Light steel and light concrete structure

A light steel and flanging structure technology, which is applied to building components, building structures, walls, etc., can solve the problems of unreasonable matching of opening parameters, reduced bearing capacity and stiffness, and large opening rate of webs. Thermal bridge effect, increased strength, increased flexural stiffness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

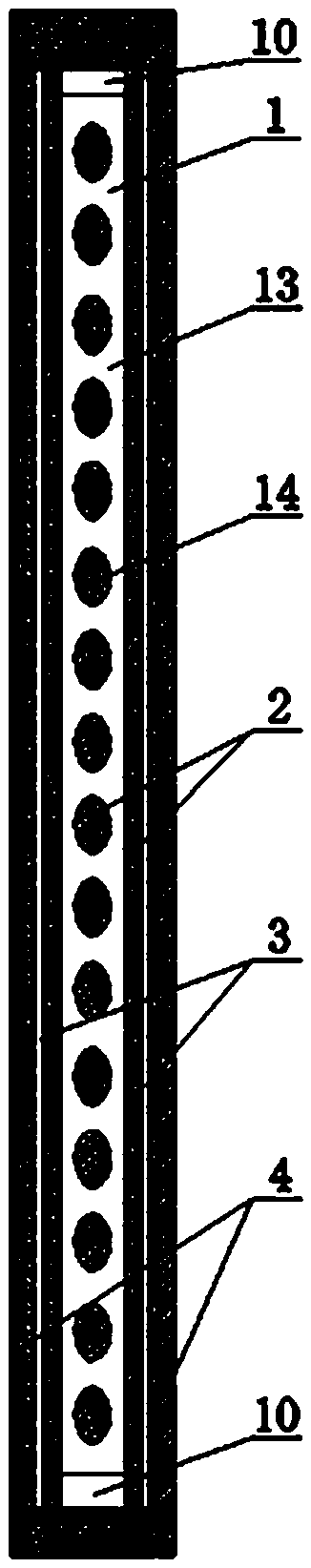

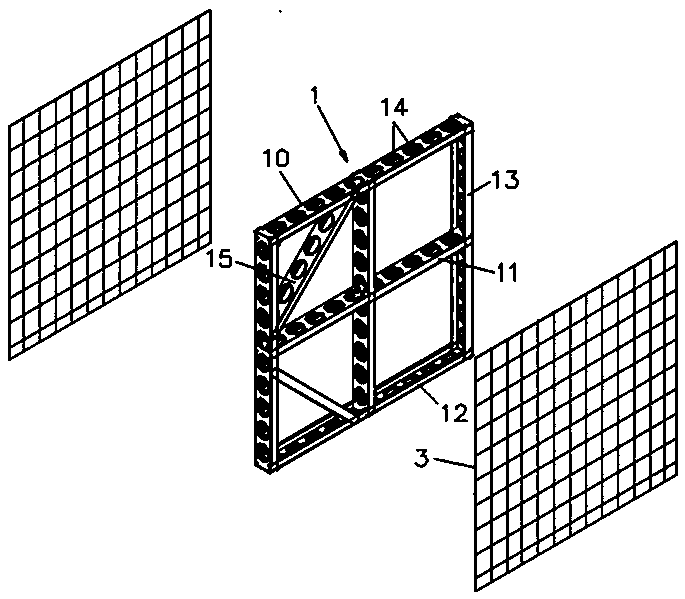

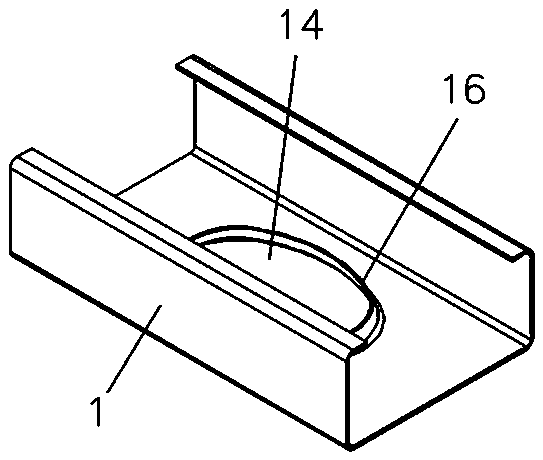

[0024] Such as Figures 1 to 8 As mentioned above, the present invention includes a frame-shaped light steel frame 1, lightweight concrete 2 filled inside and outside the light steel frame 1, the light steel frame 1 includes a horizontal keel 10, and at least one horizontal middle The keel 11, the horizontal ground keel 12, and at least two vertical keels 13 arranged at intervals in the longitudinal direction. The light steel skeleton 1, the sky keel 10, the middle keel 11, the ground keel 12 and the vertical keel 13 are provided with a plurality of elliptical flanging structure reinforcement hole...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap