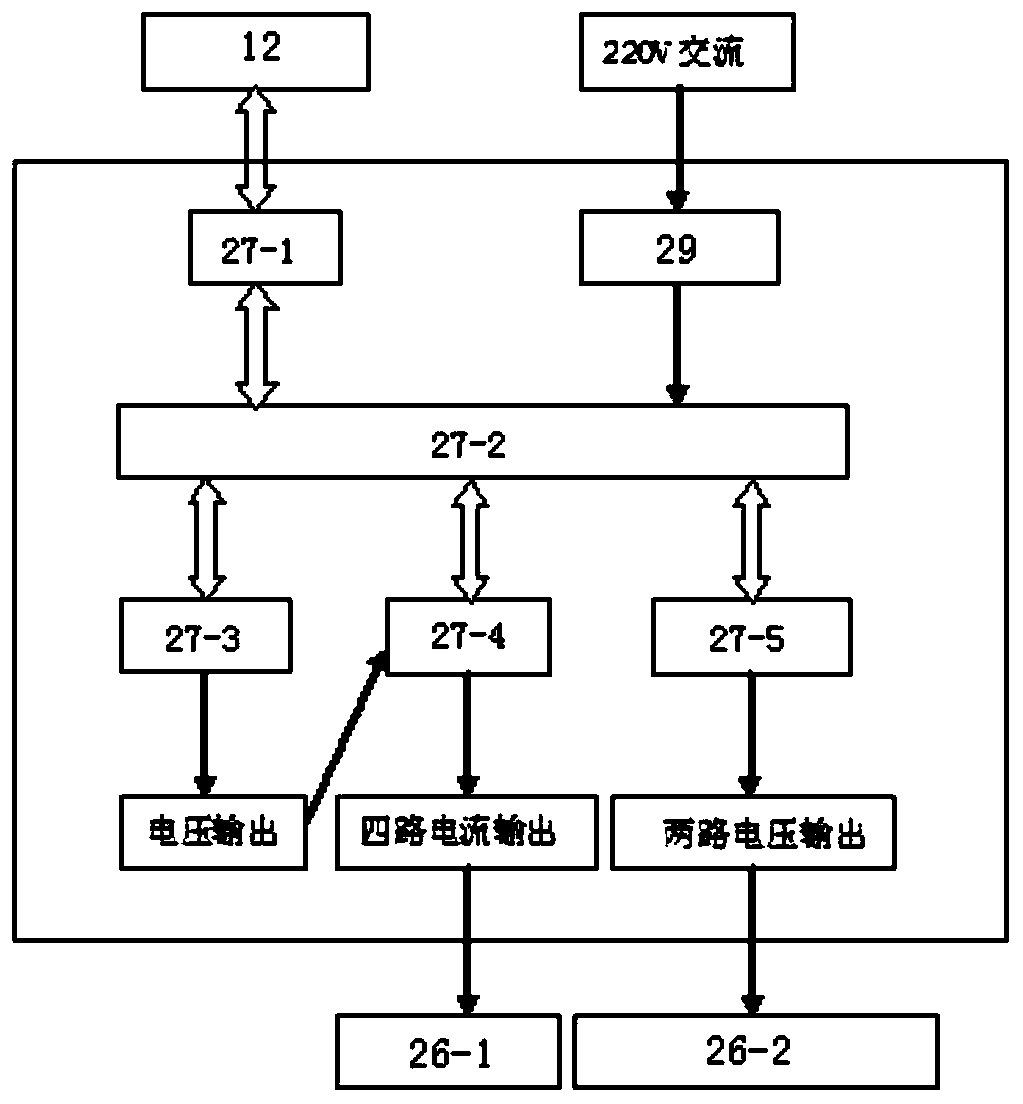

Method used

Image

Examples

Embodiment 2

[0050] This embodiment discloses a working method of an automatic oil seal system for aircraft accessories: including the following steps:

[0051] Step 1: Connect the first cleaning oil pipe and the second cleaning oil pipe to the oil inlet of the aircraft accessory to be oil sealed, and connect the second circuit board and the third circuit board to the servo valve and solenoid of the aircraft accessory through the connecting cable and plug. Valve connection, input the set oil pressure of the first cleaning oil pipe and the second cleaning oil pipe on the touch screen according to the actual situation, and set the set input current of the servo valve of the aircraft accessories and the set input voltage of the solenoid valve on the touch screen to start the cleaning Pump, the cleaning hydraulic oil enters the aircraft accessories to be oil-sealed through the first cleaning oil pipe and the second cleaning oil pipe. The control system controls the first pressure reducing valve an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com