Tipping bucket type flow control and automatic monitoring gate system and method

A technology of flow control and automatic monitoring, which is applied in liquid/fluid solid measurement, measurement capacity, measurement devices, etc., and can solve the problems of unpopular gate flow control and monitoring technology, high operation and maintenance costs, and large investment in electronic information technology. Achieve the effect of saving manpower, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

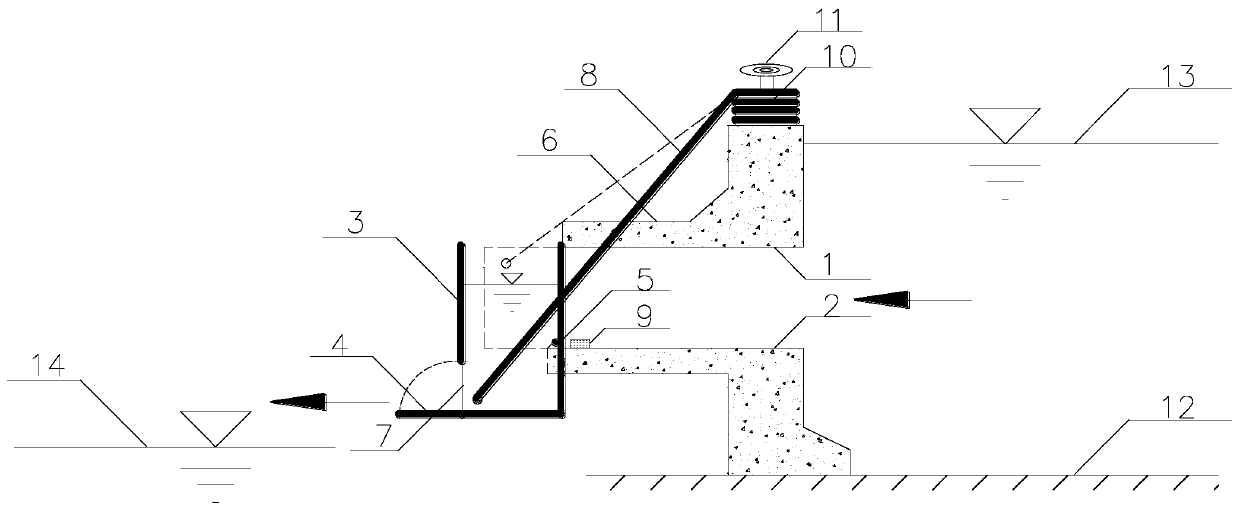

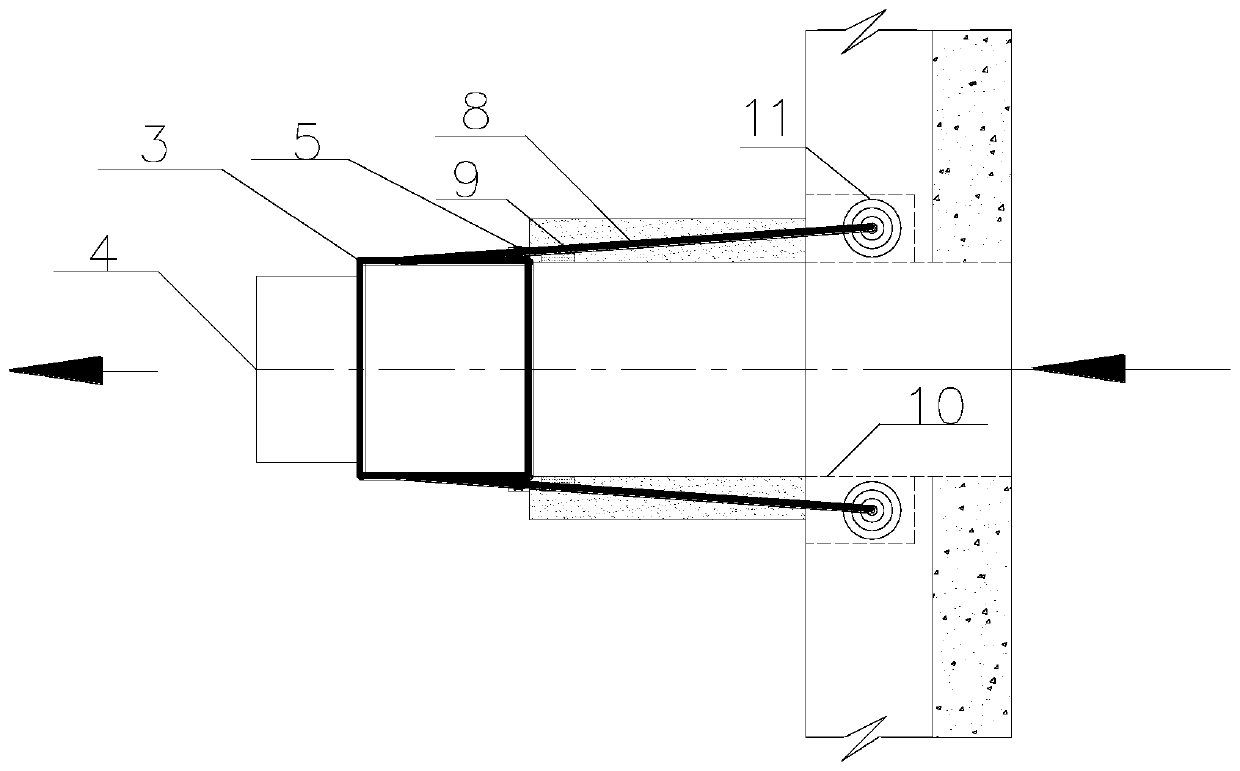

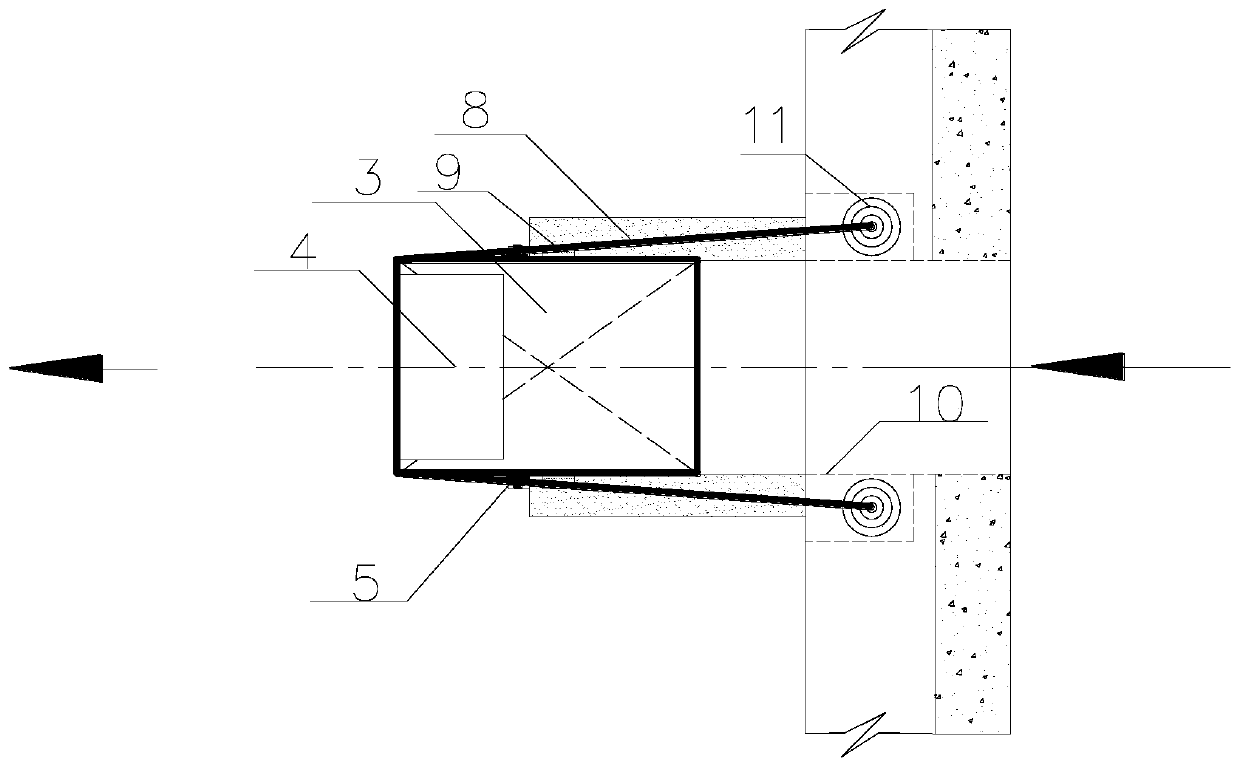

[0025] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0026] Such as figure 1 As shown, the present invention mainly includes: a tipping bucket gate 3, an elastic sling 8, a sling control runner 10, a signal output terminal 9, a lock chamber structure, a gate base 12, etc. The main functions of each structure are specifically described below:

[0027] The tipping bucket gate 3 is set in the gate, the tipping bucket gate 3 is located on the downstream side of the gate, the upstream side of the tipping bucket gate 3 is provided with a water blocking wall across the gate, and a horizontal water blocking wall is provided near the middle and upper part of the gate. The water hole, the downstream side of the water hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com