Four-edge milling cutter and manufacturing method

A milling cutter and fine milling technology, which is applied in the field of 4-edged milling cutters and production, can solve the problems of poor chip breaking and chip removal and poor heat dissipation effect of milling cutters, and achieve enhanced chip breaking effect, optimized chip removal effect and heat dissipation effect, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

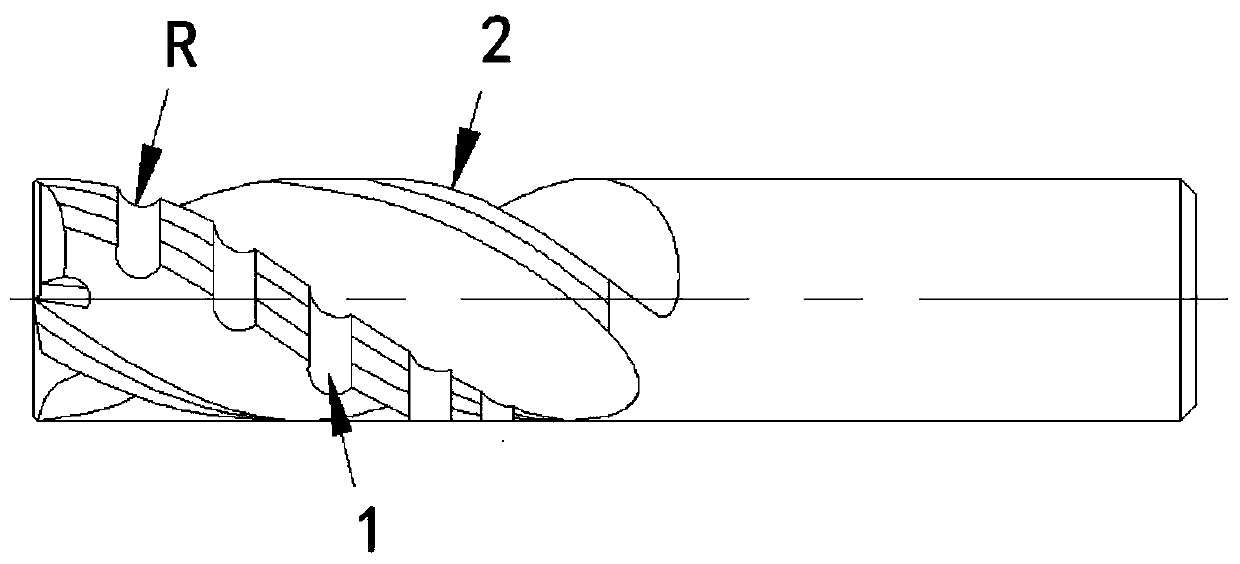

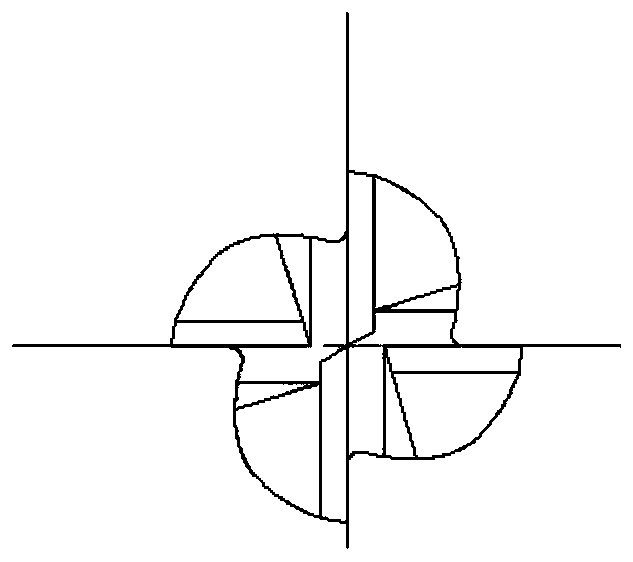

[0016] Embodiment 1: as figure 1 , figure 2 As shown, a 4-edged milling cutter is ground and processed by solid carbide, and has 4 cutting edges 2 in total, of which the symmetrical two edges are finish milling edges, and the other two edges are provided with chip breakers 1 staggered from each other. And according to the different diameters of the milling cutters, the arc radius R of the chip breaker 1 is R0.8-R1.5mm.

[0017] A method for manufacturing a 4-blade milling cutter, comprising the following steps: the 4-blade milling cutter is installed on a fixture, the 4-blade milling cutter can be rotated on the fixture, and the chip breaker 1 is processed by wire electric discharge cutting, and the rotation With a 4-blade milling cutter, move the wire electrode of the wire electric discharge cutting to the position where the chip breaker needs to be processed, process the chip breaker in sequence, and process the arc radius R of the chip breaker 1. The size is R0.8-R1. 5mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com